NASC appoints new in-house Marketing Manager

The NASC has bolstered their team and strengthened its communications capabilities through the appointment of a new in-house marketing manager.

New Marketing Manager, Simon Robinson brings a wealth of construction marketing and copywriting expertise to the NASC team, the 34-year-old has previously held various marketing agency and news desk positions in his career.

The confederation says their new Marketing Manager will work to strengthen ties and increase engagement with both NASC members and the wider construction industry.

Robinson said: “I am delighted to join the NASC and am looking forward to developing and implementing a communications strategy that will help increase awareness of the Confederation’s primary objectives; to help our members grow safer businesses and contribute to a safer construction industry.”

Robin James, NASC Managing Director, added: “I am pleased to welcome Simon to the team. Through his appointment, we will be able to engage more closely with our 250+ members and communicate more effectively with the wider scaffolding and construction industries.”

This will enable us to increase understanding and appreciation of a number of key messages, including the various benefits available directly to businesses through attaining NASC membership or indirectly through utilising the services of NASC members, as well as our ongoing commitment to raising and maintaining the highest standards for access and scaffolding throughout the UK and beyond.”

Record growth reported by Altrad

The Altrad group has reported strong growth in revenue and earnings from the Group’s expanded and diversified platform for the last fiscal half year.

Up to February 28th, they achieved record group revenue of €1,678 million with a full half-year contribution from Cape Altrad. A successful strategic focus on services contributed to 82 percent of turnover. Their Integration of the Cape business is progressing well and delivering expected synergies.Positive Figures

Impressive earnings before interest, taxes, depreciation and amortization (EBITDA) of €205million – a margin of 12 percent, offers a popular indicator of the company’s financial performance. The management expects to deliver a sustainably higher EBITDA margin going forward. Other highlights include a total backlog of €2,782 million providing good visibility on future revenue and diversification of geographic revenue with more than 30 percent coming out of Europe. Altrad has consolidated its position as a multi-disciplinary, industrial leader in key markets around the world, with a focus on Europe, Australia, Middle East, Africa and Asia.Securing Contracts

During the period, the Group was pleased to secure a number of material contracts, including an offshore maintenance contract in Angola awarded by BP for more than €30 million over three years and £25 million annual maintenance contracts, across the Grangemouth petrochemical facility in the UK. The strategic focus on Services provides strong visibility on future revenue, with more than 70 percent of the Group’s reported services revenue coming from recurring maintenance contracts.Setting Down A Marker

Commenting on the Results, CEO Louis Huetz said: “These results showcase the strength and breadth of our expanded business, highlighting the considerable progress we have made along our strategic growth path in the last few years. Our business is underpinned by strong cash flow and profitability, and our strategic focus on Services now provides good visibility on future revenue, with a secured order book of nearly €3 billion for delivery over the next few years.” The completion of the Cape acquisition has enabled the creation of a stronger and more balanced business, capable of delivering multi-disciplinary services to industry leaders throughout our chosen markets. The organic growth opportunities for the business remain compelling as we leverage our industry-leading platform to achieve better synergies, and demonstrate to our client base the benefits of our greater geographic footprint and diversified services.”

Catalyst For Success

In effect, the acquisition of Cape represents a truly transformative catalyst for the Altrad Group and continues the strategic development achieved by the acquisitions of Prezioso Linjebygg and Hertel in previous years. This delivery of record revenue and earnings surpasses internal budgets and supports the Group’s Full Year expectations. Such an outstanding performance was achieved within the first six-month contribution of the Cape business. The near-term outlook for the Group is positive, underpinned by improving market conditions in core sectors and geographies. Their strong order book comprises of diverse, recurring maintenance services contracts. Altrad’s business is now underpinned by diverse and steady revenue streams, from an international footprint and a balanced sales mix between its core sectors: Construction, Oil & Gas, Process Industries and Power Generation. During the period, the construction market has seen a recovery in activity, especially in continental Europe. As a result, the equipment business has seen an improved like-for-like performance, and the Group won a number of key services contracts including in France, where the Group was selected for the renovation of the Austerlitz railway station. This award follows the successful work delivered on Bordeaux Railway station last year, leaving Altrad well placed to benefit from the broader renovation program of the main French railway stations. Other key contract awards included the Acetylene project for BASF, a greenfield development of a new plant and the second largest project for German chemicals industry over the last decade.Looking Forward

Altrad’s strategic objectives remain to build a worldwide leader in industrial services, with market leading positions in key geographies and a diverse range of services.ScaffMag Issue 2 goes live

Our Spring 2018 Digital Issue has been published.

Following on from our successful launch issue back in the winter of 2017 – that was seen by more than 11,000 industry personnel, we now have the pleasure of letting you know our free Spring issue is now available to read and download now.

Click Here To Read Now

What’s inside this issue?

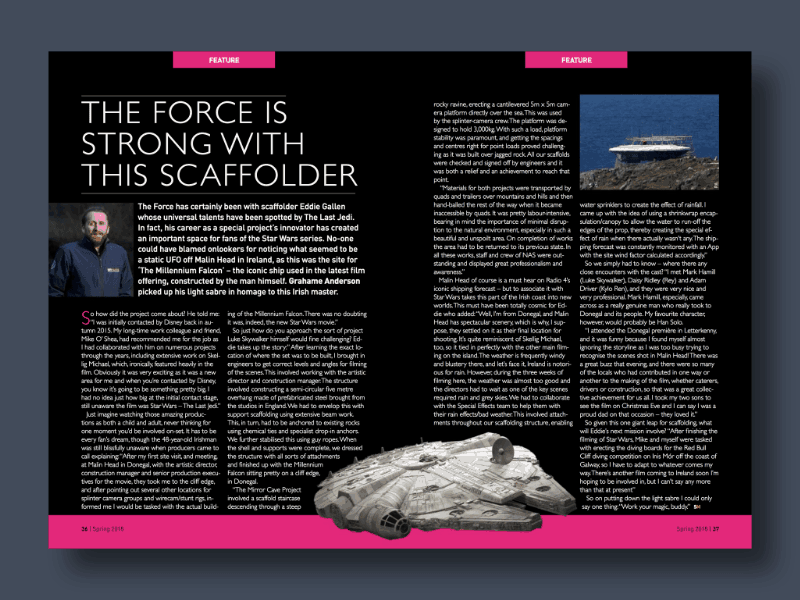

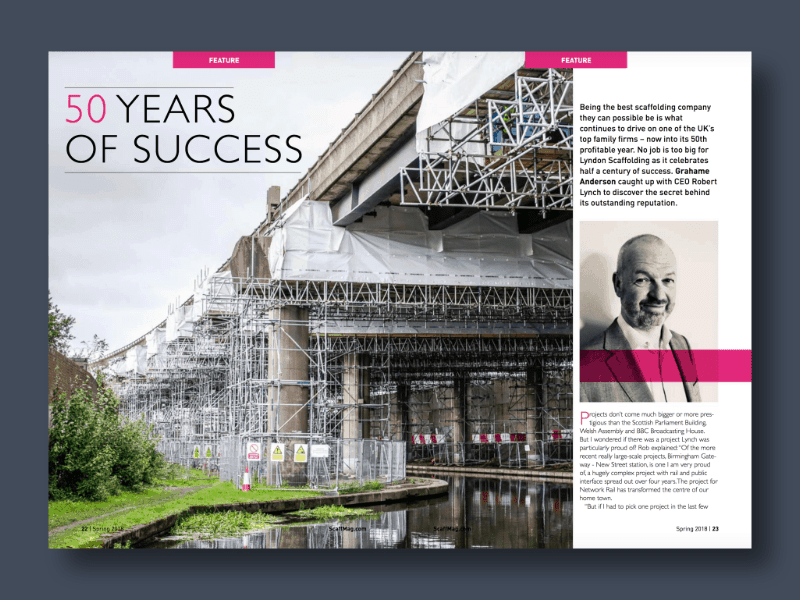

Packed into this 52 paged exciting issue of ScaffMag’s digital magazine offering features an exclusive interview with Lyndon Scaffolding’s CEO Rob Lynch as the firm turns 50 years-old. Additionally, we find out how the legendary firm that is SGB are well and truly back in business after reverting back to their well-known brand. We also speak to the Starwars scaffolder Eddie Gallen as he tells us what it was like to build the scaffold for the Millennium Falcon in the box office hit film ‘The Last Jedi’.

We also speak to the Starwars scaffolder Eddie Gallen as he tells us what it was like to build the scaffold for the Millennium Falcon in the box office hit film ‘The Last Jedi’.

Click Here To Read Now

The Regulars

Returning to this issue is our regular sections covering the latest industry news roundup, in our Opinion section Robin James from the NASC contributes by giving his perspective on the collapse of Carillion. And we find out that change is coming with the aid of Virtual Reality in our Innovations section. Plus much more. Happy reading!Submit News / Advertise In The Next Issue

Got some interesting industry news you would like to be featured in our next issue? Or do you have a product or service you want to showcase to thousands of industry eyeballs? We have a variety of advertising spaces available in our next issue. Drop us an Email »Wood awarded five year contract with Lucite International

Industrial services provider Wood has been awarded a new five-year contract by Lucite International UK Ltd.

Wood will be providing industrial services at the Cassel site in Billingham, Teesside, UK. Onshore fabrication, steelwork, electrical and rigging support services will be deployed under the new contract, which is effective immediately and includes a two-year extension option. Cassel is the largest methyl methacrylate (MMA) facility in Lucite International’s portfolio. It has been manufacturing chemicals at Billingham since 1930 with an annual capacity of 250 kilo-tonnes per year (kte). Dave Stewart, CEO of Wood’s Asset Solutions business in Europe, Africa, Asia & Australia, said: “This long-term contract builds on our relationship with Lucite International, developed following our recent work to support the refurbishment of the Cassel site. “We look forward to leveraging our broad industrial service capabilities to successfully deliver this contract, which further strengthens Wood’s onshore footprint within the chemical and manufacturing sector in the UK.”Tower crane drops pallet of bricks on pedestrian

A woman is fighting for her life after being hit by a pallet of bricks dropped from a tower crane.

The 28-year-old victim was passing a Higgins Homes construction site in east London yesterday morning when the crane dropped its load. According to reports, the Police in Tower Hamlets are appealing for witnesses after launching an investigation with the Health and Safety Executive. A police statement said: “Officers were called at 09:38hrs on Tuesday, 27 March to Burdett Road at the junction with St Pauls Way, E3. “A 28-year-old woman had apparently been struck by debris falling from a building site crane. “The London Ambulance Service attended and the woman was taken to an east London hospital, where she remains in a critical condition.”GKR develop new ‘Saddle’ scaffolding fitting

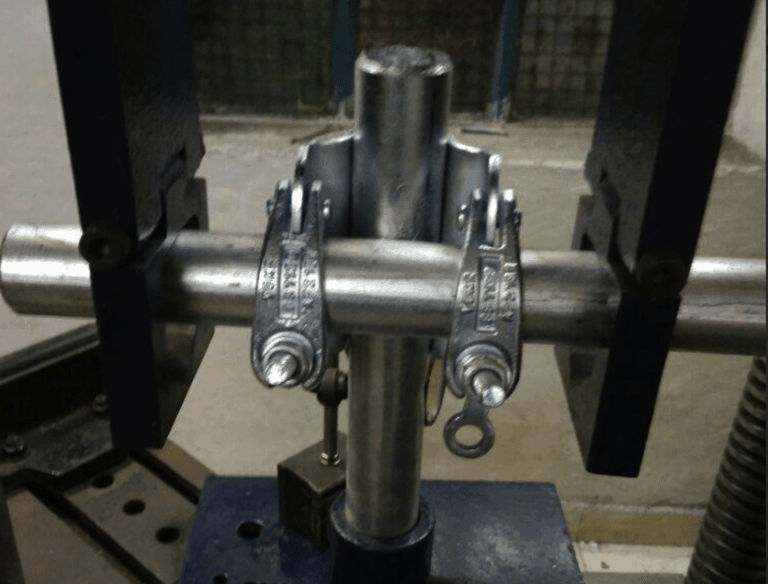

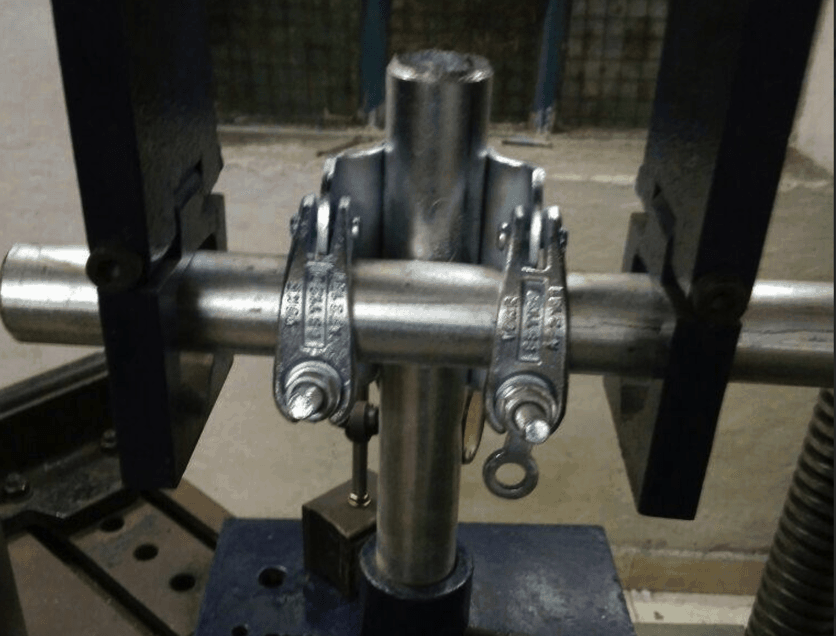

GKR Scaffolding is in the final weeks of testing and is soon to introduce a new multi-use fitting.

The new patent fitting called the “Saddle™” will be for the use with tube and fittings and system scaffolds. Group Director Lee Roswell at GKR Scaffolding broke the news on Linkedin late last week. Working in partnership with VR Access and Loughton Plant, Lee Roswell said: “The ‘Saddle™” has been developed as a multi-use fitting, having numerous applications for all scaffolding applications.” Uses with the Saddle™ fitting to include:- A replacement to the structural (Aberdeen) transom (final testings by end of March 2018)

- One piece tie to be used with drilled anchors

- Guardrail puncheons

- Loading bearing birdcages

- Loading bearing scaffolds

- Gantry Scaffolds

- Loading Bays

- Temporary roofs

- Sheeted and debris netted scaffolds for flush outside finish.

- Guardrails without protruding bolts

At first glance, the ‘Saddle™’ coupler looks like it’s taken inspiration from a band and plate fitting and the shape of a couple of singles. GKR have confirmed the new fitting has a 9.1 kN capacity equal to an EN74-1-B Double Coupler.

GKR Scaffolding is no stranger to creating new revolutionary scaffold fittings after the success of their Elimin8 tethered fitting back in 2014.

This new product has taken GKR 18 months from concept to the final weeks of testing.

More to follow..

At first glance, the ‘Saddle™’ coupler looks like it’s taken inspiration from a band and plate fitting and the shape of a couple of singles. GKR have confirmed the new fitting has a 9.1 kN capacity equal to an EN74-1-B Double Coupler.

GKR Scaffolding is no stranger to creating new revolutionary scaffold fittings after the success of their Elimin8 tethered fitting back in 2014.

This new product has taken GKR 18 months from concept to the final weeks of testing.

More to follow.. Scaffolding Manager jailed for fraud

A scaffolding company manager has been jailed for stealing money from his own firm to fund a chronic gambling addiction.

Daniel Bell, 45, received a sentence of two-and-a-half years at Basildon Crown Court after admitting stealing £326,000 between June 2015 and July 2016. Working in his role as commercial manager for Durston Scaffolding Ltd based at Laindon, Bell was caught following an attempt to destroy documentation covering financial discrepancies at the company. He had previously falsified invoices so he could divert the cash straight into his own bank account in order to carry on his addiction.Repercussions For The Company

The actions of the former betting shop manager resulted in the company being forced into voluntary liquidation, also causing great embarrassment to the reputation of its owner and director. Paul Durston discovered holes in the accounts after returning from holiday. He confronted Bell, from Alburgh in Norfolk with facts, recording the conversation. Bell, who is married with a 13-year-old son then admitted committing fraud. Mr.Durston who is rebuilding his life has since managed to set up a new company called Durston Scaffolding Ltd, based in Canvey but with offices in London Road, Westcliff.Long-Term Problem

The court was told Bell had been addicted to gambling since he was a teenager as his mother had been in a relationship with a bookmaker. His own attempt at managing his own bookmaking shop proved to be unsustainable.

A Serious Sentence

On passing sentence, Judge Owen-Jones said: “I cannot ignore that, although no charges were brought, you had done exactly the same thing some years before and were given a second chance.” “You were dismissed for gross misconduct and the company was forced into voluntary liquidation, causing massive embarrassment and damaged Mr. Durston’s personal reputation.” “He went through hell as a result of this – there’s no doubt about it. His house is up on the market in order to manage his debt and he has sustained stress and depression.” GamCare operates the National Gambling HelpLine, and remains the first port of call for anyone experiencing problems with gambling.Bilfinger wins multi-million pound contract with Shell

Industrial services specialist Bilfinger Salamis UK has been awarded a multimillion-pound contract for technical manpower services on Shell U.K. southern North Sea (SNS) assets.

The three-year contract covers the execution of maintenance operations services onshore at Bacton Gas Plant, and offshore on the Leman Alpha Platform, Clipper and Seafox 4 Barge as well as the Kroonborg Walk-to-Work vessel supporting NAM in the Dutch sector. Bilfinger Salamis UK’s Managing Director, Sandy Bonner, commented: “We are delighted to have secured this contract as it further solidifies our position as a leading provider of Modifications, Maintenance and Operations (MMO) services. “Bilfinger has worked extensively with Shell and NAM for many years. Shell’s decision to award this contract to us is testament to the strong, collaborative relationship we have.” Over 150 personnel will transfer to Bilfinger Salamis UK from the incumbent contractor, in electrical, mechanical, pipe fitting, welding, crane and rigging disciplines. In January alone, Bilfinger recruited and rehired over 600 personnel in the UK, positioning the firm as a leading employer in the sector.Investment in Southern North Sea

The contract will be managed from Bilfinger’s Great Yarmouth base. The company is a major player in the SNS, having had a presence in the region since 1981. Initially focused on offshore fabric maintenance, the company has since expanded its SNS and Netherlands offering, and in recent years developed its service capability to secure maintenance, inspection and renewables contracts. Key customers including Statoil, ConocoPhillips, Perenco and Oranje Nassau Energie (ONE) UK.

Malvern set to start work on Birmingham’s tallest residential tower

Malvern Scaffolding has been awarded the prestigious scaffolding package on the Left Bank Tower 2 project in Birmingham.

Positioned on one of Birmingham city centre’s busiest street the tower will become the city’s tallest residential building. Once complete the Left Bank project will provide 206 one, two and three-bed apartments, internal and external residential amenity space and a commercial retail unit. Worcestershire based Malvern Scaffolding will be providing a variety of access and scaffold solutions on all elevations and floors.

Speaking to ScaffMag Jon Stone, Commercial Director at Malvern Scaffolding said: “It’s great to have secured another new project with Wates. We’ve had a very positive experience with the Project team on a £30million Retirement village that is now coming to a close, and the opportunity to continue the relationship is beneficial for all.”

Malvern’s first task on site is some fairly extensive design work to facilitate the installation of Mastclimbers says Stone. “Pedestrian access needs to be maintained around the site on the West elevation, so we are building a 30 m long gantry that will support the entire working load of the Mastclimbers for the full height (100m+) of the building.”

The firm next month will erect scaffolding to the other elevations and works to the various floors will be implemented as the building rises.

Malvern Scaffolding anticipates being on site until Summer 2019.

“This is one of a number of high profile jobs secured so far in Q1 and helps us maintain our strategy of working on a diverse portfolio of works for leading Main Contractors and Blue Chip companies. We currently have works in hand with the likes of Amey, Balfour Beatty, Bouygues, Clugston, GSK, Heineken, Kier, Speller Metcalfe, Willmott Dixon” Stone added.

Worcestershire based Malvern Scaffolding will be providing a variety of access and scaffold solutions on all elevations and floors.

Speaking to ScaffMag Jon Stone, Commercial Director at Malvern Scaffolding said: “It’s great to have secured another new project with Wates. We’ve had a very positive experience with the Project team on a £30million Retirement village that is now coming to a close, and the opportunity to continue the relationship is beneficial for all.”

Malvern’s first task on site is some fairly extensive design work to facilitate the installation of Mastclimbers says Stone. “Pedestrian access needs to be maintained around the site on the West elevation, so we are building a 30 m long gantry that will support the entire working load of the Mastclimbers for the full height (100m+) of the building.”

The firm next month will erect scaffolding to the other elevations and works to the various floors will be implemented as the building rises.

Malvern Scaffolding anticipates being on site until Summer 2019.

“This is one of a number of high profile jobs secured so far in Q1 and helps us maintain our strategy of working on a diverse portfolio of works for leading Main Contractors and Blue Chip companies. We currently have works in hand with the likes of Amey, Balfour Beatty, Bouygues, Clugston, GSK, Heineken, Kier, Speller Metcalfe, Willmott Dixon” Stone added.

First female completes Overseas Scaffolder Training

Female Safety Officer becomes the first woman to attend and complete CISRS Overseas Scaffolder Training.

CISRS have announced that Miss Hien Pham, a Safety Officer with Black Cat JSC Ltd has successfully completed both OSTS Level 1 Scaffolder and Basic Scaffold Inspection courses at the AIS/Blackcat CISRS approved Training centre located in Vang Tau, Vietnam. Miss Pham becomes the first female to attend CISRS Overseas scaffolder training, the overseas scheme is hoping that she will be the first of many. CISRS say, the level one course includes both theoretical and practical sessions, covering general health and safety, working at height guidance, prevention of fall from heights, component recognition, understanding basic drawings, safe methods of erection and dismantle of basic structures such as towers and independent scaffolds. Miss Pham said: “The first time I went on site and witnessed scaffolding operations taking place I realised I wanted to learn more about how these structures where constructed. Participating in the Level 1 course has highlighted to me, the correct way to build scaffolding. I think the information on fall protection and avoiding falls from height is especially important for everyone involved in the sector.” “The Inspection course is essential to me as a safety officer, it has given me a lot more in-depth knowledge of scaffolding and will help me to spot hazards, either with defective equipment or poor construction and allow me to identify corrective actions.” “I am really happy and proud to have completed these two courses.” Miss Pham said. The partnership with North East Training Provider AIS and Blackcat JSC Ltd gained CISRS OSTS accreditation in October 2017 with the aim of upskilling and improving the competencies of its own employees, as well as servicing the training requirements of the lucrative Indo-China oil and gas and construction markets.

David John Adams Lead Instructor for AIS training said: “Blackcat has invested a huge amount into the development of scaffolding training and safety in Vietnam and AIS will continue to help them achieve that aim.”

“It’s great to see CISRS OSTS promotes equality and diversity, both AIS and Blackcat are committed to delivering high-quality training to all, within the region and worldwide.”

“The drive and dedication of Mr Ho Kha the Chairman of Blackcat JSC to improve the levels of Scaffolding safety and competence and of his employees are evident from the quality of centre he has established and the training programme he has put in place.”

Mr. Kha added: “Hien is the first female scaffolder in Vietnam, her passion and commitment to the industry is fantastic, she is a highly valued member of the Blackcat team. We will continue to invest in the whole of our workforce for the benefit of our organisation and our client base.”

The partnership with North East Training Provider AIS and Blackcat JSC Ltd gained CISRS OSTS accreditation in October 2017 with the aim of upskilling and improving the competencies of its own employees, as well as servicing the training requirements of the lucrative Indo-China oil and gas and construction markets.

David John Adams Lead Instructor for AIS training said: “Blackcat has invested a huge amount into the development of scaffolding training and safety in Vietnam and AIS will continue to help them achieve that aim.”

“It’s great to see CISRS OSTS promotes equality and diversity, both AIS and Blackcat are committed to delivering high-quality training to all, within the region and worldwide.”

“The drive and dedication of Mr Ho Kha the Chairman of Blackcat JSC to improve the levels of Scaffolding safety and competence and of his employees are evident from the quality of centre he has established and the training programme he has put in place.”

Mr. Kha added: “Hien is the first female scaffolder in Vietnam, her passion and commitment to the industry is fantastic, she is a highly valued member of the Blackcat team. We will continue to invest in the whole of our workforce for the benefit of our organisation and our client base.”