IDH Launches new housing design division

Lee Marley opens new London HQ

Michael Tame MRICS, Commercial Director at Lee Marley Brickwork added: “As we see natural growth within our business operation it was important to us to create an environment that allows our employees to achieve their full potential. A key passion of ours is our Graduate and Apprenticeship Schemes which promote young talent.

The opening of our Notting Hill office will promote a friendly hub for our graduates to base themselves from. The office provides collaborative workspaces, offices and a large boardroom with state-of-the-art conference and presentation software, ideal for online and in-person training.

Our clients are key to the strength of our business, and it is our intention to use this new workspace to invite our clients to and display some of our work, of which we are extremely proud of. We are excited to enter 2022 in such a fortunate position.”

Michael Tame MRICS, Commercial Director at Lee Marley Brickwork added: “As we see natural growth within our business operation it was important to us to create an environment that allows our employees to achieve their full potential. A key passion of ours is our Graduate and Apprenticeship Schemes which promote young talent.

The opening of our Notting Hill office will promote a friendly hub for our graduates to base themselves from. The office provides collaborative workspaces, offices and a large boardroom with state-of-the-art conference and presentation software, ideal for online and in-person training.

Our clients are key to the strength of our business, and it is our intention to use this new workspace to invite our clients to and display some of our work, of which we are extremely proud of. We are excited to enter 2022 in such a fortunate position.”

Actavo secures build contract with one of the UK’s largest telecoms operators

TR Scaffolding and UKSSH hit the gold standard

First CISRS training centre opens in Russia

A successful accreditation audit last week has allowed the centre to now offer CISRS OSTS training.

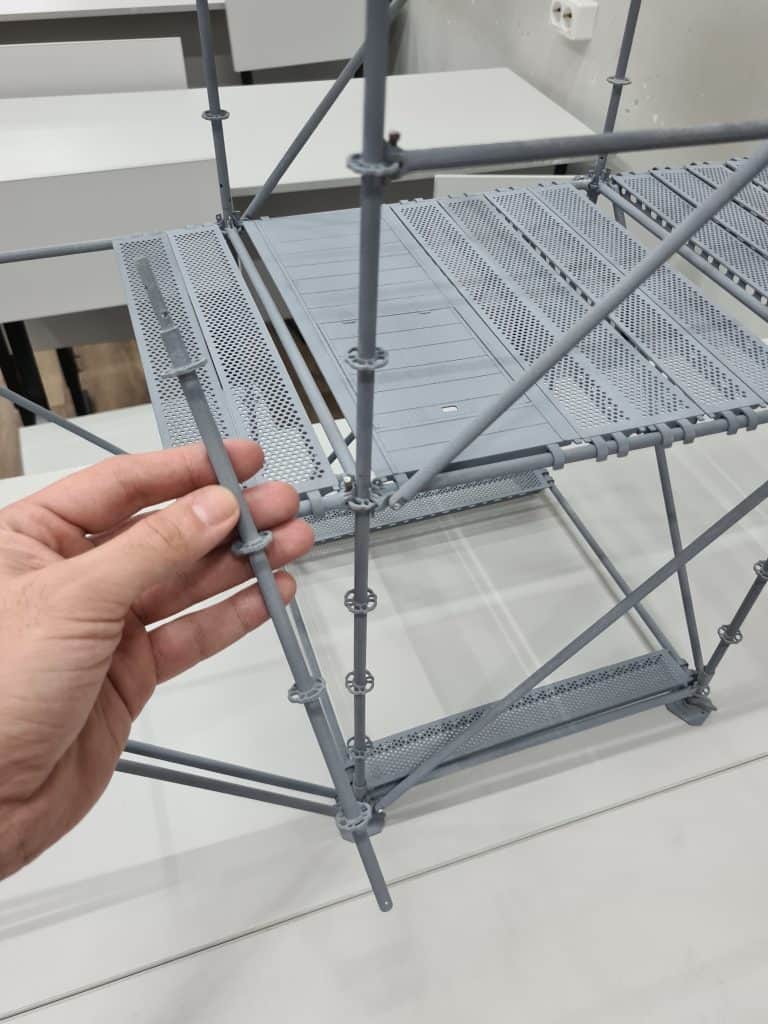

Dave Mosley, CISRS Managing Director, said: “The centre is fitted out to the highest specifications, with brand new materials, tools and PPE. There are several classrooms but one is particularly impressive as it houses both an independent and a hanging scaffold actually within the classroom.”

SIMIAN International Managing Director Ian Fyall added: “We are delighted to be partnering Prostaff in this venture and moving both SIMIAN and CISRS’ footprint into another part in the world. We are looking forward to training and assessing their instructors and giving advice and guidance going forward.

“It’s been 12 months in the making due to Covid but we eventually got there”

Dave Mosley, CISRS Managing Director, said: “The centre is fitted out to the highest specifications, with brand new materials, tools and PPE. There are several classrooms but one is particularly impressive as it houses both an independent and a hanging scaffold actually within the classroom.”

SIMIAN International Managing Director Ian Fyall added: “We are delighted to be partnering Prostaff in this venture and moving both SIMIAN and CISRS’ footprint into another part in the world. We are looking forward to training and assessing their instructors and giving advice and guidance going forward.

“It’s been 12 months in the making due to Covid but we eventually got there”

G&M Celebrates 20 Year Anniversary and Launches G&M Group

G&M Group Managing Director, Mark Pickles said: “The launch of the G&M Group brand is a fantastic way to celebrate two busy, successful decades of trade within the construction sector.

We are so lucky to have kept some of original team members – including Sean Barber – and to have such a great team of people in the office training centre and on-site installing. WE are a great team offering the best products, training and customer service.

“And with three new safety-enhancing, time and money-saving products about to launch in 2022, the future looks bright for the G&M Group and our many valued customers. Here’s to the next 20 years!”

G&M Group Managing Director, Mark Pickles said: “The launch of the G&M Group brand is a fantastic way to celebrate two busy, successful decades of trade within the construction sector.

We are so lucky to have kept some of original team members – including Sean Barber – and to have such a great team of people in the office training centre and on-site installing. WE are a great team offering the best products, training and customer service.

“And with three new safety-enhancing, time and money-saving products about to launch in 2022, the future looks bright for the G&M Group and our many valued customers. Here’s to the next 20 years!” Scaffold designers expand into Scotland

National protests planned for Scunthorpe scaffolders

Scaffolding supplier offers sheeting that ‘eats’ pollution

BLC Construction Supplies is offering its customers ReActivair – a special coating that eats pollution that can be used for a wide range of scaffold sheeting applications.

ReActivair, the pollution-eating speciality coating is made from naturally occurring materials that improves air quality by using energy from natural sunlight to break down harmful pollutants and odour molecules in the air. When sunlight hits the ReActivair coating, it prompts a series of reactions taking humidity and oxygen from the air turning them into cleaning agents that scrub the air of volatile organic compounds (VOC’s) and Nitrious oxides (NOx), also known as smog.Bristol-based BLC Construction Supplies say It can be used on a wide range of sheeting applications like Building wraps, Scaffold sheeting, Netting and Rail and Roadside billboards.

Results from tests at Sheffield University show 1m2 of coated material can take out approx 2g of NOx per day. As an example, just 1 roll of 2m x 45m scaffold sheeting (c.90m2) coated completely with ReactivAir, will potentially remove the pollution created by 250 cars, every week.

To find out more about ReactivAir visit https://blccs.co.uk/product/reactivair/

Building charity targets a record number of life-changing projects for 2022

- A 51-year-old father of four in Hertfordshire who fell 20 ft from scaffolding after having a seizure and has since been diagnosed with a brain tumour

- A 40-year-old man from Walsall who suffered spinal cord damage after a heart operation went wrong and left him permanently disabled

- A 63-year-old former brickie from Northern Ireland who suffers from progressive multifocal leukoencephalopathy (PML) – a breakdown of his immune system

- An electrician from Loughborough whose 5-year-old son has cerebral palsy and cannot sit up unaided

- The wife of a plasterer from South Shields who has ovarian cancer, which is spreading

- A 55-year-old father of two who was a building surveyor before he suffered a hypoxic brain injury caused by lack of oxygen due to a heart attack, currently in neuro rehab