A leading Plymouth supplier of shrink-wrap sheeting has completed a world first project. Using their latest product to market, Tufcoat Wraphix™ Printed Shrink-wrap, Tufcoat has broken new ground.

In combining digital printing with 300µm flame retardent scaffold shrink-wrap. Now, for the first time, contractors and subcontractors can have images and logos printed directly on to projects, whilst still benefiting from both weather protection and encapsulation.

The company worked with Westward Housing and JEM Scaffolding to weatherproof Plymouth House, ensuring 70 vulnerable people can remain in residence whilst the £1m refurbishment takes place. Due to excellent visibility both contractors and client saw this as the perfect opportunity to use the Printed Shrink-wrap promoting all of the various companies involved. The result was greater brand awareness, something shrink-wrap hasn’t been able to achieve previously. Following the success of the project, Carlo Cinque of Westward Housing Group said: “The end result was actually better than we had imagined. We’ve had major contractors come to us since and ask about who supplied us with the printed wrap”.

The product allows its customers regular practicality and function, but it’s also created using low-density polyethylene, less harmful for the environment than PVC or mesh wrapping. By choosing Wraphix™, projects can be protected against adverse weather, provide environmental containment and display any marketing message on a single sheet.

Richard Barnes, Operations Director of Jem Scaffolding explained “I think the actual two weeks they had to install was reduced down to about six days. So we put them under a great deal of pressure with a product that they hadn’t used regularly, and they really stole the show with what they produced in the end. We’ve had lots of comments from the media and through social media, so it’s worked well for us.”

Tufcoat’s innovative new product has also been installed on the prestigious Grosvenor House, a JW Marriott hotel in London. Marking a significant creative challenge from the previous project, their task was to recreate a photo-realistic representation of the building’s façade, using the same prime printed 300µm flame retardant shrink-wrap.

The firm encapsulated the 500 square metre scaffolding and hoist, and combined the building design used on the printed wrap with typical shrink-wrap. Because of this, Tufcoat were able to considerately minimise the impact of the works during renovations to some of the hotel’s 496 rooms and suites. A high level of the aesthetics was retained as a consequence. And of course, there was the added benefit of weather protection for the workforce in line with the clients brief.

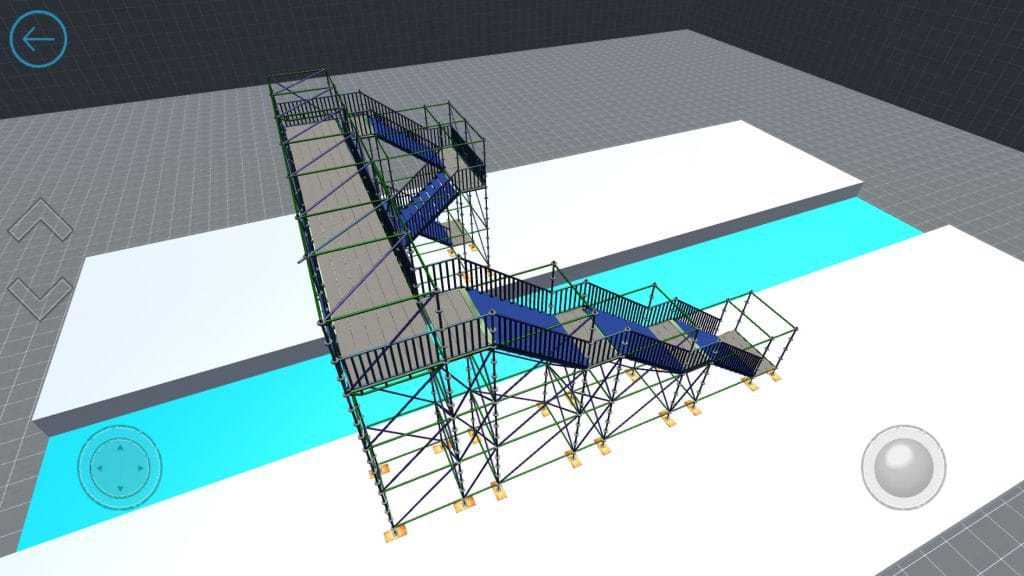

Once a bid is won and users are ready to finalize the scaffolding, they can virtually travel through the structure and identify potential hazards (such as obstructions), which helps them create a safe work plan. Users can thoroughly familiarize crews with the project, so that they can safely hit the ground running. Then, at the job site, crews can access 2D and 3D drawings on any mobile device, or inspect the job virtually through a smartphone and a VR viewer.

Scaffold VR is already developing a following. “VR is a great application. I’m loving the VR,” tweeted Mark Parkin of Tiger Scaffolding in Whitby.

Anyone using an iPhone or Android smartphone or tablet, or a Windows desktop can try Scaffold VR for free, just search for “Scaffold VR” in your app store, download and install it. The app comes with sample drawings that provide the 3D experience. However, the combination of Scaffold VR, a smartphone and the Scaffold VR Cardboard Viewer, enables an immersive virtual reality experience that creates a lasting impression.

Along with the release of Scaffold VR, Avontus offers low-cost, custom cardboards with QR codes that point directly to the app on the Google Play and Apple App stores. Users can buy the cardboards through Amazon and ship directly to their customers who can then easily experience their scaffolds in virtual reality.

Virtual reality adds a richer experience to scaffold designs and helps companies work more efficiently. Scaffold VR can change the way projects are planned, presented, and built.

Once a bid is won and users are ready to finalize the scaffolding, they can virtually travel through the structure and identify potential hazards (such as obstructions), which helps them create a safe work plan. Users can thoroughly familiarize crews with the project, so that they can safely hit the ground running. Then, at the job site, crews can access 2D and 3D drawings on any mobile device, or inspect the job virtually through a smartphone and a VR viewer.

Scaffold VR is already developing a following. “VR is a great application. I’m loving the VR,” tweeted Mark Parkin of Tiger Scaffolding in Whitby.

Anyone using an iPhone or Android smartphone or tablet, or a Windows desktop can try Scaffold VR for free, just search for “Scaffold VR” in your app store, download and install it. The app comes with sample drawings that provide the 3D experience. However, the combination of Scaffold VR, a smartphone and the Scaffold VR Cardboard Viewer, enables an immersive virtual reality experience that creates a lasting impression.

Along with the release of Scaffold VR, Avontus offers low-cost, custom cardboards with QR codes that point directly to the app on the Google Play and Apple App stores. Users can buy the cardboards through Amazon and ship directly to their customers who can then easily experience their scaffolds in virtual reality.

Virtual reality adds a richer experience to scaffold designs and helps companies work more efficiently. Scaffold VR can change the way projects are planned, presented, and built.

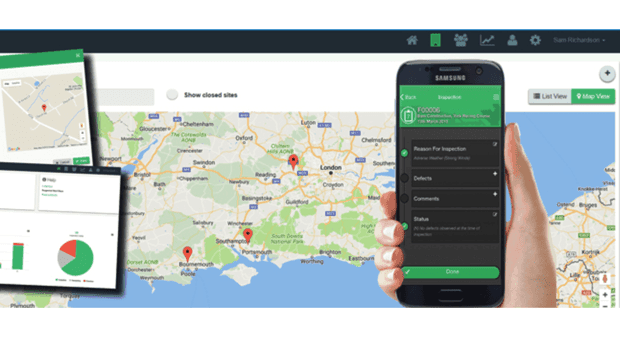

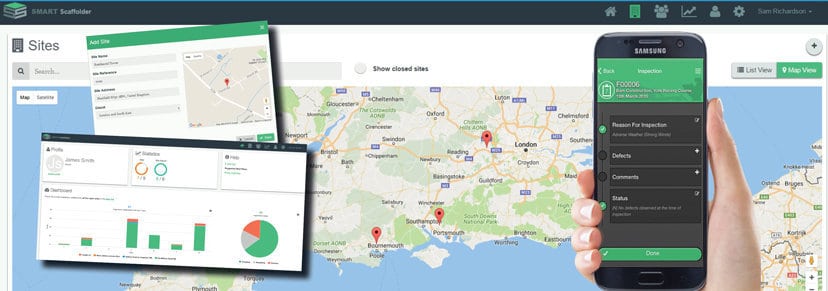

SMART Scaffolder say the SMART Inspector app enables the user to store all inspection records online which can be easily retrieved back at the office via a simple separate desktop console. This prevents the build up of unnecessary inspection paper copies and retyping out onto an office computer.

A spokesperson for SMART Scaffolder said: “Carrying out an inspection couldn’t be simpler: just set up the site on the desktop console and then follow the steps on the app when you’re onsite. You can capture photos of any defects you find and you record the client’s signature on your phone.”

“The desktop console makes it easy to bring up reports such as unsafe scaffolds, completed inspections, inspection history and, coming very soon, handover certificates and scaffolds on extra hire.”

You can find out more about this new app and arrange a free trial by visiting

SMART Scaffolder say the SMART Inspector app enables the user to store all inspection records online which can be easily retrieved back at the office via a simple separate desktop console. This prevents the build up of unnecessary inspection paper copies and retyping out onto an office computer.

A spokesperson for SMART Scaffolder said: “Carrying out an inspection couldn’t be simpler: just set up the site on the desktop console and then follow the steps on the app when you’re onsite. You can capture photos of any defects you find and you record the client’s signature on your phone.”

“The desktop console makes it easy to bring up reports such as unsafe scaffolds, completed inspections, inspection history and, coming very soon, handover certificates and scaffolds on extra hire.”

You can find out more about this new app and arrange a free trial by visiting

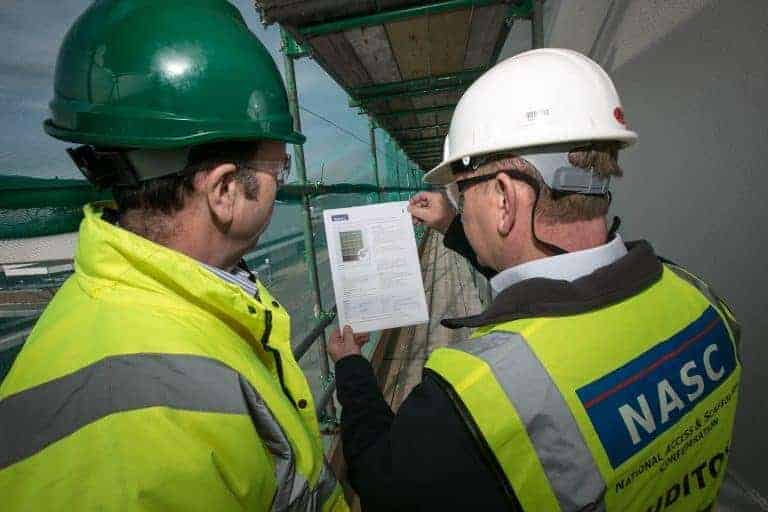

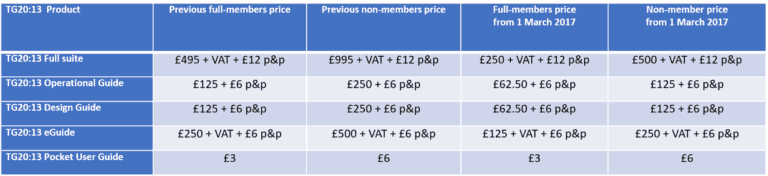

The aforementioned meetings were held in September and November of 2016, they were setup to review feedback and agree on modifications and amendments to TG20:13 in time for the next TG20:13 revision.

The NASC invited and received a considerable amount of feedback on the guidance, from member companies and non member purchasers of TG20:13, outlining what they would like to see incorporated in the next revision.

The NASC say some of the suggestions received included, ‘varying the number of boarded lifts, production of basic drawings and calculations, and increased leg load information’.

An eGuide software upgrade is expected to be issued free of charge in the spring of 2017, however the NASC say the timescale for full review has not been agreed. It is unlikely that a fully updated version of TG20 will be published for at least two years.

The aforementioned meetings were held in September and November of 2016, they were setup to review feedback and agree on modifications and amendments to TG20:13 in time for the next TG20:13 revision.

The NASC invited and received a considerable amount of feedback on the guidance, from member companies and non member purchasers of TG20:13, outlining what they would like to see incorporated in the next revision.

The NASC say some of the suggestions received included, ‘varying the number of boarded lifts, production of basic drawings and calculations, and increased leg load information’.

An eGuide software upgrade is expected to be issued free of charge in the spring of 2017, however the NASC say the timescale for full review has not been agreed. It is unlikely that a fully updated version of TG20 will be published for at least two years.

Chaired by Mike Palmer – Regional Quality, health, safety,

environment and Training Manager at Rapid Access; the Panel comprises industry experts from a wide range of backgrounds and experiences with the common objective of advancing safety and good practice through standards, guidance and training.

Mike said: “We all have first-hand experience of working in the region and therefore know and understand the way in which the local access industry operates. We want to offer insight and advice and to encourage a good practice mindset based on accepted standards and skill.”

Sarah Nunn, PASMA’s Head of International Development, is delighted with the positive response that the Panel is already receiving. “Here at PASMA we are passionate about making work at height safer for everyone. The launch of the Panel is a practical demonstration of that commitment to reducing falls from height.”

Chaired by Mike Palmer – Regional Quality, health, safety,

environment and Training Manager at Rapid Access; the Panel comprises industry experts from a wide range of backgrounds and experiences with the common objective of advancing safety and good practice through standards, guidance and training.

Mike said: “We all have first-hand experience of working in the region and therefore know and understand the way in which the local access industry operates. We want to offer insight and advice and to encourage a good practice mindset based on accepted standards and skill.”

Sarah Nunn, PASMA’s Head of International Development, is delighted with the positive response that the Panel is already receiving. “Here at PASMA we are passionate about making work at height safer for everyone. The launch of the Panel is a practical demonstration of that commitment to reducing falls from height.”