Beaver 84 Selects Avontus’ Scaffold Designer Software to Visualize and Design Scaffolding Projects

The leading scaffold supplier Beaver 84 will use Scaffold Designer to plan projects that require Plettac Contur system scaffolding.

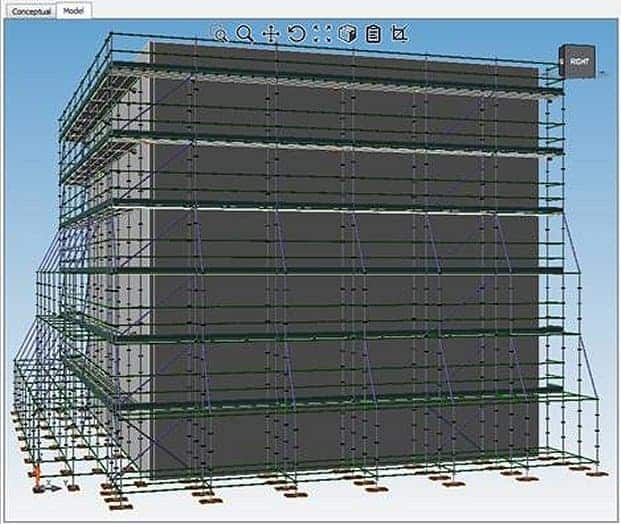

Following an extensive search of available scaffolding design tools, Beaver 84 has selected Avontus’ Scaffold Designer as its recommended software. With its 3D visualization, drag-and-drop design capabilities, and automatic materials calculation, Scaffold Designer takes the guesswork out of system scaffolding design. Beaver 84, a leading UK scaffold supplier, plans to roll out Scaffold Designer to each of its 9 depots in the coming weeks, and will make trials of the easy-to-use software available to its clients.

“We chose Scaffold Designer because it supports our Plettac Contur system scaffolding and it allows us and our customers to design scaffolding exactly the way it will be built,” commented David Hughes, National Sales Manager of Beaver 84. “Avontus clearly understands scaffolding, and Scaffold Designer is developed to meet, and even exceed, the needs we and our customers have,” he continued.

Whilst Scaffold Designer automatically supports Plettac Contur system scaffolding, Avontus will customize the software for Beaver 84 to support its other scaffold systems, giving Beaver 84’s customers access to its full range of system scaffolding options.

Implementing Scaffold Designer will help Beaver 84 and its customers increase safety, order and allocate materials more efficiently, increase the use of system scaffolding, and provide superior service to their customers.

“We are looking forward to continuing to build our relationship with Beaver 84 as system scaffolding becomes more prevalent in the UK scaffolding market,” added Andrew Smith, Director of Sales of Avontus. “The combination of superior scaffold materials and powerful scaffold software will give Beaver 84 and its customers a significant competitive edge.”

About Avontus

Avontus has been producing quality software since 1995, both custom development for enterprises and packaged software for the general public. With a focus on the user experience, our software for the formwork, scaffolding, and shoring industries is the best in the industry. Our employees are highly skilled computer and business professionals who understand big-picture problem solving, team project management, and the latest technology. Avontus Software also owns and maintains web portals and web services for falsework (scaffold, shoring, and formwork) professionals. For more information, visit http://avontus.com/.

About Beaver 84

Since formation in 1984 Beaver84 has established itself as a dedicated supplier of non-mechanical construction equipment for both Hire and Sales. The strategy is supported by an understanding of investment and innovation and the need to maintain the service and Quality across all aspects of the business. Over many years Beaver 84 has continued to offer a unique and specialist product range from site set up, excavation, construction through to completion by working in partnership with its clientele. For more information, visit http://www.beaver84.co.uk.

of available scaffolding design tools, Beaver 84 has selected Avontus’ Scaffold Designer as its recommended software. With its 3D visualization, drag-and-drop design capabilities, and automatic materials calculation, Scaffold Designer takes the guesswork out of system scaffolding design. Beaver 84, a leading UK scaffold supplier, plans to roll out Scaffold Designer to each of its 9 depots in the coming weeks, and will make trials of the easy-to-use software available to its clients.

“We chose Scaffold Designer because it supports our Plettac Contur system scaffolding and it allows us and our customers to design scaffolding exactly the way it will be built,” commented David Hughes, National Sales Manager of Beaver 84. “Avontus clearly understands scaffolding, and Scaffold Designer is developed to meet, and even exceed, the needs we and our customers have,” he continued.

Whilst Scaffold Designer automatically supports Plettac Contur system scaffolding, Avontus will customize the software for Beaver 84 to support its other scaffold systems, giving Beaver 84’s customers access to its full range of system scaffolding options.

Implementing Scaffold Designer will help Beaver 84 and its customers increase safety, order and allocate materials more efficiently, increase the use of system scaffolding, and provide superior service to their customers.

“We are looking forward to continuing to build our relationship with Beaver 84 as system scaffolding becomes more prevalent in the UK scaffolding market,” added Andrew Smith, Director of Sales of Avontus. “The combination of superior scaffold materials and powerful scaffold software will give Beaver 84 and its customers a significant competitive edge.”

About Avontus

Avontus has been producing quality software since 1995, both custom development for enterprises and packaged software for the general public. With a focus on the user experience, our software for the formwork, scaffolding, and shoring industries is the best in the industry. Our employees are highly skilled computer and business professionals who understand big-picture problem solving, team project management, and the latest technology. Avontus Software also owns and maintains web portals and web services for falsework (scaffold, shoring, and formwork) professionals. For more information, visit http://avontus.com/.

About Beaver 84

Since formation in 1984 Beaver84 has established itself as a dedicated supplier of non-mechanical construction equipment for both Hire and Sales. The strategy is supported by an understanding of investment and innovation and the need to maintain the service and Quality across all aspects of the business. Over many years Beaver 84 has continued to offer a unique and specialist product range from site set up, excavation, construction through to completion by working in partnership with its clientele. For more information, visit http://www.beaver84.co.uk. TRAD Hire & Sales receives great reviews and feedback at Barking open day

TRAD Hire & Sales receives great reviews and feedback from both clients and end users at their recent open day in Barking.

It was only in April of this year that TRAD Hire & Sales, the UK’s leading Scaffold Supplier, celebrated opening their National Training and Product Awareness Centre in Barking, and is now leading the way with an ongoing series of open days across the country. Having successfully hosted two previous open days in East London and Leeds during 2015, the Scaffold Specialists returned to their new Training Centre on the 4th November to showcase two of the markets most innovated products – Metrix and Altrix, both of which are unique to TRAD Hire and Sales in the UK. The demonstration of the Plettac Metrix System Scaffold and the showcasing of the new ALTRIX Temporary Roof system were met with extremely positive reviews from some of the UK’s leading Construction Companies and Scaffolding Contractors. The event kicked off with an introduction to the New National Training facilities followed by a demonstration of the unique Plettac METRIX System Scaffold, proven to be significantly faster to erect than all other ring based systems but even more so compared to traditional Tube & Fittings. A time-lapse video demonstrated both the speed and benefits of METRIX, comparing it against conventional tube & fittings and two other well- known ring-based systems. The comparative speed and ease of use of METRIX conclusively proved the system to be superior in every respect and the time lapse video was enthusiastically received by all those attending. Construction industry experts are hailing Metrix as revolutionary, quoting labour savings benefits, programme time reductions, and the systems versatility as its key attributes. The introduction of the optional Permanent Advance Guardrail also improves safety as they are installed from the safety of the lift below. Attendees were then introduced to TRAD’s newest product, ALTRIX; an all-aluminium temporary roofing and weather protection system, Alan Slater, TRAD Group Technical Support Manager explained how the roofing system has been designed to work with any scaffold and complements the METRIX system perfectly. Manufactured using fast Push-Fit technology with colour-coded components to allow for easy identification and speedier assembly times (all as the colour coding of the Metrix System), ALTRIX uses far less components than other roofing systems which significantly reduces the costs of purchasing, storage and transportation. An additional benefit of the system is the ability to install the roof sheets from the safety of the scaffold platform. With the Open Day well underway, TRAD Group Managing Director, Des Moore reviewed the real-world benefits of the METRIX and ALTRIX systems. Following the event, he said: ‘The product launch at our National Training Centre was met with positivity across the board. I firmly believe that these two products are the very best on the market today and that our industry will greatly benefit from their time and labour cost saving capabilities.” The open day then concluded with an insightful Presentation from Des, who as well as being responsible for the three TRAD Group Companies, has extensive experience in Scaffolding Contracting, having previously been the Managing Director of TRAD Scaffolding for some fifteen years and having used System Scaffolding for the past twenty five years. A very robust Q&A session followed with Des that covered a wide range of topics, including TRAD’s Business model and the real commercial benefits that can be gained along with the essential Management approach that is required by any user wishing to extract the full benefits of using both METRIX and ALTRIX. Attendees were highly complementary of TRAD’s product demonstrations and many expressed their eagerness to start using the products straight away. Andrew Millington, Managing Director of Jubilee Scaffolding in Jersey was very impressed by the safety and practical working benefits of the products: “I currently use the cuplock system, but I think Plettac METRIX will be twice as quick to erect and dismantle. The safety is fantastic – working from underneath rather than on top, with the guardrail system in place, and being able to work to SG4:15 all the times. For all the benefits it gives me, I would definitely use Plettac METRIX in the future. Edmond Carolan, Director of ENJ Scaffolding in Essex, shared his views: “Plettac METRIX is a very impressive piece of kit, especially with the ALTRIX roof… The best part for me is the labour saving – instead of 4:2 ratio of four scaffolders to two labourers, you could have four labourers to two scaffolders. That’s a big saving. It would be interesting to bring some of the lads to one of TRAD’s live jobs to get their thoughts on how investing in Plettac METRIX – and eventually replacing Cuplock – could benefit the business.” Des Moore concluded that for the first time in the UK there is a ‘Very Real’ alternative to the previously well-known supplier of ring based system scaffolding. We believe that the ALTRAD Group has a much better offering to the market in every respect, from Design, Supply and Customer Support, coupled with TRAD`s nationwide Hire and Sales distribution, and in-house knowledge sharing from a Group that can advise its clients how to get the very best from the System because it has that experience that no other Suppliers can offer. Over and above that we believe the Products just speak for themselves. Come and see for yourself at one of our Open Days. To be among the first to experience the cost saving benefits of TRAD Hire & Sales’ new products, book your place on one of our upcoming open days – places are limited so book now to be a part of the scaffolding revolution on 0161 494 2999 or email [email protected].Bilfinger gains £100M Scottish terminals contract renewal with BP

Bilfinger gains £100 million three-year maintenance contract renewal with BP securing more than 240 jobs in Scotland.

Under the agreement the German firm will provide maintenance services at two of its oil and gas terminals, the Forties Pipeline System at Grangemouth and Sullom Voe Terminal, Shetland. The three-year contract covers services such as scaffolding, rope access, insulation, blast cleaning, painting and fire-proofing and will be delivered by Bilfinger’s industrial services division. News of the huge contract came as BP’s rival Shell revealed that its multi-billion pound deal to buy oil and gas firm BG Group is set to lead to some 2,800 job losses. Bilfinger said the contract with BP will involve more than 240 employees, with many based permanently on-site at the BP facilities. Around 24 of the roles will be apprenticeship or trainee positions. Bilfinger’s industrial services is one of two Bilfinger UK businesses to have existing agreements with BP, alongside its electrical engineering division. The two groups have worked together in the UK for more than six years. Duncan Hall, executive president of Bilfinger Oil & Gas, said: “BP is a long-term strategic partner for Bilfinger and we support them across their upstream and midstream assets. We have been delivering these specialist and critical areas of plant maintenance across these key UK assets since 2010. “This latest agreement is a landmark for Bilfinger in the UK which further cements our position as a leading support services provider to the energy sector. Two-thirds of all diesel and petrol sold in the UK comes from production assets that we help maintain.”Firm in court after scaffolding blown over during dismantling

A Leicestershire scaffolding company has been fined after scaffolding hit a bus and pedestrians when it blew over during dismantling.

Leicester Magistrates’ Court heard how on 28 January 2015 Emperor Scaffolding Limited of Leicester was dismantling scaffolding on Charles Street when the incident occurred. The scaffolding hit a bus, landed on a parked van and hit two members of the public. See original news report: Pedestrian Trapped After Scaffolding Collapses In Leicester An investigation by the Health and Safety Executive (HSE) into the incident, found that the company was not following a safe system of work. The scaffolding was not tied to the building and sheeting was left in place. The scaffolding dismantling took place over four days and the workers failed to check the scaffolding condition before they started or to take adequate measures to correct defects and ensure it would not collapse during the dismantling. Emperor Scaffolding Limited, of Fairefield Crescent, Glenfield, Leicester, was fined a total of £8,000, with costs of £2,000 after pleading guilty to offences under Regulation 28(1) of the Construction (Design and Management) Regulations. Speaking after the hearing HSE inspector Martin Giles said: “Scaffolding needs to be tied to a building and dismantling needs to be properly planned and carried out in a safe manner.”Wind brings down scaffolding onto parked cars

High winds are thought to of caused a 40-meter run of scaffolding to topple onto parked cars in North Staffordshire.

SIX vehicles are thought to have been damaged after scaffolding tumbled onto them yesterday morning. The incident in Loggerheads occurred as North Staffordshire continues to be battered by high winds. Firefighters were called out to Co-op on Eccleshall Road at about 9.40am following reports of a 40-metre long scaffold falling down. The crews noted that it had fallen on six vehicles parked close to the shop. It was dismantled and the area was made safe. They left the scene just after 2pm.NASC Launches SG4:15

At a packed AGM in Leeds the NASC last night launched eagerly awaited SG4:15 ‘Preventing Falls in Scaffolding Operations’ guidance.

As previously mentioned, many of the principles of SG4 remain unchanged in this update, however SG4:15 provides more guidance on systems of work and available equipment to help comply. SG4:15 also contains several new areas of guidance that have been included to reflect the availability of new innovations and changes to recognised ‘good practice’

The new additions include guidance on:

- Chimney scaffolds

- Bridging with beams

- Floor height lifts

- Cantilever scaffolds

- New PFPE (Personal Fall Protection Equipment)

- Loading bay gate installation

Scaffolder is prosecuted after Roofer falls to his death

A Castleford scaffolder has been prosecuted after a worker fell to his death from a roof.

Walter Booth (trading as WB Roofing) was carrying out repairs to the roof of Micklegate Methodist Church, Pontefract on 3 September 2012. A Health and Safety Executive (HSE) investigation found the scaffolding edge protection provided by Mr Wayne Morgan (trading as Barnsdale Scaffolding) failed to follow the profile of the roof edge leaving a gap through which 63 year old Mr Booth fell. Wayne Morgan of Barnsdale Estate, Cutsyke, Castleford, pleaded guilty to breaching Regulation 8(a) of the Work at Height Regulations 2005, and was sentenced to 200 hours unpaid work and ordered to pay £15,000 in costs by Wakefield Magistrates Court. After the hearing, HSE inspector Sarah Lee commented: “This was an entirely preventable death. In this case the scaffolding edge protection was not sufficient to prevent a person falling from the roof. The scaffold installation should have been erected correctly, follow the profile of the roof and have no large gaps. The standards for scaffold are well known and have been in place for many years. It is vital that scaffolders ensure that scaffold is erected as per the standards and it is checked after it is erected, to ensure that everything is in place.”NASC publishes updated guidance notes

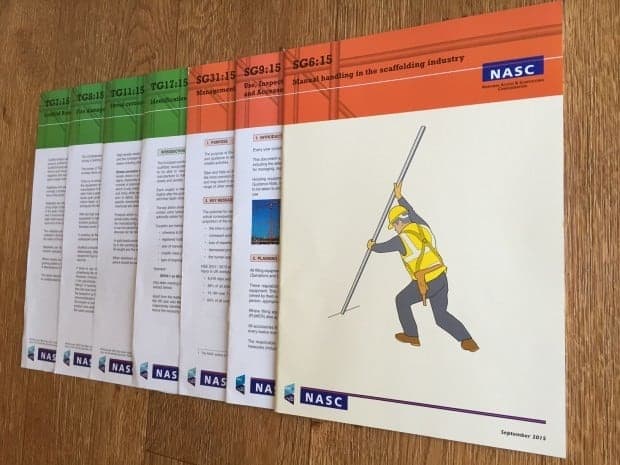

The NASC has released a raft of seven revised and updated Technical Guidance (TG) and Safety Guidance (SG).

The revisions come as part of the NASC’s on-going commitment to refresh published technical and safety guidance on a five year cycle. NASC members have already received copies of seven guidance notes in the post during November 2015 these will also be available to full members via download, free of charge, via the NASC website. A full list of the updated guidance and what’s included as follows:- SG6:15 – Manual Handling in the Scaffolding Industry: A well-established document that remains robust and valid (date changes only).

- SG9:15 – Use, Inspection & Maintenance of Lifting Equipment and Accessories for Lifting in Scaffolding: A complete review with new visuals.

- SG31:15 – Management of Slips and Trips: Significant changes including added images.

- TG7:15 – Scaffold Board Nailplates: Date changes only.

- TG8:15 – Fire Damage: Cost of fire damage evaluation does not warrant recovery of metal components.

- TG11:15 – Stress Corrosion Cracking in High Tensile and Alloy Steels: Minor amendments only including change of date.

- TG17:15 – Identification of EN74-1 Couplers: Date changes only.