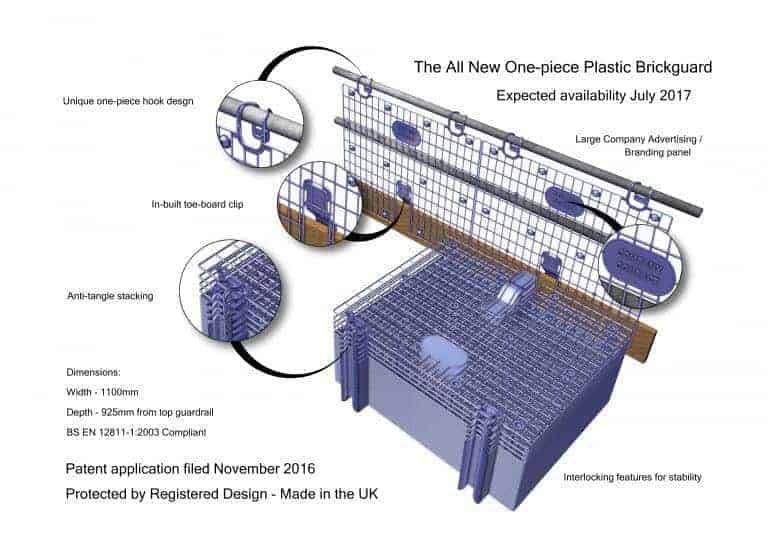

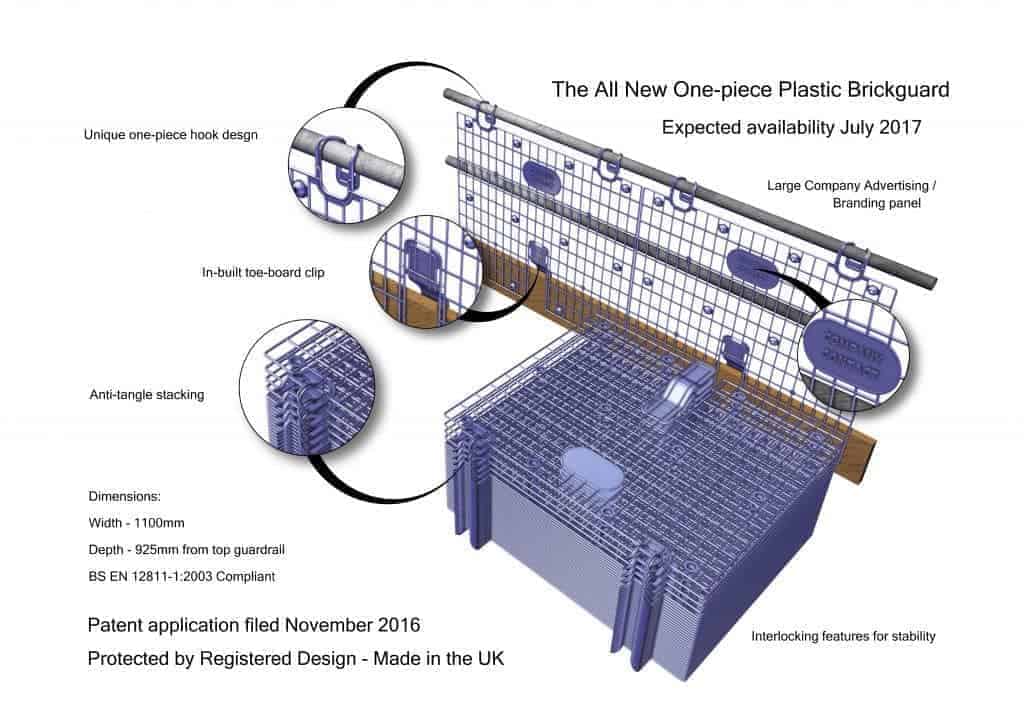

Max Scaffold Products (MAX SP) adds a new wider One-piece Plastic Brickguard to its product line after production gets the green light.

The Oxfordshire based company behind the successfully popular MAX One-piece Plastic Brickguard is in the production phase of creating a new brick guard. The initial design will remain the same in principle to the original, however the new design will benefit from a wider dimension (1100mm). The new brickguard also features a traditional speedier hook type design, that works with tube and fitting and system scaffolding products like Haki.

According to MAX SP, The All New One-piece Plastic Brickguard is expected to be available from July this year.

The original MAX One-piece Brickguard was launched back in 2012, it was widely accepted within the industry as a revolutionary product, after it relieved the pain for many scaffolding firms from using the metal variant, which in short, was a total nightmare to install for scaffolders.

“The original brickguard will still be in production but this new brickguard will give the end user more choice when choosing their brickguard” says Peter Westlake of MAX Scaffold Products.

“The main difference between the two is the unique one-piece hook design which has a more traditional feel to it and being an ex-scaffolder I have to admit I like brickguard’s that just drop over the guardrail for speed.”

“All the other features are the same in principle if not in design. They stack vertically, the spacing domes provide stability, the toe board clip reduces the need for additional fixings and the hooks fit inside each other without tangling.” Peter added.

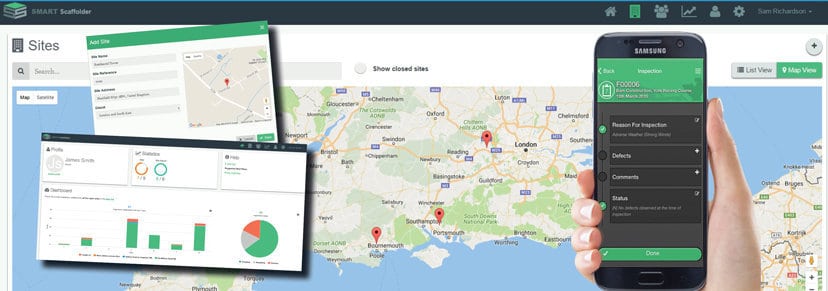

SMART Scaffolder say the SMART Inspector app enables the user to store all inspection records online which can be easily retrieved back at the office via a simple separate desktop console. This prevents the build up of unnecessary inspection paper copies and retyping out onto an office computer.

A spokesperson for SMART Scaffolder said: “Carrying out an inspection couldn’t be simpler: just set up the site on the desktop console and then follow the steps on the app when you’re onsite. You can capture photos of any defects you find and you record the client’s signature on your phone.”

“The desktop console makes it easy to bring up reports such as unsafe scaffolds, completed inspections, inspection history and, coming very soon, handover certificates and scaffolds on extra hire.”

You can find out more about this new app and arrange a free trial by visiting

SMART Scaffolder say the SMART Inspector app enables the user to store all inspection records online which can be easily retrieved back at the office via a simple separate desktop console. This prevents the build up of unnecessary inspection paper copies and retyping out onto an office computer.

A spokesperson for SMART Scaffolder said: “Carrying out an inspection couldn’t be simpler: just set up the site on the desktop console and then follow the steps on the app when you’re onsite. You can capture photos of any defects you find and you record the client’s signature on your phone.”

“The desktop console makes it easy to bring up reports such as unsafe scaffolds, completed inspections, inspection history and, coming very soon, handover certificates and scaffolds on extra hire.”

You can find out more about this new app and arrange a free trial by visiting

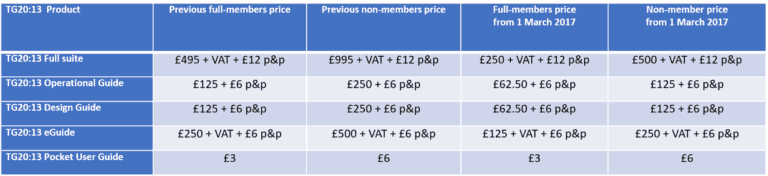

The aforementioned meetings were held in September and November of 2016, they were setup to review feedback and agree on modifications and amendments to TG20:13 in time for the next TG20:13 revision.

The NASC invited and received a considerable amount of feedback on the guidance, from member companies and non member purchasers of TG20:13, outlining what they would like to see incorporated in the next revision.

The NASC say some of the suggestions received included, ‘varying the number of boarded lifts, production of basic drawings and calculations, and increased leg load information’.

An eGuide software upgrade is expected to be issued free of charge in the spring of 2017, however the NASC say the timescale for full review has not been agreed. It is unlikely that a fully updated version of TG20 will be published for at least two years.

The aforementioned meetings were held in September and November of 2016, they were setup to review feedback and agree on modifications and amendments to TG20:13 in time for the next TG20:13 revision.

The NASC invited and received a considerable amount of feedback on the guidance, from member companies and non member purchasers of TG20:13, outlining what they would like to see incorporated in the next revision.

The NASC say some of the suggestions received included, ‘varying the number of boarded lifts, production of basic drawings and calculations, and increased leg load information’.

An eGuide software upgrade is expected to be issued free of charge in the spring of 2017, however the NASC say the timescale for full review has not been agreed. It is unlikely that a fully updated version of TG20 will be published for at least two years.

Chaired by Mike Palmer – Regional Quality, health, safety,

environment and Training Manager at Rapid Access; the Panel comprises industry experts from a wide range of backgrounds and experiences with the common objective of advancing safety and good practice through standards, guidance and training.

Mike said: “We all have first-hand experience of working in the region and therefore know and understand the way in which the local access industry operates. We want to offer insight and advice and to encourage a good practice mindset based on accepted standards and skill.”

Sarah Nunn, PASMA’s Head of International Development, is delighted with the positive response that the Panel is already receiving. “Here at PASMA we are passionate about making work at height safer for everyone. The launch of the Panel is a practical demonstration of that commitment to reducing falls from height.”

Chaired by Mike Palmer – Regional Quality, health, safety,

environment and Training Manager at Rapid Access; the Panel comprises industry experts from a wide range of backgrounds and experiences with the common objective of advancing safety and good practice through standards, guidance and training.

Mike said: “We all have first-hand experience of working in the region and therefore know and understand the way in which the local access industry operates. We want to offer insight and advice and to encourage a good practice mindset based on accepted standards and skill.”

Sarah Nunn, PASMA’s Head of International Development, is delighted with the positive response that the Panel is already receiving. “Here at PASMA we are passionate about making work at height safer for everyone. The launch of the Panel is a practical demonstration of that commitment to reducing falls from height.”