Altrad to Acquire Norwegian Industrial Firm

Altrad, a global leader in industrial services, has announced a voluntary cash offer to acquire all outstanding shares of Beerenberg AS, a prominent Norwegian provider of maintenance and modification services.

This strategic move aligns with Altrad’s ongoing efforts to expand its global footprint and enhance service offerings across various sectors. The transaction, expected to close by the end of 2024, is contingent upon receiving regulatory approvals and meeting other customary conditions. Altrad’s Co-CEO, Ran Oren, expressed enthusiasm about the potential acquisition, highlighting Beerenberg’s strong management team and impressive industry track record. “We have admired Beerenberg from a distance for many years and have been impressed by the achievements of the management team and their talented people,” said Oren. “Our objective is to build on this success by adding investment, skilled people, innovative products, and a broader range of services to support their clients’ ambitions.” Beerenberg, headquartered in Bergen, Norway, has been a key player in the maintenance and modification services sector for 47 years, particularly within the Norwegian Continental Shelf. The company also operates internationally, providing insulating products and a range of services throughout the petroleum industry’s lifecycle. The acquisition will bring Beerenberg’s 2,350 employees into the Altrad Group, where they will be integrated into Altrad’s extensive global network, which spans more than 55 countries. The move is seen as an opportunity for Beerenberg employees to further develop their careers within a larger, more diverse organization. Altrad, known for its multidisciplinary services and strong presence in the energy, power generation, oil & gas, and construction sectors, generated sales of €5.3 billion and an EBITDA of €674 million for the fiscal year ending 31 August 2023. The proposed acquisition underscores Altrad’s commitment to investing in businesses that share its vision and values, further solidifying its position as a leader in the industrial services market.Scaffolding Collapse in Cardiff Causes Major Damage at Industrial Estate

Scaffolding access and temporary edge protection at Trident Industrial Park in Cardiff collapsed on Monday, causing extensive damage to multiple vehicles parked below.

According to WalesOnline, the incident was triggered by strong winds and occurred near a gym and trampoline park, where the scaffolding was being used for ongoing construction. South Wales Fire and Rescue Service responded promptly, cordoning the area to prevent further damage and ensure public safety. Fortunately, no injuries were reported, but the businesses nearby, including the gym, experienced significant disruption. The sheeted scaffolding was part of a project to refurbish a unit within the industrial estate. Eyewitnesses described a sudden gust of wind that dislodged the scaffolding, sending it crashing down onto several cars parked outside the gym.

NASC and CISRS to Overhaul Scaffolding Training Following Eye-Opening 2024 Report

In a bold move that could reshape the scaffolding industry, the National Access & Scaffolding Confederation (NASC) has published its much-anticipated ‘Training in the Scaffolding Industry: Report 2024.’

The comprehensive report sheds light on the current state of training in the sector, revealing both opportunities and urgent areas for improvement. NASC, in partnership with the Construction Industry Scaffolders Record Scheme (CISRS), has pledged to take immediate action and use the report’s findings to drive substantial reforms. The survey, conducted earlier this year, provides an in-depth snapshot of the scaffolding industry as it stood in the first quarter of 2024. With 103 responses from 97 organisations, the report highlights significant challenges facing the sector, including nearly 2,000 job vacancies in critical scaffold roles, with Part 2 scaffolders being in the highest demand. The findings underscore the urgent need for strategic interventions to address these workforce shortages and regional disparities in training accessibility. One of the most striking revelations from the survey is the varying levels of satisfaction with training courses, with larger companies generally expressing higher contentment. However, a consistent theme among respondents was the call for enriched course content, particularly in leadership skills and mental health awareness. Additionally, the need for more immediate and constructive feedback from training providers was a recurring concern, underscoring the demand for a more responsive and dynamic training environment.“The membership has spoken, and NASC is listening.”NASC’s Training and Education Committee is set to take these insights seriously, aiming to close the gaps identified in the training landscape. The organisation has expressed gratitude to the survey participants and is committed to translating these findings into actionable strategies to future-proof the scaffolding industry.

Scaffolding Brilliance: How Allied Access and BDS Helped Revive Blackburn’s Victoria Building

Nestled in the heart of Blackburn, the Victoria Building stands as a grand testament to the town’s rich history. Built in 1888, this Grade II listed structure has witnessed over a century of change, and now, it faces one of its most significant transformations yet.

A team of experts from Allied Access and Buckley Design Solutions (BDS) are spearheading this ambitious, multi-million-pound restoration of Blackburn College’s Victoria Building. Their ingenuity and dedication are breathing new life into this historic landmark.

The Victoria Building’s red-brick facade and ornate details have long been symbols of Blackburn’s architectural heritage. However, time has taken its toll, and the building now requires meticulous internal and external restoration to preserve its structural integrity and aesthetic beauty.

This project, managed by construction giants Bam Construction Ltd., isn’t just about renovation; it’s about respecting and maintaining the historical essence of an irreplaceable piece of Blackburn’s identity.

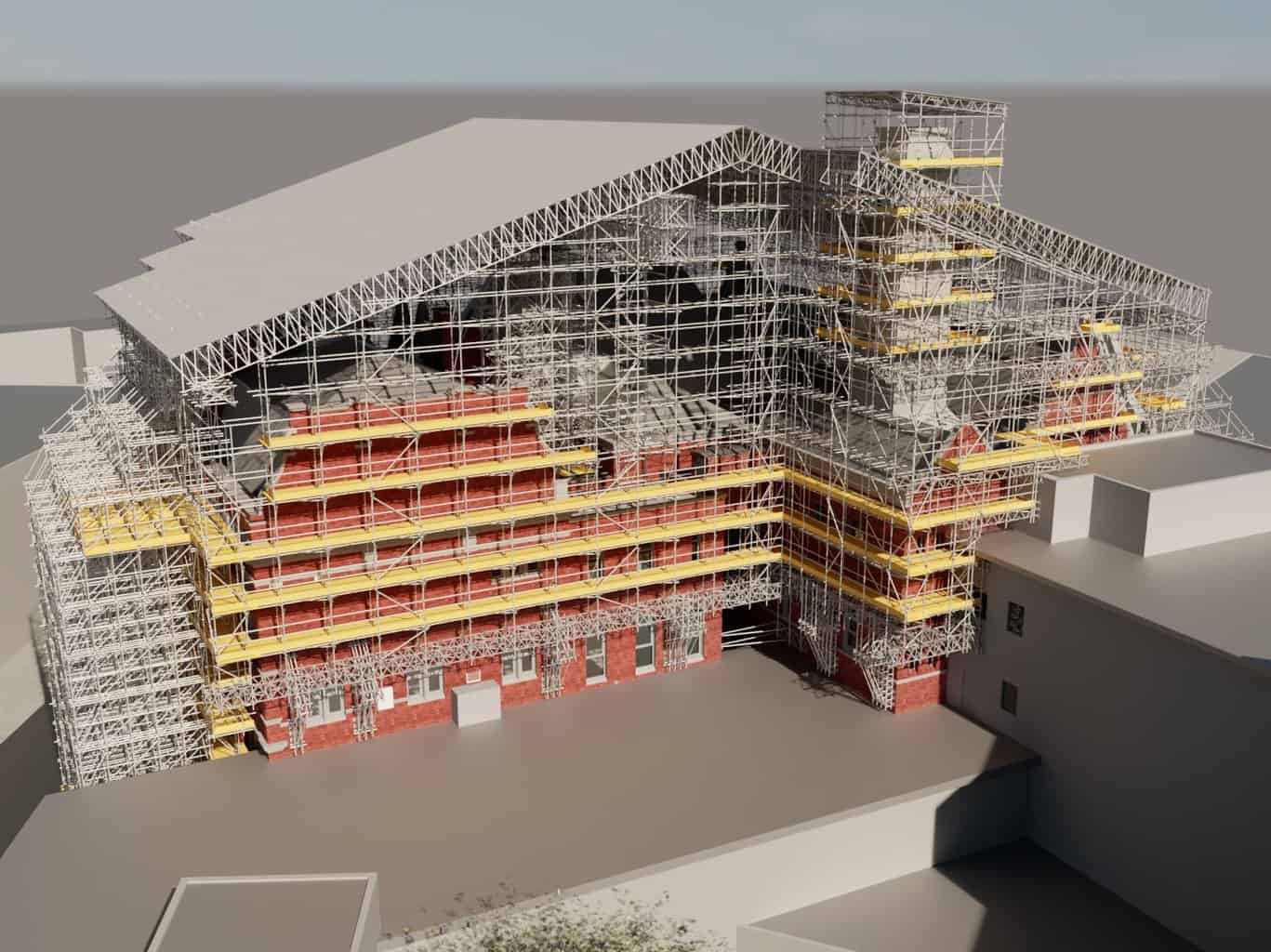

To shield the building and workers from Blackburn’s unpredictable weather, highly skilled scaffolders from Allied installed a comprehensive temporary roof. Spanning 44 meters and supported by a central spine beam through the North light well, this roof protects and enables continuous restoration work.

To shield the building and workers from Blackburn’s unpredictable weather, highly skilled scaffolders from Allied installed a comprehensive temporary roof. Spanning 44 meters and supported by a central spine beam through the North light well, this roof protects and enables continuous restoration work.

BDS told Scaffmag that the restoration project presented a series of complex challenges that required innovative solutions. Initial design plans were revised to address the building’s structural limitations and ensure the scaffolding’s effectiveness.

Revision A: The first significant design revision removed ties from the North, East, and South elevations, replacing them with buttresses. However, due to structural constraints, the West elevation remained fully tied and supported by bespoke cantilever brackets.

Revision B: A critical breakthrough came with introducing a central core tower in the North light well, distributing the load more effectively. This central tower, combined with spine beams running from East to West, significantly reduced external leg loads. A concrete raft foundation further facilitated load distribution, eliminating the need for additional support weights, or “kentledge.”

BDS told Scaffmag that the restoration project presented a series of complex challenges that required innovative solutions. Initial design plans were revised to address the building’s structural limitations and ensure the scaffolding’s effectiveness.

Revision A: The first significant design revision removed ties from the North, East, and South elevations, replacing them with buttresses. However, due to structural constraints, the West elevation remained fully tied and supported by bespoke cantilever brackets.

Revision B: A critical breakthrough came with introducing a central core tower in the North light well, distributing the load more effectively. This central tower, combined with spine beams running from East to West, significantly reduced external leg loads. A concrete raft foundation further facilitated load distribution, eliminating the need for additional support weights, or “kentledge.”

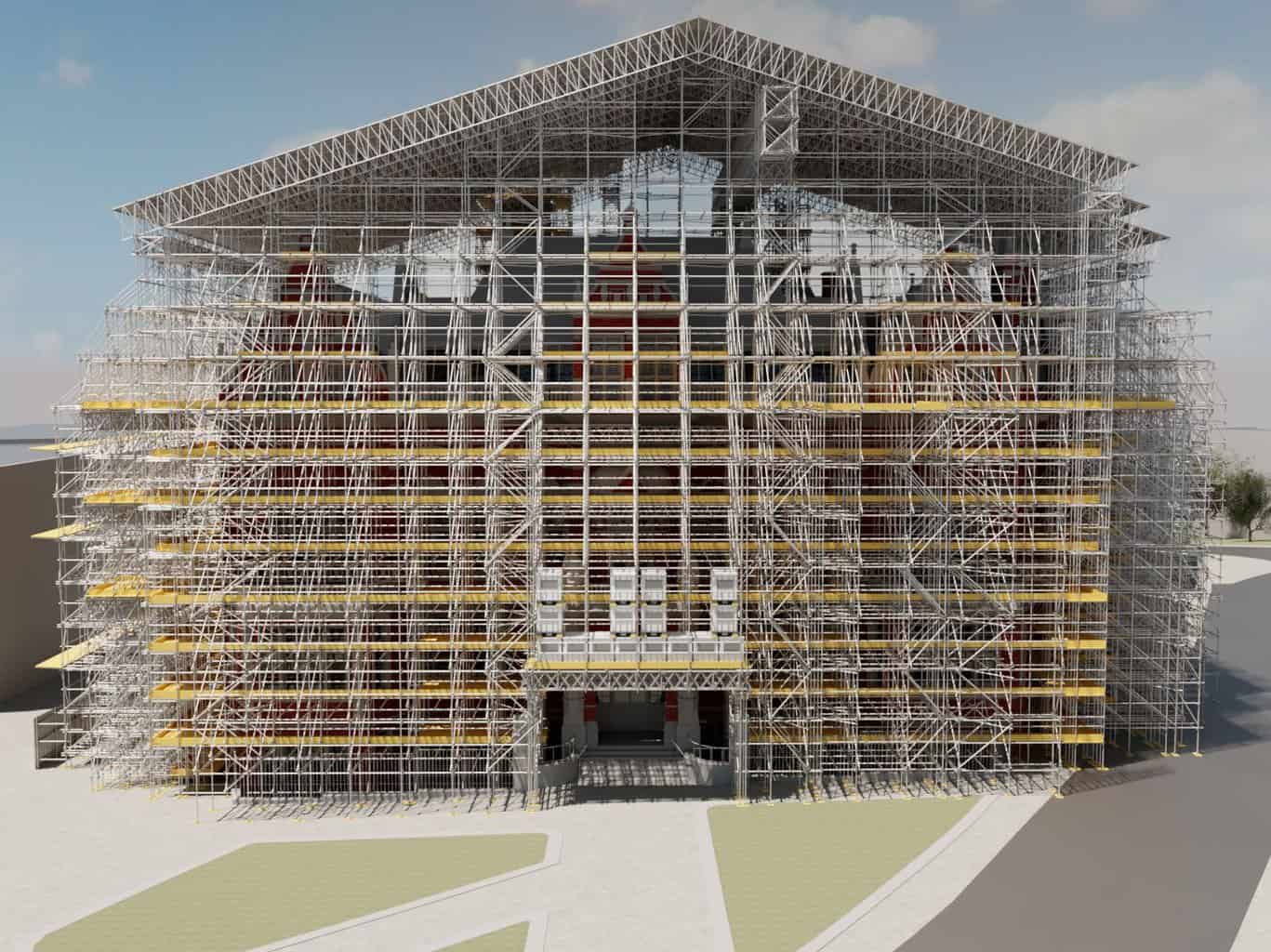

Collaboration with structural engineers from Curtins and Wentworth House Partnerships led to the development of a ring beam system, redistributing localised loads and ensuring stability. The use of 3D design models by BDS allowed the scaffolders to visualise and execute this intricate scaffolding system with precision.

Collaboration with structural engineers from Curtins and Wentworth House Partnerships led to the development of a ring beam system, redistributing localised loads and ensuring stability. The use of 3D design models by BDS allowed the scaffolders to visualise and execute this intricate scaffolding system with precision.

Key stages of the project highlighted the team’s expertise and adaptability:

Setting the Scaffolding Base: Aligning the scaffolding base correctly was paramount, considering the complex ties into the newly designed concrete raft foundation. The team’s meticulous approach ensured a stable foundation.

Cantilever Brackets Installation: Custom-designed cantilever brackets were carefully installed to support the West elevation without compromising its historical integrity.

Spine Beams Installation: Positioned with precision, the spine beams supported the temporary roof, providing a safe and effective solution for weather protection.

Temporary Roof Installation: The installation of the temporary roof ensured comprehensive coverage, allowing restoration work to proceed uninterrupted, regardless of weather conditions.

Key stages of the project highlighted the team’s expertise and adaptability:

Setting the Scaffolding Base: Aligning the scaffolding base correctly was paramount, considering the complex ties into the newly designed concrete raft foundation. The team’s meticulous approach ensured a stable foundation.

Cantilever Brackets Installation: Custom-designed cantilever brackets were carefully installed to support the West elevation without compromising its historical integrity.

Spine Beams Installation: Positioned with precision, the spine beams supported the temporary roof, providing a safe and effective solution for weather protection.

Temporary Roof Installation: The installation of the temporary roof ensured comprehensive coverage, allowing restoration work to proceed uninterrupted, regardless of weather conditions.

The Victoria Building restoration is more than a project; it’s a labour of love and a testament to the expertise and dedication of Allied Access and Buckley Design Solutions. Their innovative approach and meticulous planning have helped preserve a piece of Blackburn’s heritage and set a new benchmark for future scaffolding and restoration projects.

In reviving the Victoria Building, the team has woven a story of collaboration, innovation, and respect for history. Their work ensures that this architectural gem will continue to grace Blackburn’s skyline for generations to come.

The Victoria Building restoration is more than a project; it’s a labour of love and a testament to the expertise and dedication of Allied Access and Buckley Design Solutions. Their innovative approach and meticulous planning have helped preserve a piece of Blackburn’s heritage and set a new benchmark for future scaffolding and restoration projects.

In reviving the Victoria Building, the team has woven a story of collaboration, innovation, and respect for history. Their work ensures that this architectural gem will continue to grace Blackburn’s skyline for generations to come.

An Ingenious Scaffolding Solution

Allied Access and BDS took on the Herculean task of designing and erecting a scaffolding system that would support the restoration work while protecting the delicate structure. From the outset, it was clear that this wouldn’t be a typical scaffolding project. To avoid damaging the building’s facade, BDS designed a freestanding scaffold system for the North, East, and South elevations. This approach ensured stability without relying on the fragile walls of the historic structure. The West elevation, however, required a different strategy. Here, bespoke cantilever brackets were used due to the low load-bearing capacity of the neighboring roof.

To shield the building and workers from Blackburn’s unpredictable weather, highly skilled scaffolders from Allied installed a comprehensive temporary roof. Spanning 44 meters and supported by a central spine beam through the North light well, this roof protects and enables continuous restoration work.

To shield the building and workers from Blackburn’s unpredictable weather, highly skilled scaffolders from Allied installed a comprehensive temporary roof. Spanning 44 meters and supported by a central spine beam through the North light well, this roof protects and enables continuous restoration work.

Overcoming Design Challenges

BDS told Scaffmag that the restoration project presented a series of complex challenges that required innovative solutions. Initial design plans were revised to address the building’s structural limitations and ensure the scaffolding’s effectiveness.

Revision A: The first significant design revision removed ties from the North, East, and South elevations, replacing them with buttresses. However, due to structural constraints, the West elevation remained fully tied and supported by bespoke cantilever brackets.

Revision B: A critical breakthrough came with introducing a central core tower in the North light well, distributing the load more effectively. This central tower, combined with spine beams running from East to West, significantly reduced external leg loads. A concrete raft foundation further facilitated load distribution, eliminating the need for additional support weights, or “kentledge.”

BDS told Scaffmag that the restoration project presented a series of complex challenges that required innovative solutions. Initial design plans were revised to address the building’s structural limitations and ensure the scaffolding’s effectiveness.

Revision A: The first significant design revision removed ties from the North, East, and South elevations, replacing them with buttresses. However, due to structural constraints, the West elevation remained fully tied and supported by bespoke cantilever brackets.

Revision B: A critical breakthrough came with introducing a central core tower in the North light well, distributing the load more effectively. This central tower, combined with spine beams running from East to West, significantly reduced external leg loads. A concrete raft foundation further facilitated load distribution, eliminating the need for additional support weights, or “kentledge.”

Collaboration with structural engineers from Curtins and Wentworth House Partnerships led to the development of a ring beam system, redistributing localised loads and ensuring stability. The use of 3D design models by BDS allowed the scaffolders to visualise and execute this intricate scaffolding system with precision.

Collaboration with structural engineers from Curtins and Wentworth House Partnerships led to the development of a ring beam system, redistributing localised loads and ensuring stability. The use of 3D design models by BDS allowed the scaffolders to visualise and execute this intricate scaffolding system with precision.

Navigating Operational Hurdles

Logistical and operational challenges were ever-present, but the team’s meticulous planning and coordination ensured smooth execution. Strict Timelines: With a tight schedule to adhere to, detailed project planning and regular progress meetings kept the project on track. Logistical Coordination: The site’s historical nature demanded careful planning for the transportation and placement of materials. Coordination with Blackburn College and local authorities helped minimise disruptions. Resource Management: Securing experienced scaffolding operatives and high-quality materials was crucial. Continuous training ensured the team’s efficiency and adherence to high standards.The Path to Success

Key stages of the project highlighted the team’s expertise and adaptability:

Setting the Scaffolding Base: Aligning the scaffolding base correctly was paramount, considering the complex ties into the newly designed concrete raft foundation. The team’s meticulous approach ensured a stable foundation.

Cantilever Brackets Installation: Custom-designed cantilever brackets were carefully installed to support the West elevation without compromising its historical integrity.

Spine Beams Installation: Positioned with precision, the spine beams supported the temporary roof, providing a safe and effective solution for weather protection.

Temporary Roof Installation: The installation of the temporary roof ensured comprehensive coverage, allowing restoration work to proceed uninterrupted, regardless of weather conditions.

Key stages of the project highlighted the team’s expertise and adaptability:

Setting the Scaffolding Base: Aligning the scaffolding base correctly was paramount, considering the complex ties into the newly designed concrete raft foundation. The team’s meticulous approach ensured a stable foundation.

Cantilever Brackets Installation: Custom-designed cantilever brackets were carefully installed to support the West elevation without compromising its historical integrity.

Spine Beams Installation: Positioned with precision, the spine beams supported the temporary roof, providing a safe and effective solution for weather protection.

Temporary Roof Installation: The installation of the temporary roof ensured comprehensive coverage, allowing restoration work to proceed uninterrupted, regardless of weather conditions.

“Having been involved in the scaffold industry for almost 30 years, this scaffold design is the most complex I’ve worked on”

Achieving Recognition

As the Victoria Building restoration progresses toward its scheduled completion in September 2024, the project has already garnered widespread acclaim for its innovative design and seamless execution. Kevin Walsh, Senior Design Engineer at BAM Construct UK Ltd, remarked, “The design challenges were formidable, but the BDS team rose to the occasion. Their proactive collaboration with BAM’s site team and the Project Structural Engineer was instrumental in developing a workable design. Without this close cooperation, the temporary roof would have been an impossible feat.” Lee Buckley, Managing Director of Buckley Design Solutions, reflected on the project’s complexity, stating, “In nearly 30 years in the scaffolding industry, this design stands out as the most intricate I’ve ever worked on. The ability of the scaffolding team to execute the plan ahead of schedule is truly commendable.” Steve Bannister, Operations Director at Allied Access, echoed these sentiments, adding, “With over 40 years in the scaffolding industry across various sectors, this project has been a particularly rewarding experience. Early engagement with BAM, the client, and BDS was key to bringing this complex plan to life, and the collaborative effort has been nothing short of remarkable. “The Directors are immensely proud of the Allied team, whose professionalism and swift execution of this exceptional scaffolding structure deserve high praise.” BAM Construction Manager Mick Donoghue and Senior Project Manager Mark Hardisty concluded: “The Victoria Building Project presented a plethora of complex issues to overcome. Being a Grade II Listed structure requiring a complete reroof, it was imperative that the correct solution to safeguard these finishes whilst the works were being carried out was developed to prevent further damage to the internal fabric. With the early engagement of our supply chain partners, Allied Access and BDS, the team has worked hand in hand with BAM’s design and management teams to develop a scheme that achieves this without impacting on the listed façade.” “Our thanks go out to BDS and all involved in working so collaboratively to overcome the many challenges along the way.”A Vision Realised

The Victoria Building restoration is more than a project; it’s a labour of love and a testament to the expertise and dedication of Allied Access and Buckley Design Solutions. Their innovative approach and meticulous planning have helped preserve a piece of Blackburn’s heritage and set a new benchmark for future scaffolding and restoration projects.

In reviving the Victoria Building, the team has woven a story of collaboration, innovation, and respect for history. Their work ensures that this architectural gem will continue to grace Blackburn’s skyline for generations to come.

The Victoria Building restoration is more than a project; it’s a labour of love and a testament to the expertise and dedication of Allied Access and Buckley Design Solutions. Their innovative approach and meticulous planning have helped preserve a piece of Blackburn’s heritage and set a new benchmark for future scaffolding and restoration projects.

In reviving the Victoria Building, the team has woven a story of collaboration, innovation, and respect for history. Their work ensures that this architectural gem will continue to grace Blackburn’s skyline for generations to come. Scafom-rux UK Announced as Key Sponsor for ScaffCon24

Scafom-rux UK Ltd, a global provider of system scaffolding solutions, has announced its role as the headline sponsor for ScaffCon24.

The event, organised by the Scaffolding Association and regarded as one of the UK’s premier scaffolding and access industry conferences, will occur on October 11th at The Belfry Hotel and Resort. This strategic partnership highlights Scafom-rux’s unwavering commitment to advancing safety, technological innovation, and best practices within the sector. The company’s involvement as the headline sponsor reinforces its dedication to the industry and aligns with its mission to drive positive change and foster collaboration among professionals.“ScaffCon24 is a vital event for our industry”Andrew Smith, Managing Director of Scafom-rux UK, expressed his enthusiasm for the event, stating, “ScaffCon24 is a vital event for our industry, and as the headline sponsor, we are delighted to contribute to its success. Our mission aligns perfectly with the conference’s focus on safety, innovation, and collaboration. We look forward to engaging with fellow professionals and showcasing our latest solutions.” ScaffCon24 is set to attract company owners, industry experts, and scaffolding professionals from across the UK. The conference will feature thought-provoking sessions led by some of the industry’s most influential leaders, providing delegates with valuable insights into critical topics such as the latest safety regulations, best practices for working at height, and the evolving landscape of temporary works design and fleet vehicle operations. In addition to sponsoring the event, Scafom-rux UK will exhibit, offering delegates a chance to explore its comprehensive range of scaffolding products, accessories, and rental options. Attendees will also have the opportunity to engage directly with the company’s team of experts, who will be on hand to discuss the latest trends and innovations in the scaffolding industry. ScaffCon24 presents an invaluable opportunity for scaffolding professionals to expand their knowledge, network with peers, and discover the latest advancements shaping the industry’s future. As the scaffolding sector evolves, events like ScaffCon24 are crucial in ensuring that companies remain at the forefront of safety, efficiency, and technological progress. For more information and to book your tickets, visit the official ScaffCon24 website: www.scaffoldconference.co.uk.

JR Scaffold Supports Glasgow Hotel’s Student Housing Makeover

JR Scaffold Services, a leading division of The JR Group, has embarked on a landmark project to support the transformation of the former Lorne Hotel in Glasgow’s West End into high-end student accommodation.

This ambitious renovation, commissioned by the Parklane Group, marks the latter’s first major project in Scotland. Located at the corner of Derby Street and Sauchiehall Street, the Lorne Hotel is a notable landmark comprising two distinct buildings that have undergone several extensions and upgrades. The property includes a Grade A listed building at the rear, initially from the Edwardian and Victorian eras, alongside a more prominent modern extension constructed in the 1960s at the front. The renovation aims to convert the hotel into 147 luxurious studio apartments, maintaining the historical essence of the older structure while modernizing the newer section. Evan Horne, a JR Scaffold Services representative, highlighted the project’s complexity, given the diverse mix of building materials and architectural styles involved. “The Lorne Hotel has seen many facelifts and extensions over the years, so the fabric of the buildings is quite intricate. Our brief is to refurbish, repair, and regenerate this iconic property into luxury student accommodation, while also enhancing its thermal performance and integrating it seamlessly into the local urban landscape,” Horne explained. JR Scaffold Services’ role in the project is pivotal, providing the necessary scaffolding for the extensive internal renovations, the installation of a new external façade, and roofing works. The scaffolding will also support the construction of a new steel superstructure at the rear and the addition of a new level to the building. As the project progresses, the team will continually adapt and reconfigure the scaffolding to meet the redevelopment’s evolving needs. Work on the site commenced earlier this year, with a dedicated team of three full-time JR Scaffold Services employees expected to remain on-site until the project’s completion in early 2025. The JR Group, headquartered in Paisley, began as a scaffolding business and has since grown into one of Scotland’s largest building and construction firms, employing approximately 200 staff. With a solid reputation for delivering exceptional projects for leading UK housebuilders, social landlords, and private clients across Scotland and the North of England, this latest venture further cements JR Scaffold Services’ position as a key player in the region’s construction industry. “We are thrilled to be part of such a significant project,” said Horne. “Seeing this historic building in Glasgow’s West End brought back to life is something we’re all very excited about.”3M Issues Urgent Recall for Ultra-Lok Lifelines

3M Fall Protection has issued an urgent stop use and remediation notice for select models of their 3M™ DBI-SALA® Ultra-Lok™ Self-Retracting Lifelines due to a potential issue with supplied raw materials.

Please Note: This safety alert does not apply to products sold in Europe under the CE mark. The affected products, produced between November 17, 2023, and June 14, 2024, may fail to lock up properly or may inadvertently switch to retrieval mode during a fall, posing a serious risk of injury or death.Affected Products:

- 3503882: Stainless Steel Cable, 50 ft (specific lots impacted)

- 3503886: Galvanized Cable, 50 ft (all lots within date range)

- 3503887: Stainless Steel Cable, 50 ft (all lots within date range)

- 3503889: Stainless Steel Cable, 50 ft (specific lots impacted)

Immediate Actions for End Users:

Identify Affected Units: Check the model number, manufacture date, and lot number on the device label. Compare this information with the detailed list provided in the notice. Submit Repair Requests: If your unit is affected, submit a repair request using the provided QR code or visit the specified web link. 3M will cover repair and shipping costs. Await Instructions: Once your request is submitted, you will receive a repair authorisation number and return shipping instructions from 3M’s Block Repair Customer Service department.Actions for Distributors:

- Check Inventory: Verify if you have any of the impacted products in stock.

- Submit Repair Requests: Use the provided QR code to submit a distributor stock repair request. Forward the notice to customers who may have purchased the affected products and assist them as needed.

ScaffCon Shortlisted for Top Industry Award

The Scaffolding Association has announced that its annual Scaffolding Conference, ScaffCon, has been shortlisted for an accolade at the prestigious Memcom Excellence Awards.

The Memcom Excellence Awards celebrate outstanding achievements across a wide range of sectors, including professional bodies, trade associations, membership charities, trade unions, and the broader not-for-profit membership community. The awards encompass various categories that highlight excellence in strategy, leadership, engagement, publications, and individual and team accomplishments, aiming to honor innovation and superior performance in multiple areas. ScaffCon has been nominated in the “Best Event under £100K” category, competing against notable events organised by the Association of Chartered Certified Accountants, the Chartered Banker Institute, the Chartered Institute of Trade Mark Attorneys, the Railway Industry Association, and STEP.“Being shortlisted for a Memcom Excellence Award is a fantastic achievement.”Sally Smith, Head of Marketing and Events at the Scaffolding Association, expressed her excitement over the nomination: “Being shortlisted for a Memcom Excellence Award is a fantastic achievement. It underscores the dedication and hard work of everyone involved in making ScaffCon a successful event. We are thrilled to have our efforts recognised!” The winners of the Memcom Excellence Awards will be revealed at an elegant ceremony on Thursday, September 26th. This event is set to gather influential figures from various industries, celebrating remarkable achievements and sharing best practices.

Building a Stable Scaffolding Business

Industry leader Des Moore explores how to build a stable business—something that scaffolding businesses need to consider at all times, but that becomes even more critical during volatile economic periods.

In my previous articles for ScaffMag, I’ve talked about how to scale a business for sale. In short, the more stable and well-managed a business is, the more attractive it is to a buyer. But even if you have no intention of selling, you should still make it a priority to ensure your business is as strong and resilient as possible.

Not only is this important for your long-term personal success, but your employees rely on you for their livelihoods, and your clients rely on you to support them with their projects. As a company owner or leader, it’s your primary responsibility to build a stable business. And it’s even more important when the economy is volatile, when there are pressures on the sector, and when an election is looming – all of which we are facing at the moment.

In this article, I’m going to cover the business fundamentals that contribute to creating a strong business. These principles apply to companies of all sizes and in all stages of growth.

In my previous articles for ScaffMag, I’ve talked about how to scale a business for sale. In short, the more stable and well-managed a business is, the more attractive it is to a buyer. But even if you have no intention of selling, you should still make it a priority to ensure your business is as strong and resilient as possible.

Not only is this important for your long-term personal success, but your employees rely on you for their livelihoods, and your clients rely on you to support them with their projects. As a company owner or leader, it’s your primary responsibility to build a stable business. And it’s even more important when the economy is volatile, when there are pressures on the sector, and when an election is looming – all of which we are facing at the moment.

In this article, I’m going to cover the business fundamentals that contribute to creating a strong business. These principles apply to companies of all sizes and in all stages of growth.

Know what your business is for

Every business should have a ‘Raison d’être’ – you may wonder what this is. It’s simply a statement that sets out your company’s reason for being. You should also have a vision of where you want the business to be in the next five years, and you should have a set of values that reflects your individual approach. This shows your clients that you have a clear purpose, and that your employees understand what that purpose is. It also gives you a clear target for where you want your business to go – and that forms the central part of your business strategy.Manage the bigger details

A strong business has to be built on the details. This means having an up-to-date budget that supports your business strategy. It means ongoing cashflow management, and it means having an action plan that sets out how you are going to achieve your goals. You should also consider essential factors like timely agreements of variations to contracts, as this can have a significant detrimental impact on your working capital. Measure your progress against these strategies on a regular basis – at least once per month – so you can make any changes you need.Make sure you have a mix of work

The broader your spread of work, the less reliant you are on one customer or one job. You’re also not committing all your resources and equipment in one place, so you are lowering your risk all round. By taking on a range of project sizes, for example, you can make sure you are keeping your cashflow healthy and not overcommitting the business to any one project.Don’t rely on three or four primary customers

It’s important to build good relationships with your customers, and take on plenty of repeat work. But if you only have a small number of main customers, you are creating a huge potential risk for your business. What happens to your company if one or more of those companies fail, or you fall out with them? You will lose a significant proportion of your work overnight and this could put you in a very difficult position – particularly if there is a large amount owed to you. If you are in this position now, you should look for ways to balance these customers with other work, to give you a safety blanket sooner rather than later.Accept a measured level of risk

Every business has risk. The question is, how much are you prepared to accept? If your aim is to build a stable business that can withstand market, economic or any other shocks, you need to accept a level of risk, but minimise it where possible. I’d say have at least 75% of your business insured. Be realistic and detailed about the risks facing your business, mitigate them wherever possible and review them regularly.Work across multiple sectors

Every sector is subject to its own risk. So, to protect your business, it’s safest to spread your work across several sectors. For me, four sectors is optimal – you are able to understand your customers’ needs and develop expertise in each sector, but you are not overcommitted to any single one, and you will know the risk to your business of work disappearing from any one of those sectors. In particular, stand back and look at the types of contracts you have – are they progressive, where you are regularly supplying scaffolding so your cashflow is constant? Or are they static, where you get a payment when the scaffold is erected and then nothing for many months – or even years – until it’s time to take it down?Manage your cashflow

When smaller or owner-managed businesses fail, it’s often because of poor cashflow management. It’s absolutely imperative to understand both how cash comes into your business and how it goes out. Generally, this is referred to as Days Sales Outstanding (DSO) – the number of days it takes for payments to come in from clients – and Days Payable Outstanding (DPO) – the time it takes to pay your own suppliers. Simply put, if you don’t have a grip on this, you could end up with a mismatch that has a serious impact on your cash position, and your working capital will be squeezed.

When smaller or owner-managed businesses fail, it’s often because of poor cashflow management. It’s absolutely imperative to understand both how cash comes into your business and how it goes out. Generally, this is referred to as Days Sales Outstanding (DSO) – the number of days it takes for payments to come in from clients – and Days Payable Outstanding (DPO) – the time it takes to pay your own suppliers. Simply put, if you don’t have a grip on this, you could end up with a mismatch that has a serious impact on your cash position, and your working capital will be squeezed.