PERI’s scaffolding division set for growth following key appointment

System scaffolding manufactures PERI has appointed Charles Stratford as its Business Development Manager for PERI UP.

The company says the appointment will enable it to develop its scaffolding proposition, so that it is more aligned to meet the growing demand for skilled workers, efficient solutions and digitalisation, now and in the future.

Charles joins PERI with over 20 years’ experience in the industry. The balance between his practical knowledge as a scaffolder early on in his career, coupled with his strategic acumen in recent senior roles made him the right candidate to navigate this new journey for PERI.

Charles will focus on how key challenges such as productivity and safety on site can be overcome by leveraging the benefits of system scaffolding.

Supported by a network of specialists across PERI and a new multimillion-euro production and galvanising plant in Germany, Charles is looking forward to growing PERI UK’s scaffolding division.

Commenting on his appointment, Charles Stratford said, “The features of system scaffold are inherently aligned to the productivity and safety measures that are expected on-site today. Something I am excited about is working with our designers on larger, more bespoke scaffolding solutions for our customers.

We have the right people, the right solutions and the right product for any scaffolding-related service our customers require, giving us the confidence to fulfil any requirement here at PERI.”

Small Business Confidence Bounces Back After Lockdown

Business finance study reveals predictive growth for UK small businesses has almost doubled in just three months.

Research carried out by Hitachi Capital Business Finance shows the proportion of UK small businesses predicting growth has almost doubled in just three months from 14% to 27%. It could be one of the first tangible indications that the Government’s easing of lockdown is having a positive impact on a key area of the UK economy. The quarterly tracking study goes beyond sentiment and confidence, says the business finance company. It examines the percentage of small businesses that actually predict growth in the next three months. Following last quarter’s report, which saw the percentage of small business owners predicting growth plummeting from 39% to just 14%, the new findings show the highest quarter-on-quarter rise in five years. With 27% predicting growth overall, there were significant rises in the percentage of small businesses predicting moderate expansion the next three months (up from 10% to 23%) or no change (26% to 43%). This meant there has been a huge reduction in the percentage of businesses that fear contraction (down from 31% to 19%) or collapse in the next three months (down by almost two thirds from 29% to 11%). By sector, the IT/telecoms sector had the highest proportion of small businesses that predicted growth for the three months to 30th September (44%). The biggest rises in confidence since lockdown were evidenced in and transport and distribution (up from 8% to 34%) and manufacturing (9% to 30%), where the resurgence of growth forecasts was striking. There were also significant rises in sectors hardest hit by lockdown: In retail, the percentage of small businesses predicting growth rose from 21% to 27% – and in hospitality growth forecasts rose from 11% to 16% in the three months since April. The research also suggests that smaller, more agile enterprises will be the fastest to adapt to the UK’s re-emergence from lockdown: Small businesses that had been trading for less than five years (35%) and those that employed 10-49 employees (37%) were most likely to predict business growth for the next three months (to 30th September). Gavin Wraith-Carter, Managing Director at Hitachi Capital Business Finance commented: “The latest Hitachi Capital research findings are remarkable for both the scale and the speed of the revival in small business confidence. We knew last quarter that small business confidence would fall as lockdown started and the scale of the fall was a concern, particularly the steep rise in the number of business owners fearing for their survival. Our new research – just in – shows what an immediate and positive impact the easing of lockdown has had on the small business community. Whilst bigger businesses are having to adjust and adapt at a slower pace, small business confidence across the UK has bounced back and as the engine room of the British economy, today’s figures can give us confidence that small businesses will lead the nation’s effort to rebuild the economy and secure growth.”System scaffolding can help with social distancing, says TRAD

TRAD UK believes the use of system scaffold, and in particular, their own PLETTAC METRIX system can help with social distancing, productivity and cost savings.

During the current Coronavirus COVID-19 pandemic, the UK Government has stated that the construction industry has a huge role to play in supporting the health of the economy and is making a highly valued, and somewhat critical, contribution. However, the difficulties this brings to the workplace, with sites striving to comply with the Site Operating Procedures developed by the Construction Leadership Council, are hard to overcome when related to safe systems of work in the scaffolding sector. TRAD UK believes that these problems and issues can be somewhat alleviated by careful planning, and the use of system scaffold such as the highly developed PLETTAC METRIX system. TRAD UK’s Head of Technical Sales, Alan Slater explains; “With the system being much faster to install than traditional methods, the reduction in erection times for PLETTAC METRIX can go some way to offset the extra time required and the decrease in productivity that the new COVID-19 working practices bring. The very nature of the system means fewer small components are required, which helps to avoid close proximity contact, therefore allowing for easier adherence to the current Social Distancing rules. The use of base collars on the bottom lift makes it far easier for members of scaffold gangs to keep a Social Distance from one another. When commencing a build, two operatives are not required to hold and fix standards, ledgers and transoms until they are all secure, as it is possible for one operative to complete this task whilst the other members of their gang can work nearby on other tasks and areas of the structure being built, although it should be noted that it is not implied that lone working should be employed, as a minimum of two operatives should be working within the same vicinity, while Socially Distancing. Furthermore, as it is only the base lift which needs to be levelled, productivity is increased with PLETTAC METRIX as this repetitive process, which is completed at every level on traditional tube & fitting scaffolds, is only required once.” Alan goes on to say: “The efficiencies that PLETTAC METRIX can generate, with a general reduction in labour costs of up to 30% to 50% when compared to tube & fitting scaffolds, gives our customers an edge in the market place, making them more streamlined and better placed to cope with the added pressures that an economy affected by recession brings, helping to manage current outgoings whilst investing for the future. Generally, as there are less components and weight of materials required per job, this means there is less transport required, which therefore necessitates less visits to site for transport personnel, the consequence of which is less exposure to risk. The “divisibility” of the components – which improves flexibility & adaptability – when compared to other similar systems, means a reduction in the amount of components required, again helping with productivity and less close proximity contact. In addition to the improved safety and adherence to SG4 that the optional Permanent Advanced Guardrail brings, this award winning feature has a positive effect on productivity. The one fix installation process of the guardrail replaces either two or three ledgers (depending on the size and type of guardrail), reducing the amount of equipment which is required to be manually handled and subsequently lessens the risk to the operatives. The PLETTAC rosette & wedge head junction forms an incredibly strong joint, allowing up to eight components to be fixed in the one node. This allows for a far less reliance on small fittings, with the wedges being much faster to secure than traditional fittings, once again helping with productivity and social distancing.” Plettac Metrix is available on a hire or sale basis at six TRAD UK locations strategically positioned throughout the country. If you would like to try this revolutionary product for yourself, to experience the difference it can make, please contact 0845 899 0845 / [email protected] or your local depot: Andover 01264 350 505 | Birmingham 0121 522 2333 |Stockport 0161 430 4666 | London 020 8517 1212 | Leeds 0113 249 9555 | Glasgow 0141 550 3666NASC Update COVID-19 Guidance

The NASC has updated its guidance for Scaffolding Operations During Coronavirus Pandemic

The updated COVID-19 guidance published by the National Access and Scaffolding Confederation is now at version 3. The latest guidance from the NASC comes after the Construction Leadership Council updated its own Site Operating Procedures, and to ensure the NASC remains inline with the relaxing of Government guidance – ‘Working safely during COVID-19 in construction and other outdoor work – Version 4’. The twelve paged NASC document titled Scaffolding Operations During the Coronavirus (COVID-19) Pandemic Version 3 mainly covers the ‘relaxed’ social distancing rules, it now allows 2.0m or 1.0m with risk mitigation measures where 2.0m is not viable and a few other relatively minor additional requirements. The latest version is available hereNew Fleet Acquisition for Caspian Group

Caspian Group continue their expansion with further investment in their transport fleet.

The Scunthorpe based scaffolding supplier recently added a new Renault D26 wide 6×2 truck to their growing range of vehicles, acquired from Thompson Commercials Ltd, with whom they have worked with to secure most of their current fleet. With the fleet ranging from 3.5 tonne vehicles through to 26 tonne vehicles, which also includes HIAB loader crane trucks, Caspian have incredible flexibility and reliability to meet the growing requirements of their customers across the UK. “Our in-house transport is vital to the success of our business, ensuring our customers receive their orders on time, every time, anywhere in the UK” says Managing Director, Neil Garrison. “Our fleet gives us total control and full flexibility to be able to meet any demands that our customers have, enabling us to provide even higher levels of service.” Investing in their transport fleet is just part of Caspian’s continued growth, having already invested significantly in their Scunthorpe scaffold board manufacturing facility and acquiring a new three-acre site on Scunthorpe’s Grange Lane over the past 18 months.Actavo expands Shoring operations into Scotland

Actavo Hire and Sales has announced that it will continue to expand its shoring operations across the UK starting with Glasgow.

The company has twenty-three branches in the UK and has established Shoring operations in Uxbridge, Raunds and Birmingham. The company’s UK shoring operation is focussed on a range of trenching products ensuring excavation work is carried out using the safest equipment. Actavo Shoring supply Trench Boxes, Manhole Boxes, Drag Boxes, Lightweight Box Systems, Closing Panels, Trench Sheets, Manhole Braces, Walers, Struts, Edge Protection, Fall Arrest Systems, Pipe Stoppers, Gas Detection and other related Shoring products. The existing shoring business was established in 2012 and has secured contracts throughout the South of the UK. Opportunities in Scotland have presented the company with its next move further North to develop its presence, grow its geographic reach and establish a base to grow. Peter Bavister, Director of Shoring UK says, “We are delighted to announce that we are pressing forward with our growth plans and it is a strong testament to the resilience and stability of Actavo Hire and Sales to be doing so given the current situation around the world. We are confident that we have the resources and demand to make this another success in our Shoring Division.” Shoring operations will be open in Glasgow on the 13th of July and will be operating out of Actavo Hire and Sales flagship branch in Scotland located at 2580 London Road, Glasgow, G32 8XZ. “We’re looking forward to offering Shoring products for Hire and Sale across the North of the UK and the stronghold in Glasgow allows us to provide our well-renowned products and services to more of our loyal customers” says Bavister.Scaffolding group announces big recruitment drive after £2M contract win

The JMAC Group are set to create 40 full-time jobs in the North East following over £2m in contract wins and exports to Europe.

The Teesside based group, consisting of J Mac Scaffolding, J Mac Safety Systems & J Mac Industrial Services are proving there’s some positivity on the job front as the COVID pandemic restrictions ease.

Following on from the chancellor’s announcement 8th July, the group has started by launching a national recruitment drive with central office positions based in the Teesside region.

Whilst the impact of the coronavirus has forced many companies to lay off staff, JMAC Group are looking ahead and creating opportunities for a diverse range of skillsets.

The JMAC brand is well known in Teesside and many people will recognise the name from their original company, JMac Scaffolding, which has been part of the construction industry for almost four decades now.

Since then, the JMAC brand has expanded and grown to such an impressive extent they are now looking for more people than ever & showing no signs of being slowed down by recent events.

Within the past month, almost all of their staff have returned from the Government Furlough Scheme, and have now started as they mean to go on, with the appointment of the Group Head of Finance &, Head of Marketing, Hire/Sales Controller/Office Manager, along with a temporary Industrial Operations Manager. The current roles they are actively recruiting for are:

- HR & HSEQ Coordinator

- Business Development Manager

- Industrial Operations Manager

- 5 Hire & Sales Representatives (National) Scotland, Yorkshire and Humberside, South East, North West, Midlands.

- 25 Scaffolders

- 4 Safety Decking Installers

- 2 Drivers

- 2 Yard Operatives

Speaking of the recruitment drive, JMAC Group MD Luis McCarthy said: “The JMAC brand began back in 1981 in Teesside, and that’s something we’re very proud of. Our heritage means we’ll always look to support our area and the people in it. Where possible, we use local suppliers, local people and local products to drive a variety of areas in our business and the coronavirus setback will not stop us from doing so.

The pandemic hit us hard, as it did for many people, but we are coming back harder and faster than ever with a spring in our step following commercial support from Santander & Clive Owen. We are now in a position to create almost 40 Full-time Jobs in the area following over £2m in contract wins and our first exports to Europe.”

Hire & Sales Manager, Aaron Foley, added: “We’ve spent the past few months pushing to ensure we can continue as normal as possible with JMAC after lockdown and it’s really paying off for us. We’ve recently sold a large number of our BrickGuard products to Total in Belgium. We’ve won new contracts with large clients such as Vistry Group, Tolent & Countryside Properties, Thirteen Group, not only this, our locally manufactured products have been dispatched to Persimmon Homes in Scotland showing the construction and housing market is well and truly back.

There are so many exciting things happening, it’s a great time for people to join our team.”

You can contact the JMAC office on 01642 563696 if you have any questions.

TRAD UK enters second phase of replacing 8,000 tonnes of rival Layher stock

The second package of TRAD UK’s 8,000 tonnes of rival Layher Allround system is now up for sale after the firm decided to replace its stock with its own PLETTAC METRIX system last year.

Following the successful completion of the first stage, TRAD UK is now set to commence with the second phase of the programme to replace TRAD Scaffolding’s stock of 8,000 tonnes of Layher Allround with ALTRAD’s system scaffold, PLETTAC METRIX. The system which its maker’s state can dramatically cut the cost of scaffold projects, whilst also improving both on-site productivity and safety. Des Moore, TRAD UK CEO said: “As I stated when we initially embarked on this programme of replacement, the added efficiencies which this provides will not only further grow TRAD Scaffolding’s operational capabilities but will also ensure we can continue to provide cutting-edge scaffolding solutions to our clients. PLETTAC METRIX has proven itself to be one of the most advanced ring-based system scaffolds and is significantly faster than traditional Tube & Fitting Scaffolding, generally giving labour savings from 30% to 50%.” “Since becoming part of the Altrad Group, TRAD has benefitted from significant investment and subsequent growth and this trend continues with further development of the PLETTAC METRIX scaffold system – manufactured in Germany by ALTRAD PLETTAC – including newly implemented automation to increase manufacturing capacity to meet demand.” TRAD believes the PLETTAC METRIX system has many advantages over other ring-based system scaffolds. And being a true modular scaffolding system, PLETTAC METRIX is suitable for use in all construction, heavy-duty industrial and civil engineering applications and is easily palletised allowing for optimal transportation. TRAD Scaffolding was one of the first companies to recognise the advantages and benefits which a systemised scaffold afforded some 25 years ago, and quickly introduced it into all sectors in which it worked. TRAD UK now believes that PLETTAC METRIX takes system scaffold to the next level. If any TRAD UK customers are interested in purchasing TRAD Scaffolding’s Layher stock, please email [email protected] for further details.Scaffolding Training Resumes After Lockdown

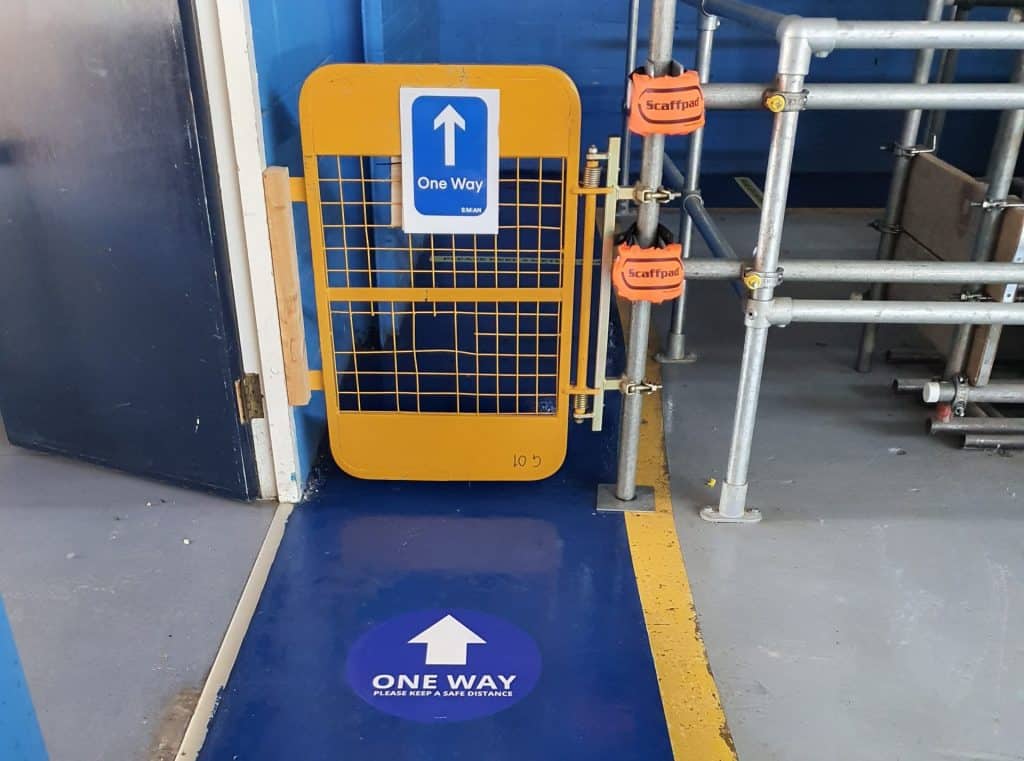

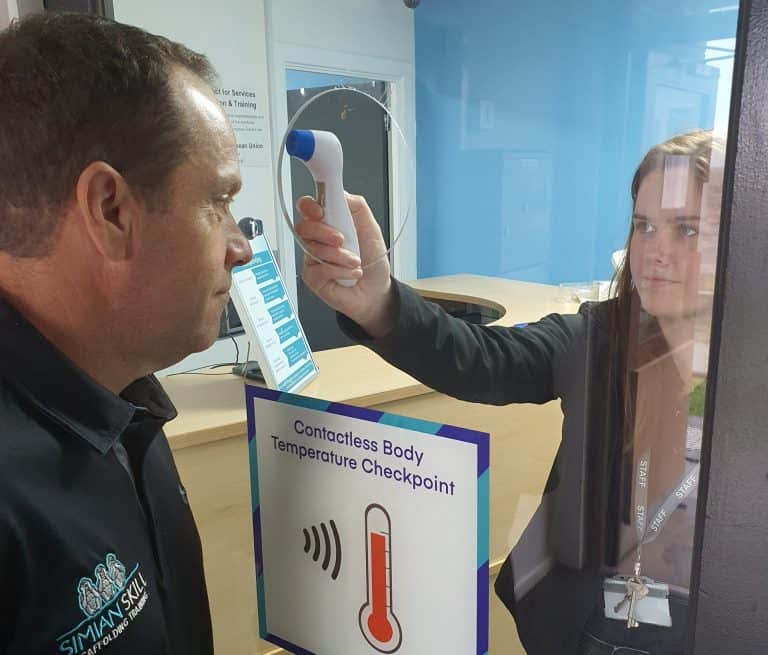

UK Scaffolding training providers are adapting to a ‘new normal’ after cautiously reopening their doors post lockdown.

Scaffolding training is now underway at over 18 locations around the UK, with many more to follow suit in the coming weeks. Providers are showing real resilience after swiftly adapting to overcome government restrictions. The Construction Industry Scaffolders Record Scheme (CISRS) has been working tirelessly with training providers throughout the lockdown to get them back open and COVID ready. Before reopening, CISRS has said that all centres were required to submit detailed risk assessments and method statements with supporting documentation and photographic evidence showing restrictions and precautions put in place to prevent the spread of Covid-19, whilst delivering training. Providers had to cover each step of the training experience from arriving at the centre, moving around the site, getting to classrooms, practical training areas, welfare facilities and getting back home safely. Although, the reduced centre capacity restriction is causing a strain for a number of providers the industry demand for CISRS training is unfaltering. So much so, Scaffmag understands that several scaffolding training providers are laying on extra courses in particular short duration ones like COTS and CPD.