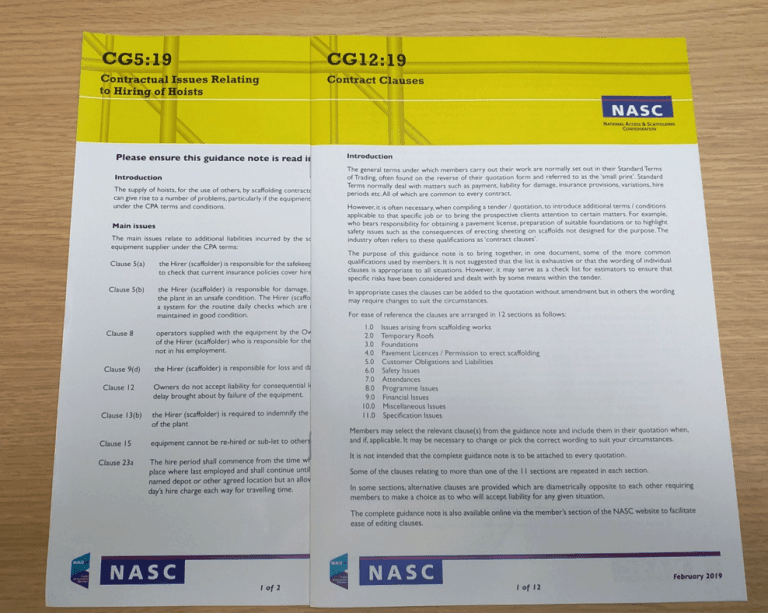

Scaffolding Association to hold Contract Law seminar

The UK’s largest trade body joins forces with specialist solicitors to hold a Contract Law seminar in the capital.

Following feedback from the Scaffolding Association’s (SA) members, the trade body has partnered up with law firm Birketts LLP Solicitors which is one of the largest specialist Construction and Engineering teams outside of London. The Duo will be running a half-day seminar on Contract Law and relevant contract issues called ‘How not to make a rod for your own back…’ The event will take place on Thursday 28th March 2019 from 10am to 3pm and includes lunch, with bacon rolls on arrival from 9.30am. The SA have said places are limited to 25 on a first come first served basis. There is a small charge for the event and discount for members of the Scaffolding Association. Topics will include:- Knowing your contract – what to look out for and the risks if you don’t

- How much control do you have?

- Payment notices – the payment scheme and how it applies to you.

- Variations/changes – risk management, fixed-price contracts etc.

- What happens if you don’t get paid? – suspending your works or termination.

- Dispute resolution – adjudication and insolvency.

- Real life examples will be used.

- Open panel discussion at the end.

Recent incidents lead HSE to issue reminder on scaffolding safety

Storm Gareth has battered the UK with high winds over the last few days leading to the collapse of a number of scaffolds.

A SECTION of sheeted scaffolding around 200 square meters, fell opposite the Royal Free Hospital in North London on Thursday last week. While on Saturday in Kensington another section of scaffolding collapsed onto parked cars narrowly missing pedestrians.

The Scaffold Checklist produced by the HSE is intended to clarify when a scaffold design is required and what level of training and competence those erecting, dismantling, altering, inspecting and supervising scaffolding operations are expected to have. It states that ‘it is the scaffold users/hirers responsibility to ensure that all scaffolding has been inspected following any circumstances liable to jeopardise the safety of the installation, e.g. high winds. All scaffolding inspection should be carried out by a competent person whose combination of knowledge, training and experience is appropriate for the type and complexity of the scaffold,’Ensure your scaffolding is stable and safe: follow our scaffold design checklist at https://t.co/5WrQSNRZz8 pic.twitter.com/7yqYQuxx6A

— HSE (@H_S_E) March 11, 2019

Introducing the new TRAD MINI CATCHFAN

The TRAD Mini Catchfan is a new innovation from TRAD Safety Systems.

This unique system has been specifically designed with the scaffolding sector in mind. The TRAD Mini Catchfan offers significantly increased protection when it comes to the containment of falling objects over that of a traditional boarded fan during the erection and dismantling of a scaffold. The TRAD Mini Catchfan consists of a 100x100mm net with a 20x20mm net overlay which gives the product energy absorbing properties. The systems designed to catch falling objects rather than deflect them back into the building. Furthermore, the fan can be raised up the building so you can keep the protection as close as possible to the working area. What makes the TRAD Mini Catchfan unlike any other safety net fan product on the market is that a crane is NOT required for its installation, or to move it up the building – it can all be done manually. It is often the case that when fans are required, the crane is no longer on site. Additionally, the TRAD Mini Catchfan connects to the scaffold ledger rather than the standards meaning no adaptions are required to the scaffold to make it fit.

Benefits & Features

· Lightweight fully aluminum design allowing each unit to be installed and moved up manually. · High Strength · Lockable for transport · Fitted without tools · Adjustable rail location Pre-marked rail for easy assembly · No loose parts · Fully Tested · Adjustable lower claw · Suits tube Ø48.3 · The system is specifically designed for the containment of falling objects during the erection and dismantling of a scaffold. The fan is tested to catch a 28kg weight falling through 4m · The net element consists of a 100x100mm net with a 20x20mm net overlay for smaller objects · Each fan is 3m in length and projects from the scaffold 2m · Connects to the ledger with scaffold claws · Can be pulled in flush to the scaffold · Full technical support and training available For more information please visit: https://tradsafetysystems.co.uk/product-range/fall-protection/trad-mini-catch-fanDigital Technology Solution From PERI For The Industrial Environment

PERI has combined digital technology with their PERI UP scaffolding solution to help provide seamless operations and greater control for contractors on industrial construction sites.

Digital Technology is rapidly becoming an integral part of the construction industry. Enabling construction projects to have more efficient, cost-effective, plans, designs, and management. PERI’s latest development is an integrated scaffolding programme which reinforces the entire construction process from start to finish, ensuring scaffolding operations are included in the overall planning stages. When planning a project, contractors are able to integrate there own pre-designed 3D models, helping to visualize the prospective scaffolding concept and how it will relate to the site environment and construction process. With this detailed planning in mind, PERI is able to offer clients accurate cost estimates including a list of materials and the cost of labor. PERI PATH software also features in this new technology, providing accurate progress reports, improving forecasts and fine-tuning operations for optimum results. In particular, the simple documentation of targets and actual deviations ensure any correction needed are made promptly to avoid any unnecessary cost. This will be increasingly beneficial on industrial projects which often carry a unique design and maintenance requirements. As well as The Integrated Scaffolding Programme, PERI also supports workers with professional product training courses. The courses are delivered by PERI’s own qualified trainers and assessors. By accessing the correct training the PERI UP scaffold system can be used safely and efficiently from the very beginning of a project. PERI is exhibiting the integrated scaffolding programme at Bauma 2019 where you can experience how performance on site can be improved by this product.Major Scaffolding Collapse in North London

A large section of scaffolding has collapsed onto a street in North West London.

A scaffold collapse has left a mass of bent and twisted scaffold tubes and broken boards on a street in Hampstead, London. The section was attached to a block of flats opposite the Royal Free Hospital. According to local media reports, it fell this afternoon at around 14:50 GMT during high winds. A spokesperson from London Ambulance Service said no injuries had yet been reported, but this could change. The Health and Safety Executive has been informed. The Royal Free Hospital said it was on standby following the collapse but it had not yet been required to treat any patients in connection with it. https://www.facebook.com/sara.mouhoun/videos/10156035350522724/UzpfSTY1MzM0NjIzODoyNDM2MTM5Nzg5NzM5OTYw/?hc_ref=ARRzGqDEyt57SH7BFXuXWwwmOCwl0CEHBPq4mk44zoDlUX81qNy9_3Bruxn4-XFoqII Although unconfirmed one local newspaper the Hamstead Highgate Express has reported that ALB Scaffolding erected the scaffold and spoke to a member of staff who could not say how it happened, but admitted to the paper: “It could well have just been the wind, because it will have caught the plastic sheeting and that can give it nowhere to go.”Layher UK expands with new West Bromwich depot

The worlds largest system scaffolding manufacturer has opened a new depot in the West Midlands.

Layher UK’s head office, in Letchworth, is backed-up by a network of regional depots, the latest is now opening its doors in West Bromwich. The new depot, near Birmingham, puts Layher’s range of equipment and expertise right in the centre of England for the first time. It will provide both a storage and demonstration facility to support Layher’s local clients and to additionally promote their growth in the area. Layher UK says the site’s location, adjacent to the M5 enables unprecedented access via the region’s motorway network including the M6 and M42 motorways to the north and west and M6 and M42 routes to the east, with the M5 also allowing quicker access to the southwest and Wales. This means the new depot not only enables Layher UK to demonstrate their equipment but also to transport it more quickly to its customers within the regions. Experienced at working with Layher Allround materials for many years, Steve Pickard, Layher UK Operations Manager and his colleague Andy Gee, Area Sales Manager are well versed in Layher’s design characteristics and the solutions that it enables. Under the management of Steve and the team, Layher’s well renowned and full added value service package will be fully accessible to all its clients. Sean Pike, Managing Director of Layher Ltd.’s UK office said: “We have always taken the view that our customers’ decision to utilise our modular scaffolding and access and protection systems is not based solely on proven designs, safety and performance, but also on the ability to access a full range of support services at a local level. Our growing depot network demonstrates this with the new facility in West Bromwich adding to our operations in Eggborough near Doncaster, Livingston in Scotland and Dublin in Ireland.”Corporate video goes wrong but scaffolding firm benefits

Funny outtakes from a scaffolding company’s promotional video have become their actual corporate film, and users of Linkedin love it!

The humorous video posted yesterday on Linkedin shows both LA Scaffolding’s Managing Director Gary Sadler and Senior Contracts Manager Brett Lambert keeping it ‘real’ seems to of struck a chord with users of the business orientated social media site. In just 24 hours the video has already racked up nearly 5,500 likes and over 1000 comments of congratulations. The video came about after Leeds based LA Scaffolding recently enlisted a marketing company to create a new website and a serious corporate video, however, things didn’t go entirely to plan while filming. LA Scaffolding’s Managing Director Gary Sadler originally wanted to create a film that captured what they are about and how they are really customer service focused. What actually happened can be seen in the film above. “We had the site built and tried to make a “corporate” video, we ended up with a lot of out-takes and laughing a lot, we thought that this captures us better than any corporate video could.”, Sadler wrote on Linkedin. Speaking to ScaffMag about the video, Sadler told me: “I’ve got to give a shout-out to Wayne at Digital Growth Secrets as we’ve been working with them on a new website and marketing campaign. We were making our own version of a ‘corporate’-ish style video and to be honest it wasn’t going to plan, we were all laughing too much and we just didn’t know how to be all ‘corporate’, he convinced me that we should use the outtakes as they were so funny and it’s taken on a whole new life of its own, as a lot of people seem to agree.” He added: “We seem to have struck a genuine chord with people who are sick of the fake stuff that’s out there and had a real laugh along the way. I think we sometimes as scaffolders we get overlooked, but I’d say we have a real input on the success of construction projects, at least people know we have a good sense of humor now!”Firm fined after scaffolding collapses at school

A scaffolding company has been fined over £24K after scaffolding they had erected collapsed onto a neighbouring primary school.

Scaffolders from Swain Scaffolding had erected a 7m high gable end scaffold on a residential property in Penarth, Vale of Glamorgan. Cardiff Magistrates’ Court heard that on 5 May 2017 at around 1:30pm, the scaffold collapsed onto a single storey roof above the playground of a neighbouring school. Shockingly at the same time, a group of young children was playing just meters away from the collapse, while just minutes before, the playground had been full of schoolchildren on their lunch break. An investigation by the Health and Safety Executive (HSE) found the scaffolding was not designed or installed to withstand foreseeable loads. It was not tied to the adjacent building, nor did it have adequate buttressing or rakers and was essentially a freestanding structure. The investigation found that it was almost inevitable that the scaffolding would collapse, even in unremarkable weather conditions. Swain Scaffolding Limited based in Cardiff was found guilty of breaching the Construction Design and Management Regulations and was fined £24,000 and ordered to pay £3452.50 in costs. Speaking after the hearing, HSE inspector Gemma Pavey commented: “Failure to adequately design and install scaffolding, so that it can withstand foreseeable loads, creates risk to workers and members of the public who could be injured by an uncontrolled collapse. “Companies should be aware that HSE will not hesitate to take appropriate enforcement action against those that fall below the required standards.”Safety and Access expands training reach into west London

Scaffolding training providers Safety and Access has today unveiled the opening of a brand new CISRS Accredited Scaffolding Training facility in London.

The new facility is part of the West London College Campus which is conveniently located at Park Royal – the largest business park in the capital. It’s been set up as part of a construction related learning venture that also features a flurry of other trades including joinery and electrical training.

Strategically located for positive transport links and within easy reach of local tube and bus routes, the new scaffolding training facility includes excellent welfare and catering facilities, Safety and Access said.The training company will be offering the following scheduled courses to its customers with immediate effect:

- CISRS Basic Scaffolding Inspection

- CISRS COTS New Entrant Course

- CISRS scaffolding Manager and Supervisor Course.

- CISRS scaffolding Manager and Supervisor Course. (Refresher)

- Scaffolding Appreciation

- SG4 / TG20 Appreciation Course

Safety and Access also say, there are plans to introduce CISRS Scaffolder CPD Course, CISRS System Scaffolding Course and PASMA training to the facility in the coming weeks.

Rick Statham (Joint MD for Safety and Access) commented. “We are extremely happy to finally have a permanent presence in the capital to support our clients. We have been planning this move for almost two years and we believe we have got this model right and can help to meet some of the demand in the region”

Dave Mosley (Scheme Manager for CISRS) added; “it’s is good to see that providers are willing to expand their services to meet the demand for training in different regions. There has previously been no CISRS provision in the West of London so I’m hoping this will make it easier for those in the surrounding to attend CISRS training.

For more details please visit the Safety and Access website www.safetyaccess.co.uk