A construction company and scaffolding firm will have to pay a combined $230,000 as part of a settlement agreement with New Zealand’s Health & Safety Board WorkSafe.

The substantial fine comes after an on-site incident in 2018 which resulted in injuries to a painting contractor who fell 3.5 meters from scaffolding. Main contractor Stevenson and Williams and Bramwell Scaffolding are set to pay a combined $230,000 with $40,000 going to the victim. An investigation found that during work on a 15 three-storey residential apartments, lead contractor Stevenson and Williams contracted Bramwell Scaffolding to supply and erect scaffolding and roof edge protection.The painting contractor was applying primer to various balcony decks and during the work leaned on a handrail which gave way, resulting in the fall and various injuries.

The contractor wasn’t able to work for four weeks as a result of the injuries.

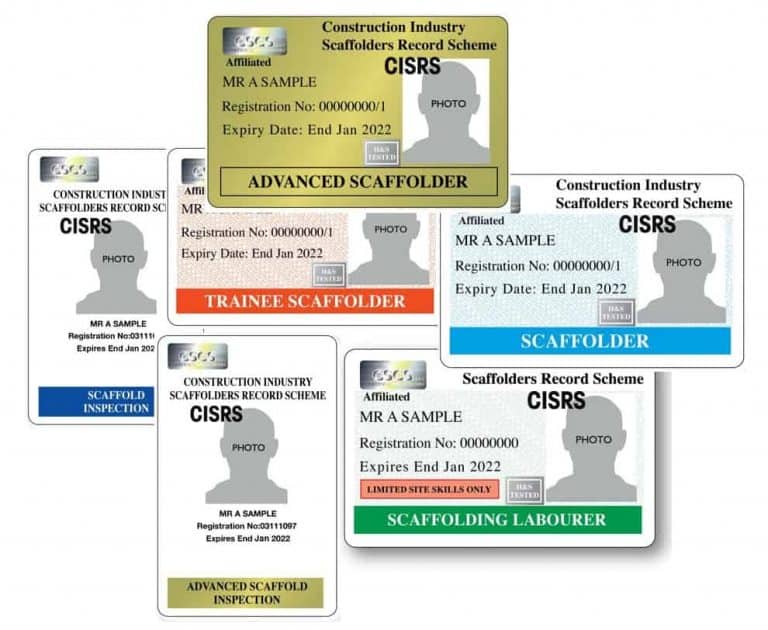

Subsequent investigation determined that the certified scaffolder on-site had left the site for personal reasons and that scaffolding erection had been left to a labourer.

No qualified inspection had been done following that work.

Stevenson and Williams managing director Rob Cunningham told the Otago Daily Times the company had been ”devastated” by the incident and the injury.

He said he had immediately visited the site to determine what had gone wrong and had also seen the worker.

‘‘He is back at work now and we are just happy that it didn’t turn out any worse.

”We are absolutely committed to taking all the steps necessary, putting the necessary systems and process in place to make sure it doesn’t happen again,”

Cunningham said the company had long prided itself on its attention to safety and systems.

”This is a low point for us and we fully intend to learn from the unfortunate circumstance around it.”

Cunningham said while there had obviously been a problem with the scaffolding in this instance, Bramwell remained as a preferred contractor and was definitely one of the ”best in the business”.

Since these buildings are often visited by tourists, it’s important they maintain their characteristic visual aesthetic, so the scaffold wraps cover up any unsightly scaffolding, making it almost invisible.

Since these buildings are often visited by tourists, it’s important they maintain their characteristic visual aesthetic, so the scaffold wraps cover up any unsightly scaffolding, making it almost invisible.

He founded PPM in 2011 after leaving the print company he had started at age 19 and run for 18 years, deciding to become a specialist large-format creative print coordinator.

He founded PPM in 2011 after leaving the print company he had started at age 19 and run for 18 years, deciding to become a specialist large-format creative print coordinator.