Homes, schools and hospitals across England are set to be greener and cheaper to run thanks to a £3 billion plan to upgrade the nation’s buildings

Around 120,000 construction jobs are expected to be supported by the new government funding schemes launched today. Homeowners can sign up for big savings on upgrades to their homes under the government’s £2 billion Green Homes Grant. And an additional £1 billion was announced to improve the energy efficiency of publicly owned buildings. Many scaffolding businesses could see an influx of new enquiries as grants offered will cover green home improvements ranging from the insulation of walls, floors and roofs, to the installation of double or triple glazing. The launch of the Green Homes Grant forms part of a wider plan to upgrade the nation’s buildings which also includes:- £1 billion to boost the energy efficiency of public buildings, including schools and hospitals through a Public Sector Decarbonisation Fund

- new measures to ensure nearly 3 million privately rented homes are upgraded to modern energy efficiency standards by 2028

- £50 million to improve the energy efficiency of social housing

“I urge everyone to visit the Green Home Grants website to see how they can make the most of this fantastic scheme.”

Chancellor Rishi Sunak said: “We promised to support jobs and protect the environment – and the Green Homes Grant delivers on this. We’re giving homeowners, landlords and local authorities the funding they need to hire local tradespeople and make our homes more energy-efficient. By supporting the green van men and women, we’ll save money, save jobs and save the planet.”

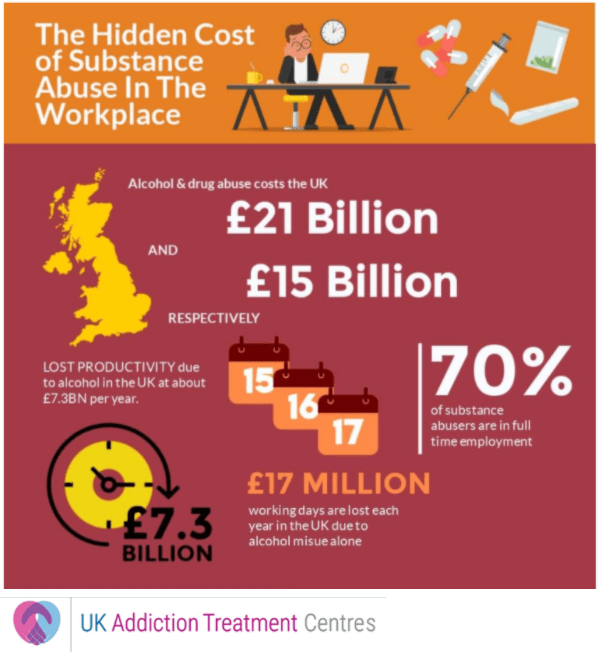

UKAT’s Head of Treatment, Nuno Albuquerque, told Scaffmag the importance of taking preventative action in order to protect staff, he said: “We know that as an employer, the employees come first. Looking after the mental well-being of your workforce is not just beneficial for them, it’s beneficial for your business too.

Employees who feel supported by management will always find it easier to stay in work or return quicker after any absences, which ultimately saves you money.”

“Those who are uncomfortable in opening up about addiction are likely to silently suffer, which could lead to them being unable to carry out their duties, increasing the possibility of a health and safety risk; not a risk worth taking in the scaffolding and construction industries.

“We understand that this is a sensitive subject and one that should be discussed with experts. That’s what we’re here to do. Together, we can help your workforce and in turn, help you and your business thrive during these difficult times.”

It’s not only UKAT’s figures which suggest proactive steps need to be taken.

A survey by

UKAT’s Head of Treatment, Nuno Albuquerque, told Scaffmag the importance of taking preventative action in order to protect staff, he said: “We know that as an employer, the employees come first. Looking after the mental well-being of your workforce is not just beneficial for them, it’s beneficial for your business too.

Employees who feel supported by management will always find it easier to stay in work or return quicker after any absences, which ultimately saves you money.”

“Those who are uncomfortable in opening up about addiction are likely to silently suffer, which could lead to them being unable to carry out their duties, increasing the possibility of a health and safety risk; not a risk worth taking in the scaffolding and construction industries.

“We understand that this is a sensitive subject and one that should be discussed with experts. That’s what we’re here to do. Together, we can help your workforce and in turn, help you and your business thrive during these difficult times.”

It’s not only UKAT’s figures which suggest proactive steps need to be taken.

A survey by