Scaffolder Callum Jones is due to appear on ITV’s hit TV show Love Island.

The 23-year-old scaffolder from Manchester is employed by Connolly Scaffolding Ltd. He is set to enter Love Island’s swanky Cape Town villa this coming Sunday.

Speaking about his new role, Mr.Braithwaite said: “I am really looking forward to getting started and would encourage NASC members to get in touch if they have a technical query they need help with.

“It’s great to join the NASC’s executive team, which plays such a key role in supporting the NASC membership as well as the scaffolding industry as a whole.”

Mr.Braithwaite replaces Ken Johnson, who held the role for more than seven years.

Robin James, NASC Managing Director, said: “I’d like to welcome Dennis to the NASC team. He has extremely large shoes to fill in replacing Ken but we’re sure if anyone can carry on the outstanding work Ken undertook on behalf of the confederation then it’s Dennis.”

Scaffolders competed in the first-ever international scaffolding championships held at RESTA the countries largest trade fair in Vilnius, Lithuania.

Lithuania holds first ever Scaffolding Championships

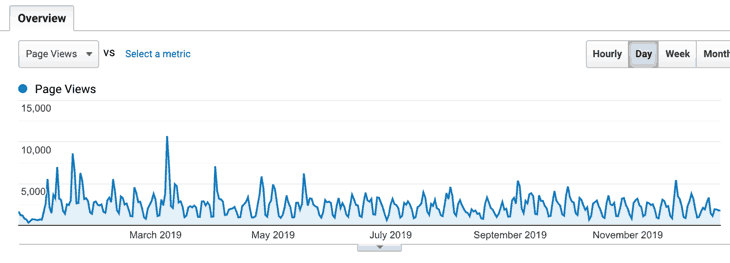

ScaffMag has the largest following of any scaffolding related page on Facebook. Our social media community on Facebook alone now stands at a massive 80,961 likes with more than 135,000 followers from around the world.

Twitter: @ScaffoldingNews 7,148 Followers

Instagram: @scaff_mag : 3,680 Followers

The ScaffMag quarterly magazine’s digital version has also enjoyed increased readership with just under 28,000 reads and over 90,000 impressions on issuu.

ScaffMag has the largest following of any scaffolding related page on Facebook. Our social media community on Facebook alone now stands at a massive 80,961 likes with more than 135,000 followers from around the world.

Twitter: @ScaffoldingNews 7,148 Followers

Instagram: @scaff_mag : 3,680 Followers

The ScaffMag quarterly magazine’s digital version has also enjoyed increased readership with just under 28,000 reads and over 90,000 impressions on issuu.

Our daily and weekly rundown email newsletters now have over 7,400 subscribers.

If you are interested in booking an ad campaign with us in 2020 and join our growing band of advertisers please contact us at [email protected]

We would like to wish all our readers a very Merry Christmas and a prosperous and Happy New Year. See you in 2020.

Our daily and weekly rundown email newsletters now have over 7,400 subscribers.

If you are interested in booking an ad campaign with us in 2020 and join our growing band of advertisers please contact us at [email protected]

We would like to wish all our readers a very Merry Christmas and a prosperous and Happy New Year. See you in 2020.

The three-year agreement includes mechanical, access, insulation and painting (MSIP) services at its two UK manufacturing facilities. It covers CF Fertilisers’ nitrogen complexes at Billingham in Stockton-on-Tees and Ince in Cheshire.

Employees of existing on-site contractors affected by this change will transfer to Bilfinger to create a consolidated multi-discipline maintenance delivery team for each site.

Phill Maurer Managing Director at Bilfinger UK said: “This award is a strategic win for Bilfinger and a key part of our ongoing drive to become the multi-disciplinary partner of choice within the process industry for intelligent and innovative maintenance programmes.

“CF Fertilisers is a prestigious name in UK industrial manufacturing, and an important addition to our client book in the sector.”

David Hopkins, Managing Director at CF Fertilisers said: “Our Billingham and Ince sites are both multifaceted facilities consisting of multiple production plants and supporting infrastructure. Maintaining these assets efficiently and with the highest standards of health and safety is a complex challenge, and Bilfinger’s track record in successful delivery of this kind of contract made the business our partner of choice.”

CF Fertilisers makes 1.5 million tonnes of fertiliser per year in the UK, supplying 40 per cent of the country’s demand, as well as half a million tonnes of related chemicals annually.

“The fact the financial markets have responded positively is an indicator of greater confidence, especially seeing the lift in shares for housebuilders.

“We are optimistic the construction industry will benefit from the Conservative manifesto pledge to build more homes, create more apprenticeships and crackdown on late payments.

“As a business, we hope the reduction in uncertainty will help to stabilise the market we work in. However, we are realistic that there are still a couple of difficult years ahead post Brexit.”

Robin James, Managing Director of The National Access and Scaffolding Confederation (NASC) told me: “The election result will free up the gridlock as the uncertainty around Brexit has now been removed,” said Robin.

“But clearly the detail now needs to be worked out. The industry as a whole will no longer be plagued by political division as there is now a clear mandate to proceed with Brexit. This will enable everyone to move forward,” he concluded.

Robin James, Managing Director of The National Access and Scaffolding Confederation (NASC) told me: “The election result will free up the gridlock as the uncertainty around Brexit has now been removed,” said Robin.

“But clearly the detail now needs to be worked out. The industry as a whole will no longer be plagued by political division as there is now a clear mandate to proceed with Brexit. This will enable everyone to move forward,” he concluded.

BGB Scaffolding has enjoyed its “best-ever year” by growing its workforce to 26 people and receiving top industry prizes.

Led by Managing Director Ben Badham, the Kinmel Bay-based firm was named Business of the Year (Under 100 staff) at the second annual Welsh SME Business Awards in Cardiff.

They also took home the overall winner prize, and in past weeks trainee Jamie Hargraves won the Apprentice of the Month title at the CITB National Construction College (NCC) in Birmingham.

BGB Scaffolding has also reinforced its partnership with Orsted, the global leader in offshore wind, supplying and constructing scaffolding on the world’s two largest windfarms – Walney Extension off Barrow-in-Furness, and Hornsea One off the east coast of Yorkshire.

Looking ahead to 2020, the 38-year-old is aiming for a further 20% turnover rise and revealed the business is now operating on three further sites on the southeast coast.

They have also just received an order from a leading cable supplier for an ‘access package’ on another new project in the region in 2020.

“It’s been an amazing year, our best-ever,” said Ben.

“To be nominated at the Welsh SME Business Awards was a huge honour, and to win two prizes was fantastic.

“It gives you a real sense of achievement to be recognised outside of the scaffolding sector and to be in the company of so many great Welsh businesses.

“I’m also delighted our apprentice Jamie has been given recognition for his efforts; his attitude to work is exemplary and I see a fantastic future for him with BGB. He is aware of the career and training path that we set out for all employees and is developing into a really great person as well as a competent scaffolder.”

Ben added: “It’s been an outstanding 12 months; turnover was up 50% and we are targeting another 20% increase next year.

“We are also looking to expand further into Europe and are exploring possibilities in Belgium and Holland on top of our existing partnerships in Denmark, Germany and across the UK.

“If growth continues at this pace, we will be looking to take on more staff in 2020 and, most importantly, continuing to provide our clients with the safest, highest-quality service possible.”

Previously a roofer and tower crane operator, Ben founded BGB Scaffolding in 2007 and has led the business to become one of the country’s leading independent scaffolding firms with an emphasis on health and safety in the workplace.

Eighteen of his team are GWO (Global Wind Organisation) and HUET (Helicopter Underwater Escape Training) qualified, a selling point which has enabled them to clock up tens of thousands of person hours without a single Lost Time Injury.

“Since day one my attitude towards the customer and the health and safety of my team has never changed – they are paramount and at the heart of every decision,” said Ben.

“We keep learning, keep working hard and won’t ever take that for granted.

“To win such a prestigious award brings that into focus, so thank you again to the judges for this accolade.”

Irfan Younis CEO of the Awards’ organisers Creative Oceanic added: “Congratulations to all winners and finalists. We salute you for all you do to create jobs, service your industry and the Welsh economy.

“We’re excited to see how the SME campaign evolves over the coming years.”

The North Yorkshire based specialists Acorn, provided scaffolding services to housebuilders and the events sector. Past projects included the awarding-winning ‘Steel Yard‘ structure used at Creamfields.

Howard Smith and David Costley-Wood from KPMG’s Restructuring practice were appointed as joint administrators to Acorn Scaffolding (Yorkshire) Ltd on 2 December 2019.

According to a statement seen by ScaffMag, Acorn had absorbed the impact of several key customers’ entering administration, the company was unable to withstand cash flow pressures resulting in insufficient working capital to trade through the quieter winter season.

As a result the company’s directors took the necessary steps to place the company into administration.

Upon their appointment, the administrators concluded a sale of the business and the majority of its assets to Acorn Construction (Yorkshire) Ltd, a connected party.

As a result of this transaction, a total of 132 employees were transferred to the purchaser under TUPE regulations.

Howard Smith, associate partner at KPMG and joint administrator, said: “The company’s directors explored all avenues before reluctantly placing the business into administration. However, the sale secures a future for the business in Yorkshire and saves jobs in the region.”