SGB Scaffolding is back on the scene after the announcement of a huge £13 million four-year deal with Countryside.

The once legendary industry giant SGB has today revealed details to ScaffMag on this significant new deal. The scaffold contract sees SGB appointed as the sole scaffolding provider to Countryside’s North West division. SGB which is part of the Brand Energy & Infrastructure Services group will now provide scaffolding services to Countryside.

SGB say the negotiations were led by SGB’s Business Development Manager, Jason Milner. “We are extremely proud and excited to be partnering Countryside on these schemes,” he said. “We currently have 23 live sites in progress with more set to follow, and this will make a great contribution to our planned growth strategy over the next 4 years.”

The Countryside work will be focussed on SGB’s Manchester depot, where General Manager Alan Arthur added: “We have proved to Countryside the we have the size, strength and capabilities that few other scaffolding providers, if any, can match, but which are essential to fulfil a major contract such as this.”

SGB has told us they already have a well-established relationship with Countryside. In 2014 the company was chosen from a list of five scaffolding suppliers to be Countryside’s sole provider, under a two-year deal, which saw the volume of business grow to an annual order value of £3.5m

“This new deal is a result of all the hard work and commitment from the team in Manchester, with particular praise going to our site teams led by Operations Manager John Woodcock,” adds Jason Milner. “John and his teams have delivered some 3,400 units of scaffolding over the last five years, successfully meeting challenging build programs in a very fast-paced environment.”

SGB is now working with Countryside to extend the contract model to other areas of the UK. It has already secured contracts covering two new sites developed by Countryside’s Midlands office, with more set to follow.

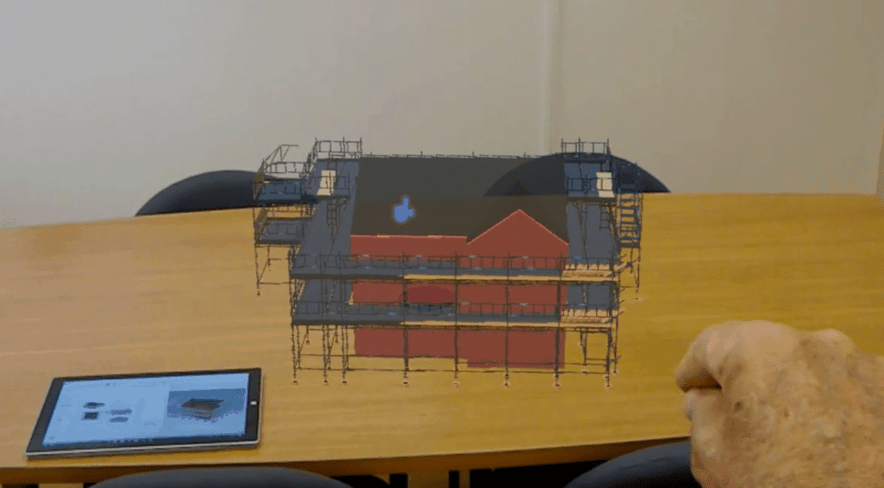

An innovative approach to construction has resulted in a new and unique revolutionary Lynch scaffolding system. Working in combination with tube and fitting scaffolds, it’s been designed to meet all access requirements, saving valuable time on the whole process.

An innovative approach to construction has resulted in a new and unique revolutionary Lynch scaffolding system. Working in combination with tube and fitting scaffolds, it’s been designed to meet all access requirements, saving valuable time on the whole process.

The announcement was made during the gala awards ceremony at the Derby Velodrome on Thursday 9th November. The Rilmac Group (comprising of Insulation, Asbestos Services, Fabrication and Scaffolding divisions) were also shortlisted to be a finalist in the prestigious Family Business of the Year Award.

Paul Walker, Group Chairman and, second generation family member said, “there is a lot of hard work in putting together applications, creating suitable presentations, and preparing for the challenging interviews. Whilst only a smaller team was responsible for the award entry, it is the effort and dedication of everyone at Rilmac Scaffolding that has been rewarded with the Highly Commended recognition.”

Steve Baxter, Group MD, added. “This is a team endeavor and every employee at Rilmac Scaffolding has played a part in achieving this success. Thank you to everyone for their positive involvement. It is wonderful to see everyone’s hard work recognised in this way.”

“As a Lincolnshire based business it was great to see how many fellow companies from the county had also been shortlisted this year. The event further outlined how successful and buoyant the Family Business community is across the Midlands. Every entry was of a very high standard and there were some fantastic business success stories told.”

The Awards were expertly managed by The Wilson Group and included shortlisted finalists from as far afield as Worcester and Skegness.

The announcement was made during the gala awards ceremony at the Derby Velodrome on Thursday 9th November. The Rilmac Group (comprising of Insulation, Asbestos Services, Fabrication and Scaffolding divisions) were also shortlisted to be a finalist in the prestigious Family Business of the Year Award.

Paul Walker, Group Chairman and, second generation family member said, “there is a lot of hard work in putting together applications, creating suitable presentations, and preparing for the challenging interviews. Whilst only a smaller team was responsible for the award entry, it is the effort and dedication of everyone at Rilmac Scaffolding that has been rewarded with the Highly Commended recognition.”

Steve Baxter, Group MD, added. “This is a team endeavor and every employee at Rilmac Scaffolding has played a part in achieving this success. Thank you to everyone for their positive involvement. It is wonderful to see everyone’s hard work recognised in this way.”

“As a Lincolnshire based business it was great to see how many fellow companies from the county had also been shortlisted this year. The event further outlined how successful and buoyant the Family Business community is across the Midlands. Every entry was of a very high standard and there were some fantastic business success stories told.”

The Awards were expertly managed by The Wilson Group and included shortlisted finalists from as far afield as Worcester and Skegness.

Now in it’s fourteenth year, the Construction News Specialist Awards celebrates the outstanding achievements of the very best specialist contractors in the UK.

Topping the list is the Access & Scaffolding Specialist Category that has been shortlisted to just eight companies.

Now in it’s fourteenth year, the Construction News Specialist Awards celebrates the outstanding achievements of the very best specialist contractors in the UK.

Topping the list is the Access & Scaffolding Specialist Category that has been shortlisted to just eight companies.

To bring this incredible Grade I listed building back to its wonder it took over 4 years. The bulk of the project comprised of the removal and replacement of all of the original glass panes, as well as repair and maintenance of the steel frame. Working over such a long time frame meant that our client would be working all year round, whatever the weather. The Generation UNI Roof meant that work could continue all year and kept the project to its time-scales come rain or shine.

The equipment formed three different structures. The most technically challenging being the 8000m2 all season Temporary Roof system; the UNI Roof spanned 50m over the central glasshouse. The roofing showcased its compatibility, versatility, weather protection and safe and quick erection; showing how the Generation UNI Roof is so much more than just a Temporary Roofing structure. The customer knew that such a large and important job needed the help of the company that supply’s the market leader in Temporary Roofing; The Generation UNI Roof.

Generation Frimley worked closely with their client to provide over 700 tons of equipment, this was delivered directly to the site of Kew gardens using Generations large and reliable fleet.

Interested in finding out more about the

To bring this incredible Grade I listed building back to its wonder it took over 4 years. The bulk of the project comprised of the removal and replacement of all of the original glass panes, as well as repair and maintenance of the steel frame. Working over such a long time frame meant that our client would be working all year round, whatever the weather. The Generation UNI Roof meant that work could continue all year and kept the project to its time-scales come rain or shine.

The equipment formed three different structures. The most technically challenging being the 8000m2 all season Temporary Roof system; the UNI Roof spanned 50m over the central glasshouse. The roofing showcased its compatibility, versatility, weather protection and safe and quick erection; showing how the Generation UNI Roof is so much more than just a Temporary Roofing structure. The customer knew that such a large and important job needed the help of the company that supply’s the market leader in Temporary Roofing; The Generation UNI Roof.

Generation Frimley worked closely with their client to provide over 700 tons of equipment, this was delivered directly to the site of Kew gardens using Generations large and reliable fleet.

Interested in finding out more about the