It’s Men’s Health Week from 12th to 19th June and the

Lighthouse Construction Industry Charity are supporting the week by raising awareness of all the resources they have to support our men in construction.

One in five men die before the age of 65. The causes are a variety of physical and mental health issues, so Men’s Health Week is all about increasing awareness of preventable health problems for men of all ages and backgrounds.

Our construction workforce is 87% male so it is vital that our workforce are given free and easily accessible support to live healthier lifestyles and there are plenty of things that can be done to help stay fit in mind and body.

Physical Health

Get regular check-ups with your doctor. Seeing your GP regularly can help them identify and treat any health issues, such as

Prostate cancer, in its early stage.

Reduce your salt and sugar intake. Having too much salt can increase your cholesterol and cause heart problems later down the line whereas too much sugar can lead to obesity and/or diabetes.

Go for a daily walk. Taking a stroll lets you get in some cardio exercise and fresh air – and it’s great for your mental health.

Reduce alcohol intake. As well as inhibiting your ability to perform day to day functions, consistent and large intakes of alcohol can cause liver problems.

Quit smoking. Smoking is bad for every organ in your body and can lead to a variety of severe health issues, such as lung and throat cancer – it’s also expensive!

Enjoy breakfast everyday – A nutritious breakfast starts your day off right. It not only sets you up so you have energy and fuel for optimal mental and physical performance, but also to maintain stable blood sugar levels and a healthy weight because you are less likely to overindulge later in the day

Mental Health

Join a community group. Being part of a group can boost mental wellbeing by reducing feelings of loneliness and detachment. Try visiting one of our

Lighthouse Beacons as a first step.

Talk to someone. Whether it’s family or friends (or even one of our helpline workers), maintaining healthy relationships with peers. You can always call our

helpline if you need.?

Take up a hobby. Engaging in a hobby can be a mental escape, help us hone a skill, or just provide an opportunity to socialise with others. It’s also a great way to help us disconnect from work and break away from the monotony of daily life.

Volunteer. Doing something selfless for others has been proven to make ourselves feel better. We even have our own

volunteering opportunities you can join.

Get a good night’s sleep. Sleep is essential to healthy mental wellbeing as it helps us regulate our emotions and ability to function effectively. Register for the free

Sleepstation app to find out how.

Adopt relaxation techniques. These can work to slow down breathing, lower blood pressure, and reduce muscle tension and stress.

Bill Hill, CEO of the Lighthouse Construction Industry Charity said,

“Our construction industry is 87% male, which is why it’s incredibly important for us to provide the right support and encourage them to be healthy for work and for life. As a charity we provide holistic support across all aspects of emotional, physical and financial wellbeing and we strive to provide education and information so that where possible people can help themselves and be pro-active in developing a healthy lifestyle. We’ve had a fantastic response to recent campaigns highlighting skin health, stress, prostate cancer and healthy sleeping and we will continue to provide pro-active resources for our workforce.

We’re here for everyone who works in the construction industry and allied trades, including their families, and all our support services are completely free. Whether you want specific advice from one of our trained advisors through our helpline or text support service, or access to learning resources through our Self Support App, there is a route to support for everyone.”

Reaching out for support

- 24/7 Construction Industry Helpline offering free and confidential emotional, physical and financial wellbeing support with translation services for those that need extra support.

- Construction Industry Helpline Self Support App which complements the helpline and signposts to over 3000 accredited organisations offering specialist support.

- Free text HARDHAT service that gives immediate access to text back counselling

- Lighthouse Beacons. 160 volunteer centres across the country that offer a safe place to meet in a confidential environment.

- CPD accredited Wellbeing Masterclasses covering topics such as Managing Stress, Coping with Anxiety and Building Resilience to name just a few.

To access all the resources above and to find out more, visit the charity’s

Mens Health Campaign page

If you need help or support now, or know someone that does, you can access free and confidential support 24/7 via:

Construction Industry Helpline on UK 0345 605 1956 / ROI 1800 939 122

,

Or text HARDHAT to 85258 (UK) or 50808 (ROI)

Website signposting to all resources

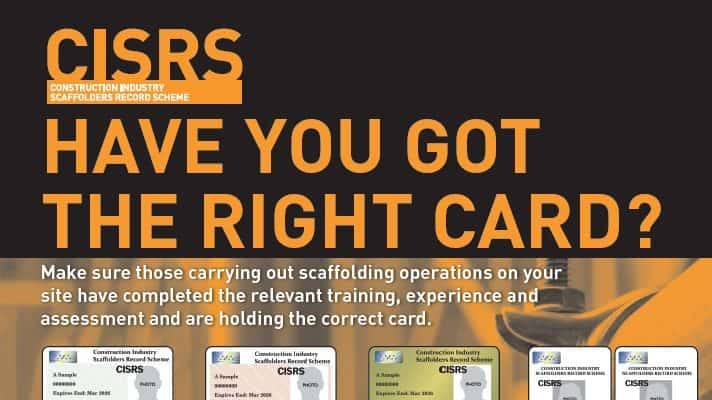

Dave Mosley said “This project is about sharing best practice. All countries must abide by international regulations and directives, however there is a huge difference in how strictly these are applied and how individual countries or sectors infer competence when it comes to Scaffold Inspection.

“Several UEG members have existing programmes in place. If we can use these to help us set a minimum standard that all members can work towards, it will have a massively positive effect.”

Robin James added “UK plays a prominent role in UEG, and collaboration with our European partners has proved beneficial for the UK scaffolding industry over the years. The NASC is widely-respected for the quality and range of its scaffolding guidance, and CISRS is regarded as the benchmark for industry training across Europe”.

Dave Mosley said “This project is about sharing best practice. All countries must abide by international regulations and directives, however there is a huge difference in how strictly these are applied and how individual countries or sectors infer competence when it comes to Scaffold Inspection.

“Several UEG members have existing programmes in place. If we can use these to help us set a minimum standard that all members can work towards, it will have a massively positive effect.”

Robin James added “UK plays a prominent role in UEG, and collaboration with our European partners has proved beneficial for the UK scaffolding industry over the years. The NASC is widely-respected for the quality and range of its scaffolding guidance, and CISRS is regarded as the benchmark for industry training across Europe”.

The 2-day event concluded with a guided tour around the Training Centre and Safety Parc just outside Arlanda Airport in Stockholm.

The 2-day event concluded with a guided tour around the Training Centre and Safety Parc just outside Arlanda Airport in Stockholm.

Danny Dwyer, Managing Director of PHD Access, said: “We are immensely proud to have won this prestigious contract to create the access structure that will allow conservation work to be carried out on HMS Victory.

“One of our great strengths is being able to create specifically designed access solutions for difficult or unusual projects. This is one reason why we have created a good reputation when it comes to working with heritage projects which often have their own unique challenges that need to be successfully overcome.

“A key requirement for this project was to create a viable access solution that not only allowed the specialists to carrying out the conservation work but that also allowed the public to have a close-up view of the renovation at the same time.

It is an honour to think we will have played our part in helping to preserve this important piece of history.”

Professor Dominic Tweddle, Director General of The National Museum of the Royal Navy said: “After ten hard years exhaustively studying HMS Victory from bowsprit to beetles (yes really) and then designing and fitting a new high-tech support system, the next stage of the works begins. ?

Victory will be partly covered to allow rotten wood to be painstakingly removed and replaced. ?And the brilliant thing is that our visitors will be able to get close up and personal with the ship and see the works close up under the guidance of our expert ship wrights!!”

Andrew Baines, Project Director for HMS Victory explained: “Conservation work on HMS Victory steps up a gear now as we enter a hugely significant phase that will temporarily transform her and open up an incredibly exciting opportunity to see her in a new light and interpret her story in a way never done before.

“We need to construct access scaffold, inside the temporary building, to allow our shipwrights and conservators access to the rotten hull planking in order to remove it. Once removed, we must then let what’s left dry out, before we can then make repairs and then re-plank with new timber.”

“The decade-long project will ensure the ship is protected for the next half century, as the ship’s rotten outer shell is removed and replaced with new oak. Repairs will be made to the ship’s structural framework and she will be fully re-rigged, in a process lasting ten to fifteen years and costing £35 million.

Victory’s ceremonial function as flagship of the First Sea Lord will continue and the white ensign will still be flown from the ensign staff.”

Danny Dwyer, Managing Director of PHD Access, said: “We are immensely proud to have won this prestigious contract to create the access structure that will allow conservation work to be carried out on HMS Victory.

“One of our great strengths is being able to create specifically designed access solutions for difficult or unusual projects. This is one reason why we have created a good reputation when it comes to working with heritage projects which often have their own unique challenges that need to be successfully overcome.

“A key requirement for this project was to create a viable access solution that not only allowed the specialists to carrying out the conservation work but that also allowed the public to have a close-up view of the renovation at the same time.

It is an honour to think we will have played our part in helping to preserve this important piece of history.”

Professor Dominic Tweddle, Director General of The National Museum of the Royal Navy said: “After ten hard years exhaustively studying HMS Victory from bowsprit to beetles (yes really) and then designing and fitting a new high-tech support system, the next stage of the works begins. ?

Victory will be partly covered to allow rotten wood to be painstakingly removed and replaced. ?And the brilliant thing is that our visitors will be able to get close up and personal with the ship and see the works close up under the guidance of our expert ship wrights!!”

Andrew Baines, Project Director for HMS Victory explained: “Conservation work on HMS Victory steps up a gear now as we enter a hugely significant phase that will temporarily transform her and open up an incredibly exciting opportunity to see her in a new light and interpret her story in a way never done before.

“We need to construct access scaffold, inside the temporary building, to allow our shipwrights and conservators access to the rotten hull planking in order to remove it. Once removed, we must then let what’s left dry out, before we can then make repairs and then re-plank with new timber.”

“The decade-long project will ensure the ship is protected for the next half century, as the ship’s rotten outer shell is removed and replaced with new oak. Repairs will be made to the ship’s structural framework and she will be fully re-rigged, in a process lasting ten to fifteen years and costing £35 million.

Victory’s ceremonial function as flagship of the First Sea Lord will continue and the white ensign will still be flown from the ensign staff.”

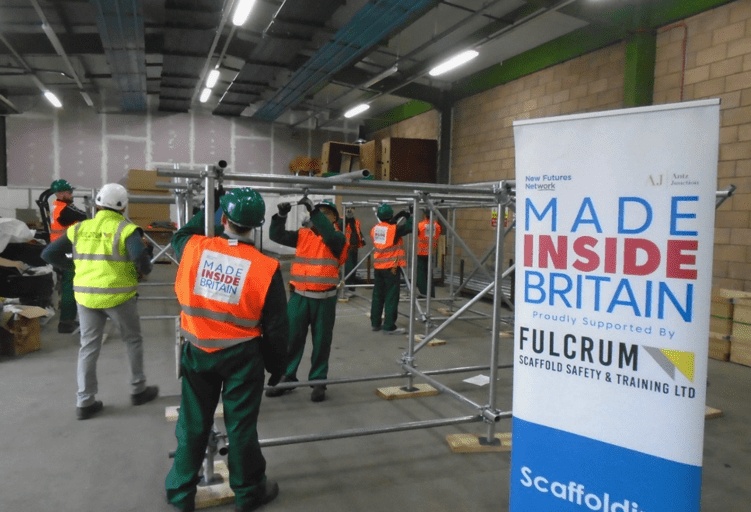

Henry Annafi added: “It’s amazing how much interest in the scaffolding industry there was from visitors at Catterick. The fact that there was such a surge of interest in applications demonstrates that our message is getting out there to the wider Forces community.

“Ultimately though, it’s all down to the energy, enthusiasm and participation of our members, who each offer their time to promote careers within our sector, with no guarantee of reward. It’s always a privilege to work alongside them.”

Henry Annafi added: “It’s amazing how much interest in the scaffolding industry there was from visitors at Catterick. The fact that there was such a surge of interest in applications demonstrates that our message is getting out there to the wider Forces community.

“Ultimately though, it’s all down to the energy, enthusiasm and participation of our members, who each offer their time to promote careers within our sector, with no guarantee of reward. It’s always a privilege to work alongside them.”

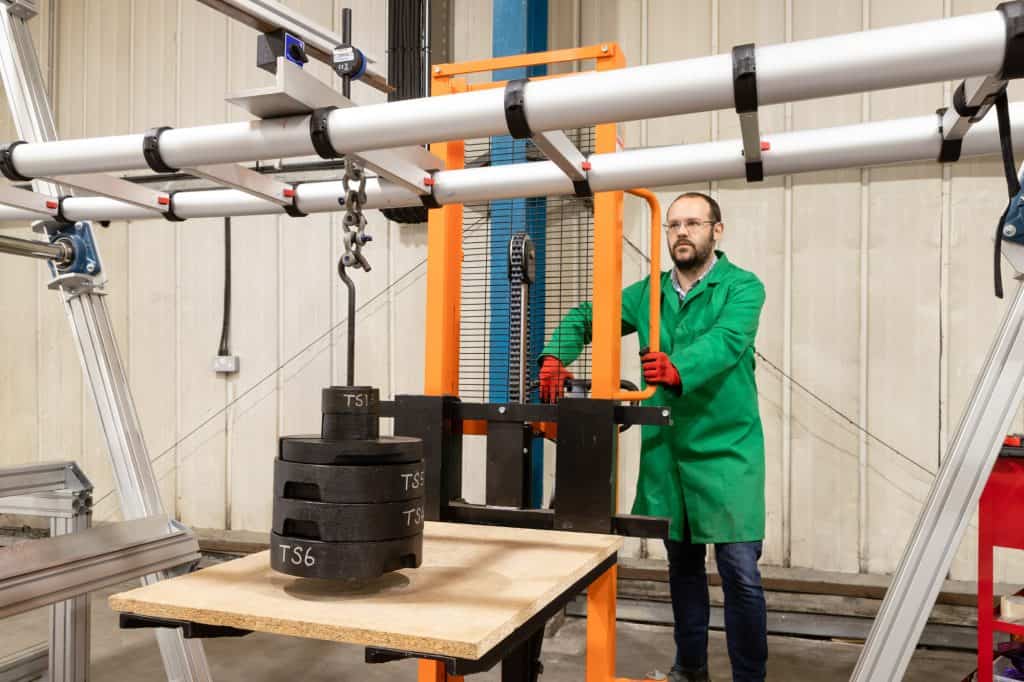

Peter Bennett OBE, Executive Director of the Ladder Association, commented: “Making sure consumers are safe is our number one priority and we are committed to raising awareness of potentially harmful ladders. We are aware of below-standard ladders being sold across the UK to unsuspecting customers, and we are particularly surprised and unsettled to hear that some of our best-loved retailers are stocking potentially hazardous products.

“The evidence we have found of unsafe ladders being retailed in the UK is astounding. The majority of telescopic ladders we tested did not meet the minimum safety requirements designed to keep users safe. These ladders are dangerous and have the potential to cause serious injury. Retailers have a legal and moral duty to consumer safety, and it is vital that they carry out due diligence to ensure that products are safe, particularly when they have been imported to the UK from an unknown manufacturer. We hope our research conducted in partnership with Trading Standards and Suffolk County Council gives both consumers and retailers an increased awareness around the issue and encourages them to exercise caution when sourcing ladders.”

Vicki Burch, Chair of the East of England Trading Standards Association Product Safety Group, said: “EETSA and Suffolk Trading Standards Imports Team have found it invaluable to work with the Ladder Association on this project. From the samples provided by EETSA, over half failed the appropriate tests to the applicable safety standard. For those telescopic ladders identified as non-compliant to EN 131-6, action has been taken to ensure they are removed from sale. EETSA would advise consumers to take time to research before buying, particularly online, buy from reputable sources and check product reviews. If consumers have concerns about the safety of a product before or after purchase, it should be reported to Trading Standards.”

Gail Hounslea, Chair of the Ladder Association, added: “Our research carried out in the Telescopic Ladder Surveillance Survey underlines the importance of putting safety first when it comes to purchasing ladders. It’s easy to assume that ladders being sold from a recognisable site or store are ‘trustworthy’ and these marketplaces would only sell tried and tested products, but sadly this is not always the case. We are calling on consumers to shop safer, and one way to guarantee product safety is to buy from a Ladder Association member. We are also urging suppliers, retailers and importers to play their role in sourcing only compliant and safe ladders. If they are unsure of the quality, they should have them independently tested within the UK. No matter their size, retailers and suppliers must take greater responsibility for consumer safety.”

The Ladder Association and East of England Trading Standards Association are committed to ensuring customer safety through testing and product recommendations. Following the results of the Survey, both organisations are calling for increased vigilance of the issues on the part of suppliers, marketplaces and social media selling platforms, as well as enforcement agencies and governing bodies, and a joined-up approach with Trading Standards to stop these products at port.

Founded in 1947 and celebrating its 75th anniversary this year, the Ladder Association is the voice of the industry and promotes the highest standards and competence, while working with major bodies including the Health & Safety Executive. The Association harnesses its own expertise along with that of its member companies to support technical excellence, safety and best practice in the interests of ladder users everywhere. All Ladder Association members are required to make or supply ladders that meet the current product standard.

To find out more information on the Step Up to Safe Ladders campaign and to view the full report, please follow the link:

Peter Bennett OBE, Executive Director of the Ladder Association, commented: “Making sure consumers are safe is our number one priority and we are committed to raising awareness of potentially harmful ladders. We are aware of below-standard ladders being sold across the UK to unsuspecting customers, and we are particularly surprised and unsettled to hear that some of our best-loved retailers are stocking potentially hazardous products.

“The evidence we have found of unsafe ladders being retailed in the UK is astounding. The majority of telescopic ladders we tested did not meet the minimum safety requirements designed to keep users safe. These ladders are dangerous and have the potential to cause serious injury. Retailers have a legal and moral duty to consumer safety, and it is vital that they carry out due diligence to ensure that products are safe, particularly when they have been imported to the UK from an unknown manufacturer. We hope our research conducted in partnership with Trading Standards and Suffolk County Council gives both consumers and retailers an increased awareness around the issue and encourages them to exercise caution when sourcing ladders.”

Vicki Burch, Chair of the East of England Trading Standards Association Product Safety Group, said: “EETSA and Suffolk Trading Standards Imports Team have found it invaluable to work with the Ladder Association on this project. From the samples provided by EETSA, over half failed the appropriate tests to the applicable safety standard. For those telescopic ladders identified as non-compliant to EN 131-6, action has been taken to ensure they are removed from sale. EETSA would advise consumers to take time to research before buying, particularly online, buy from reputable sources and check product reviews. If consumers have concerns about the safety of a product before or after purchase, it should be reported to Trading Standards.”

Gail Hounslea, Chair of the Ladder Association, added: “Our research carried out in the Telescopic Ladder Surveillance Survey underlines the importance of putting safety first when it comes to purchasing ladders. It’s easy to assume that ladders being sold from a recognisable site or store are ‘trustworthy’ and these marketplaces would only sell tried and tested products, but sadly this is not always the case. We are calling on consumers to shop safer, and one way to guarantee product safety is to buy from a Ladder Association member. We are also urging suppliers, retailers and importers to play their role in sourcing only compliant and safe ladders. If they are unsure of the quality, they should have them independently tested within the UK. No matter their size, retailers and suppliers must take greater responsibility for consumer safety.”

The Ladder Association and East of England Trading Standards Association are committed to ensuring customer safety through testing and product recommendations. Following the results of the Survey, both organisations are calling for increased vigilance of the issues on the part of suppliers, marketplaces and social media selling platforms, as well as enforcement agencies and governing bodies, and a joined-up approach with Trading Standards to stop these products at port.

Founded in 1947 and celebrating its 75th anniversary this year, the Ladder Association is the voice of the industry and promotes the highest standards and competence, while working with major bodies including the Health & Safety Executive. The Association harnesses its own expertise along with that of its member companies to support technical excellence, safety and best practice in the interests of ladder users everywhere. All Ladder Association members are required to make or supply ladders that meet the current product standard.

To find out more information on the Step Up to Safe Ladders campaign and to view the full report, please follow the link: