Cape Plc Continue To Be Committed To Overseas Training

ScaffMag gains further insight into overseas training after meeting with Cape Plc in the Middle East.

Continuing with my investigation into the effectiveness of the UK scaffolding training schemes while in the Middle East I managed to share some time with Paul Grant, the Head of Scaffolding In The Kingdom Of Saudi Arabia for Cape RB Hilton. Speaking with Paul in Al Jubail, Saudi Arabia I quickly realised Cape Plc are incredibly committed to ensuring that their greatest asset: the people within the business are trained and developed to the highest levels possible to provide their clients with operational excellence. In the Gulf Region Cape Plc and its subsidiaries are one of the biggest employers of Scaffolders. Currently employing a workforce of over 6,000 in various scaffold related roles. Paul commented: “The development of our people and our teams is the key to our success within the scaffolding sector. We have seen good growth due to our ability to provide, quality equipment and products delivered by a skilled and professional team. Training is the key to our continued growth in the Region. ‘We will not train people for the sake of training, any Training we provide will be specific to our business plans and will enhance our ability to deliver to our clients and stakeholders.” “We recognise that the key to increased productivity in our business will come from having high performing Scaffolders qualified to UK and International standards that have been trained to the highest levels in regard to health and safety possible. We are also seeing many of our international and regional clients looking towards UK based accredited skills schemes to prove and demonstrate competency.” “At Cape we have had a vigorous training regime for some time with schemes such as the CITB NVQ Route as well as CISRS, being in place, across the Region. However some of the existing Training courses that are available need to be tailored to suit the regional requirements of our business and those of our clients.”NASC Release Update For TG20:13

The NASC announce a free update for TG20:13 and eGuide.

The National Access And Scaffolding Confederation (NASC) has updated its TG20:13 good practice guidance for tube and fitting scaffolding with a new document entitled Supplement 1. The document is available as a free download from the NASC website as a PDF and is accompanied by an eGuide software update entitled Version 1.1. Principal features of the update are as follows: A specification for TG20:13 compliant 3.2mm wall thickness cold-formed high tensile steel tubes to BS EN 10219-1; An amendment to the sign off section of compliance sheets to state that illustrations are indicative; Clarification regarding ties to the inner face of the scaffold only; Compliance sheets for sheeted scaffolds with transom units; Compliance sheets for scaffolds of 2.0m, 3.0m or 4.0m height; Clarification regarding the horizontal spacing of ties for scaffolds with a maximum bay length less than 2.0m. Terry Roberts of CADS (technical authors of TG20:13) said: “The NASC recommends that compliance sheets from the new eGuide are always used. However, the update has been designed in such a way that compliance sheets from the original eGuide (and from the TG20:13 Operational Guide) remain valid, so there is no need to differentiate between new and original compliance sheets on site.” Robin James, NASC Managing Director added: “These updates to TG20:13 demonstrates the commitment of the NASC to the continual improvement of TG20:13 to meet the demands of the UK scaffolding industry. The NASC advises that all existing users of TG20:13 should download this new version of the TG20:13 eGuide together with the accompanying document Supplement 1.”PROMOTION: Scaffolding Part 1 Tube and Fitting at WATA 10% Discount

Scaffolding Part 1 Tube and Fitting at WATA 10% Discount

Only £783 + VAT for the 6th October

Promotional code S1M17

On successful completion candidates will gain the CISRS Scaffolding Part 1 certificate

Special Report: Making ‘The’ Difference In The Middle East.

Simian Skill’s GCC Manager Terry Sennett and his team of instructors are on a crusade to educate and ultimately save lives in the Middle East.

Currently the world’s eyes are firmly focused on the the GCC (Gulf Cooperation Council for the Arab States) after mounting criticism from many human rights groups over the high migrant worker mortality rates and very low safety standards within the GCC construction industry.These groups are steadily putting huge amounts of pressure on the region to cut fatalities and injuries by raising safety standards.

For years in the Middle East many scaffolding industry personnel have obtained certificates of competence after merely watching a video or a Power Point presentation. With this shocking fact in mind many businesses and the workers themselves are now beginning to ‘wake up’ and understand the imperative need for specific industry training from professionally qualified experts.

I travelled to the Middle East to interview key industry leaders and investigated the introduction and effectiveness of the UK scaffolding training schemes in the region. Simian Skill is one such UK training organisation that is making substantial progress in the GCC.

Eight months ago Simian Risk employed the skills and expertise of Terry and Fiona Sennett to help raise safety standards and expand the Simian Skill business in the GCC region. In that time they have had fantastic positive results and have just recently quadrupled sales and uptake. However the Simian Skill GCC operation is not a business model of just churning out training to clients for profit they are doing something different. When I say ‘different’ I mean…revolutionary!

A week in the life of Terry Sennett, GCC Manager, Simian Skill

The renowned scaffolding expert that is Terry Sennett, Simian Skill’s GCC Manager, was my guide for the week as we traveled thousands of miles in the GCC covering three countries in five days. By his side I gained unlimited access into the inner workings of Simian Skill’s operation in the Middle East.

Terry’s passion and drive sits firmly with training and education, he now wants to pass on his extensive expert scaffolding and design knowledge, after he and his wife built up two very successful scaffolding companies back in Southampton, UK.

After spending a short space of time with Terry I was able to understand his charismatic charm and infectious passion, He has an incredible dedicated drive to educate others by challenging the norm and pioneering new ways for scaffolding training. No more is he willing to continue with the same old ‘death by powerpoint presentations’ that we have here in the UK, but to embrace new teaching techniques that marry with 21st century technology.

Terry has big ambitions and plans to write new innovative first of it’s kind training courses and to continue to expand Simian’s operation in all six GCC countries. However with only 150+ registered scaffolding instructors in the UK, shortages in skilled passionate instructors will be inevitable.

ScaffMag Interview: “Terry in our last interview back in December 2013 you mentioned that in the UK, scaffolder training courses elements were missing, How are you addressing these missing elements in the GCC ?”

Terry Sennett said:

“Yes I remember this point well and it was one of my first priorities, to tackle on my arrival in the GCC region, back in early January of this year.”

“During my time in the UK Training Centres both as a delegate and Instructor, I had to sit through Supervisor Courses that bore no relevance to, or taught the vital skills required, for the modern day industry Supervisor/Contracts Manager. Including exercises such as calculating Tube and Coupler materials free hand and job pricing strategies, using historical 30-year old methodology and techniques, long since dispensed with by the industry. Attempting to scale off dimensions from poorly created design drawings, that didn’t actually scale. Irrelevant scopes of work and projects from yesteryear, used to create inaccurate productive labour resource plans that always seemingly revolved around ‘price works’, which didn’t consider current safe working procedures such as SG4: 10 and its method of compliance.”

“Similarly the generic Risk Assessment and Method Statement exercises undertaken were inaccurate and by and large lacking in vital content. The course was padded out with the inclusion of 1-day from Basic Scaffolding Inspection course and a morning’s marketing/sales visit from a computer software company selling scaffolding estimating packages.”

“I immediately rewrote and restructured this course, adding relevant dynamic practical exercises, regardless of the venue or country it would be delivered within. Relevant standards, safe-working procedures, resource planning amalgamating critical design, build-ability and product materials selection were introduced and underpinned the vital communication process, both up and down the personnel demographic ratios, that exist within all organisations.”

“A huge gap exists within our industry, a void that has not been adequately or efficiently bridged to date.”

“The aforementioned new tasks, processes and procedures all stem from the various content and accuracy of the client’s brief received, which is focused upon in great detail. However those missing elements were not the final extent of what I was referring to back in December 2013! A huge gap exists within our industry, a void that has not been adequately or efficiently bridged to date.”

“I am extremely excited to finally get the long awaited opportunity, to work together again with the hugely talented, innovative and inspirational scaffolding design expert that is Ben Beaumont, of 48.3 Scaffold Design. We have cleared our future diaries and set a date of 13th October 2014, to sit down across a table and collaborate on writing the very first training course of its kind, over a continuous 5-day period.

“This course will bridge the existing gap between Scaffolding operatives, “management” and scaffolding designers. I am sure Ben and myself will be only to pleased to provide ScaffMag with a future in depth exclusive, on what I can assure you this will be a huge step forward for the scaffolding industry’s professional training & educational syllabus.”

Dubai – United Arab Emirates

The cosmopolitan metropolis of Dubai is the business and cultural hub of the Middle East. The city has become world famous with its symbolic record breaking skyline and its extreme construction projects. This awe-inspiring city is also the home of Simian Skill’s Middle Eastern scaffolding training centre.

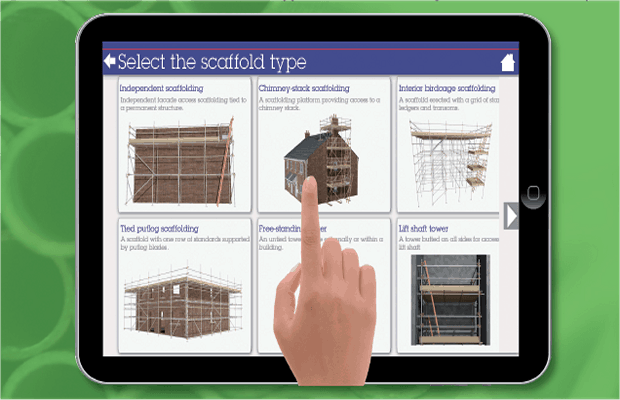

The CISRS accredited training facility offers delegates the opportunity to be trained to the highest possible standards in scaffolding. Unlike other training firms, Simian Skill is able to offer potential clients and contractors three accredited options of training:

CITB Overseas Scaffolder Training Scheme. CISRS Overseas Scaffolder Training Scheme.

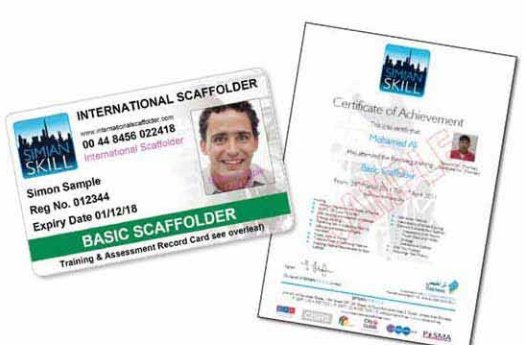

Simian Skill International Scaffolder Training Scheme.

CISRS Overseas Scaffolder Training Scheme.

Simian Skill International Scaffolder Training Scheme.

With Simian’s own reputable accredited training standard The International Scaffolder Scheme (IS) highly trained instructors are able to offer bespoke course content to fulfil a site specific need for clients and employees. This is not possible with the other accredited training options due to the awarding bodies constraints on overseas training.

ScaffMag Interview: “Terry what are the major differences between Simian’s International Scaffolder Training Scheme content compared to what’s being given in the UK ?”

Terry Sennett said: “The International Scaffolder Scheme (IS) provides Simian and myself with the creative freedom, to be innovative with our training content and its delivery. Overseas clients specialise in specific industry areas, such as petrochemical, (oil & gas) construction, facilities management, residential and industrial refurbishment, which is no different from the UK.”

“The International Scaffolder Scheme (IS) provides Simian and myself with the creative freedom, to be innovative”

“The difference within the GCC region is that clients working on offshore installations for example, will not accept rigid, set in stone training course syllabuses, that consist of erecting and dismantling scaffolding structures, that are simply not relevant to the specific works they undertake, as an organisation. I dare say that you do not install many Rolling or Static Temporary Roof structures, within your place of work Dan? How about residential type Chimney Stack configurations, Freestanding Towers and Independents incorporating Buttresses and Kentledge, how about Putlog structures or Timber Frame configurations?”

“Why would your employer or you for that matter, pay to undertake a training course on those elements, if they are irrelevant to your employer’s and your everyday professional undertakings? But employers and scaffolders do every week, month and year in the UK.”

“I believe that the training course contents and approach within some third party accredited schemes, are outdated and irrelevant to today’s versatile and multi skilled scaffolding industry undertakings. No longer do the majority of scaffolders simply work on construction sites or undertake “Street Work.” I also believe that modern day training course syllabuses should begin with a mandatory standardised Basic Level, course, which incorporates far more relevant and in depth content.”

“On successful completion of this initial stage of education, further training courses should then be made available, as individual and specific Modules. Those Modules should be relevant to the particular sector of the scaffolding industry that both employers and employees specialise within.”

“We create bespoke and relevant courses, specific and tailored exactly to our valued clients individual professional requirements. No other training scheme currently provides this flexibility, versatility and above all, relevant and valued solutions to employers and employees alike.”

The Kingdom Of Saudi Arabia

The Kingdom Of Saudi Arabia (KSA) has highly developed industries within its boarders, huge refineries and a abundance of large oil fields litter the country. The KSA has the world’s second largest oil reserves and the world’s sixth largest natural gas reserves.

Simian Skill has recently become the first ever UK based scaffolding training organisation to operate in the KSA. I was fortunate in being able to accompany Terry in the KSA to meet with Simian Skill’s recent client Cape RB Hilton Saudi Arabia.

Simian Skill instructors had just completed delivering some CISRS Basic Scaffold Inspection training for a selection of Cape operatives. Terry with his exacting standards wanted some crucial feedback from the client on how the instructor performed and if any improvements could be made for future training. Paul Grant (Head of Scaffolding at Cape RB Hilton Saudi Arabia) gave the feedback and explained how he was very impressed with the instructing.

Paul also said:

“We have used Simian Skill across the Cape business to enhance our Training Plans and now feel comfortable that we have found an experienced and flexible partner within the Region. Simian will tailor their courses to fit our business needs while maintaining the criteria of the certifying bodies.”

“Nobody knows the game or has a passion for scaffolding like a scaffolder.”

“It is also a great comfort to know that they have experienced ex-scaffolders and Senior Management from the industry conducting the training as well as running the business in the region. They know what we need as a management team and also connect with the guys being trained, nobody knows the game or has a passion for scaffolding like a scaffolder.”

ScaffMag Interview: “Terry you recently announced they had quadrupled attendees & sales in the GCC in the first quarter of 2014. What do you think are the main reasons behind these positive results ?”

Terry Sennett said:

“Ah, that hard and cold unit of measurement, that interests and consumes so many…sales figures!”

“Yes, it is an accurate statement that by the end of the second quarter (June) of 2014, Simian had indeed quadrupled attendees and subsequently sales. Further still, the attendees and sales figures for just the month of August alone, eclipsed the total annual figures in both those areas, for the whole of 2013, isn’t that just fantastic? I believe there are three main reasons for this progress:

1. “All of our valued clients share the same passion, values and principals as their colleagues here at Simian. Our client’s are committed to the same cause as ourselves, which is doing the utmost within our joint capabilities, to ensure all respective workforces receive the very best scaffolding industry training and education, available within the GCC region today.

Simian and our clients both strive to ensure that their workforce/our delegates, all receive the required industry knowledge and skill sets, to enable them to remain safe in their respective professional roles at all times, whilst working in our extremely hazardous industry. This imparted industry knowledge and skill sets delivered through our training, also provide the solution for increased productivity, efficiency and a measurable consistency of performance, which commercially benefits our clients and their clients in turn.”

2. “The Simian team members are all residents of the UAE and have committed their lives to making THE difference for our valued clients in the GCC region. We are a passionate, driven and extremely experienced group, having successfully undertaken every professional role within the UK scaffolding industry.

“I believe clients in the GCC region understand Simian’s core principals and most critically, our cause behind the “Why, How and What” we do passionately as a team.”

We have all lived through the huge industry changes required, to achieve compliancy within the heavily regulated UK scaffolding and access industry. Therefore as a group, we are the very best people to listen intently to our valued client’s industry problems, provide them solutions and thus by working closely together, assisting and supporting them towards achieving their goals, of improving both their respective workforce’s health, safety and commercial performance over time.”

3. “Simian’s training courses differ from the alternatives currently available within the GCC. I have never received a certificate of “competence” for watching a movie at the cinema, or simply watching a Power Point presentation. Simian’s Instructors DO NOT deliver crane operators, earth moving, man-lift, fire fighting, first aid, food safety, catering or any other training courses during the week. Clients and indeed employees in the Middle East are recognising the critical need to receive specific industry training from professionally qualified experts in their particular field of expertise.”

“Over the last 8-months I have noticed a distinct swing away from the multitude of “In house” type scaffolding courses, that one simply has to attend to obtain a certificate of competence. These certificates are effectively worthless regarding demonstrating competency and are poor value despite their low cost, as they expire on an annual basis. I believe clients in the GCC region understand Simian’s core principals and most critically, our cause behind the “Why, How and What” we do passionately as a team.”

SABIC, Saudi Arabia

While in the KSA we also met up with Terry’s colleague and fellow instructor Steve Gregory. Steve had been in the region for the past month providing CISRS Scaffold Inspection training and CISRS Overseas Scaffolding Supervisor courses to operatives at the chemical giant SABIC, which is one of the world’s leading manufacturers of chemicals, fertilisers, plastics and metals.

After navigating through the stringent army/security checkpoints and arriving at the SABIC site I was taken aback at the sheer size of the facility. I was informed by a SABIC official that over 6,000 scaffolders operate on maintenance work just on this one site.

After signing in and handing over our passports in the huge reception area we were led through to the training rooms where Steve Gregory was in the middle of the theory for the CISRS Scaffold Inspection course to 12 delegates. We sat down and listened to Steve’s knowledgeable delivery of the course content. I looked around the room and witnessed how enthralled the mostly Arabic-speaking employees were with Steve’s delivery, taking notes and studying hard.

ScaffMag Interview: “Terry where are Simain’s competitors in the GCC ?”

Terry Sennett said:

“I honestly do not believe we have any competitors, as our service provision is so unlike any other training providers within the GCC region, to draw comparisons against! Of course, I am aware of who the others are within the market place, but they really are irrelevant to us during our daily operations.

We are totally committed and concerned with the task of delivering the very best service provision to our valued clients and their respective workforces. We are always striving to improve ourselves and can absolutely guarantee, that we will be even better in 6-months time. There simply isn’t any need to consider the subject of competitors, as ultimately it is always the clients that decide who your competitors are and will be in the future. I do not wish to appear flippant or indeed arrogant Dan, but in reality we are all far to busy improving our own individual and collective performances, to concern ourselves with the shortcomings and failings of other organisations.”

Qatar – United Arab Emirates

On the final leg of my trip we travelled to the worlds richest country that has the world’s third largest natural gas and oil reserves. Qatar will also host the 2022 FIFA World Cup. However the country has recently been in the media spotlight for all the wrong reasons. Highlighted in a recent Guardian news report that identified Qatar as having appalling human rights issues and horrific migrant worker death statistics.

With that said, visiting the country was the highlight of my trip as humbling experiences unfolded that will stay with me forever.

The purpose of our visit was to accompany Andy Sharp, the latest addition to Simian Skill’s expert team to the region to undertake training for one of the largest liquefied natural gas (LNG) producers in the world, producing in excess of 40 million tonnes of (LNG) per year.

You might say this was a Billion dollar company with state of the art training facilities…. ‘how wrong we were’.

The morning of the first day of training our driver arrived at our hotel and transported us to what we thought would be a state of the art training facility. On arriving in a residential area of Qatar those thoughts diminished as a Manager of this billion dollar company met the three of us at his front gate explaining his living room would be the venue.

“If kids in Africa can walk 10 miles to school each day we can educate these guys here! ”

With witnessing this very surprising development Terry and Andy’s professionalism and expertise shone through, they just got on with their mission to give the best training possible. Terry commented: “If kids in Africa can walk 10 miles to school each day we can educate these guys here! ”

Twelve plastic garden chairs and a plasma flatscreen TV awaited the manly Nepalese delegates. Those twelve experienced delegates had waited three years and paid for themselves for the opportunity to be educated to the highest possible standards in scaffolding by UK experts. The delegates welcomed and informed Terry and Andy of how “proud” they were, that they had actually come to their venue to teach them.

ScaffMag Interview: “Terry with the 2020 world expo event being held in Dubai and Qatar hosting the 2022 FIFA World Cup, do you think this will further help simian skill produce positive financial results ?”

Terry Sennett said:

“No doubt the awarding of both the 2020 World Expo and 2022 FIFA World Cup events in Dubai and Qatar respectively, are fantastic, well deserved and positive progress for the GCC region. These respective events will generate many opportunities for local businesses, which is a category I consider that Simian belongs to, after being based within the UAE for the last 4-years. Many internationally based company’s will no doubt flood into these regions, to take advantage of the huge foreign invested funds and the massive micro economic spike that these events always generate.”

“That said, my thoughts are firmly fixed on the overview of the region, long after these events have been and gone. This is why I consider it critical that Simian continues its successful strategy of achieving organic growth across the region. This has been achieved by entering Strategic Partnership Agreements with market leading organisations in the UAE, Oman, Qatar & Kuwait.”

“I am also currently in advanced talks to secure what will be our fifth such successful type partnering arrangement, which will cover the vast region of the Kingdom of Saudi Arabia. We are also actively searching for suitable premises, to enable the opening of our second fully resourced and accredited Training Centre in the UAE. We are dedicated and committed to remaining in the GCC region, to service our valued clients well after the Circus has left town, so to speak.”

ScaffMag Interview: “Terry after spending the last seven days with you in the Middle East I have caught on to your infectious passion and drive for making ‘THE’ change in the Middle East. What do you think is the best way to approach training in the GCC ?”

Terry Sennet said:

“Thanks for those kind words Dan, but what I do simply comes from a love and respect of our fantastic worldwide industry. To be driven & committed you must first be inspired. I was fortunate enough to hear NASC President Kevin Ward’s speech at last year’s Annual Ball, concerning getting 400x new apprentices into the industry & Lee Roswell’s GKR Academy concept, both resonated with me for different reasons. Our own Simon Hughes’s trek up, down and across the UK updating the industry in TG20: 13 at those Roadshow events. Ben Beaumont’s innovative and inspiring work, which is still a well kept secret for many and his recognition for services to the industry, by his appointment as a Director of The Temporary Works Forum, your own tireless work through Scaffmag Dan. All inspirational people and members of our brilliant industry, that regularly put something back into it, instead of continuously taking from it.

“I believe that we inspire others, to be inspired by what they do.”

“Regardless of nationality, be it Indian, Pakistani, Nepalese, they are all scaffolders! Members of our industry, fellow colleagues and their lives are not worth less than that of a UK scaffolder.”

“You were privileged to witness that unfolding of an unknown situation that caught us by surprise, in where 12x delegates had come together to pay for their own training. These delegates were fed up with their employers choice of training provider and had been waiting 3-years, to be provided with quality industry training of value. We thought we were off to some $billion organisation, with state of the art training facilities It was so much better than that! What an absolutely amazing and humbling experience, as the delegates welcomed and informed us how “proud” they were, that we had actually come to their venue to teach them! We responded by giving them the very best performance that we could deliver, we simply had to, as it’s our duty, responsibility, passion & commitment to do so!

These delegates had a common & shared cause that they believed was also shared by Simian. What is the best way to approach training delivery in the GCC region? Simply put, I believe that we inspire others, to be inspired by what they do, get it?”

Making ‘THE’ Difference

As my time in the region came to a close, I could not help but feel that Simian Skill are making great efforts to obtain a monumental change in the region. By supplying delegates with quality UK industry training the trainee will gain valuable scaffolder competency, which will, in-turn achieve fundamental positive changes and will undoubtedly save many lives. That said, if Simian continue to have the organic growth needed to expand in the region, the requirement for passionate experienced instructors will become apparent. In my opinion with only a small number of registered scaffolding instructors in the UK, further investment will be required for a specific teaching academy for highly experienced scaffolders to progress into the domain of educating others.

The exciting developments between Terry Sennett and Ben Beaumont that have been announced in this article provides us with an indication that Terry and Simian are already laying the foundations to pioneer and innovate for the future.

Finally, If you was to ask me, can Simian Skill make THE difference in the Middle East I would surprisingly say…no ! Simian Skill ARE making the difference.

Written by Daniel Norton.

(Founder & Editor) of ScaffMag.com

(I would like to thank Terry and Fiona Sennett for their expert guidance,hospitality and inspirational words during my time in the GCC. I would also like to thank Ian Fyall and Simon Hughes for giving me the opportunity to experience the Middle East for myself.)

UPDATE: Offshore North Sea worker who died is named by police

A worker who died on an offshore oil platform in the North Sea has been named by police.

Sean Anderson, 43, from the Tyne and Wear area has been named by police as the scaffolder who died . The Cape employee died after falling from BP’s Unity platform at around 4am on Thursday (4th Sep) The man was part of a team carrying out routine maintenance on BP’s Unity platform when the incident happened. Cape said it would work closely with BP, police and the Health and Safety Executive (HSE) on a thorough investigation. A Cape spokesman has said on Thursday: “It is with deep regret that Cape confirms the death of an employee following an incident this morning. “The deceased was part of a Cape team carrying out routine maintenance onboard BP’s Unity platform. Our thoughts go out to his family, to whom we will be offering every support. “The deceased’s co-workers are obviously shocked and saddened and we are working alongside BP to ensure they receive the support they need.” The Unity platform is situated 97 miles off the cost of Aberdeen.North Sea Worker Falls To His Death Offshore

A worker has died on an offshore oil platform in the North Sea.

A Cape employee has died after falling from BP’s Unity platform at around 4am this morning (4th Sep) The man was part of a team carrying out routine maintenance on BP’s Unity platform when the incident happened. Few details of the incident are known at this stage, but Cape said it would work closely with BP, police and the Health and Safety Executive (HSE) on a thorough investigation. It is also unknown at this stage if the man was a scaffolder or not. A Cape spokesman has said:“It is with deep regret that Cape confirms the death of an employee following an incident this morning. “The deceased was part of a Cape team carrying out routine maintenance onboard BP’s Unity platform. Our thoughts go out to his family, to whom we will be offering every support. “The deceased’s co-workers are obviously shocked and saddened and we are working alongside BP to ensure they receive the support they need.”The Unity platform is situated 97 miles off the cost of Aberdeen. More to follow..

Safety & Access Opens Training Facility In South Korea

Safety & Access Ltd announce the opening of a brand new CISRS Scaffolding Training facility in South Korea.

CISRS have given the facility the green light by awarding the training firm with it’s accreditation for the delivery of scaffolder skills training, scaffold inspection and scaffold supervisory qualifications.

Safety & Access have provided CISRS training in the region for almost two years and almost exclusively to their client Samsung Heavy Industries (SHI) that operate at the Geoje Island site in the South of the country. The new centre will provide key support training services to Samsung and their scaffolding operations and other clients in the region. Samsung recently presented Safety and Access with a further two year programme of training for CISRS scaffolding qualifications.

CISRS Scheme Manager Mr David Mosley said:

“We are delighted to be able to grant accreditation to Safety & Access as this centre demonstrates the growing popularity and recognition of the CISRS scheme across the globe. We are also thankful to Samsung Heavy Industries for supporting and promoting the overseas scheme.”

The opening of this new facility adds to an expanding list of Safety & Access centres as the firm recently announced expansion in the Middle East earlier this year.

Joint Managing Director of Safety & Access Rick Statham commented:

”We recognise and promote only independent CISRS accreditations for scaffolding in the UK and internationally and are extremely proud of this ongoing recognition of our professional and dedicated approach to providing quality training to our clients.”

“We would also like to thank our client Samsung Heavy Industries for investing in the provision of the scheme and we look forward to continuing this service for years to come in the region.”

For more information please visit www.safetyaccess.co.uk.

Scaffolder Sentenced After Unsecured Gin Wheel Falls 7m

A Scaffolder has received a suspended prison sentence after a unsecured gin wheel fell seven meters fracturing a man’s skull.

Christopher Harvey a West Midlands scaffolder received a four month prison sentence suspended for 12 months and ordered to pay compensation of £2,500, after a builder suffered a fractured skull when a gin wheel fell seven metres and struck his head. Birmingham Magistrates’ Court heard 27-year-old Mark Jones, from Darlaston, was installing lead flashing on a school roof using a gin wheel erected by Christopher Harvey, who was trading as Cannock Wood Scaffolding , when the incident happened on 8 August 2013. Mr Jones, who was working for a sub-contractor on the site, was operating a ‘gin wheel’, which is used to hoist and lower materials with ropes. The wheel had been attached to the scaffold by Christopher Harvey. As Mr Jones was loading materials from the ground ready for lifting to the roof, the wheel, weighing four kg, fell seven meters from the scaffold and struck him on the head fracturing his skull. He has since made a full recovery. A Health and Safety Executive (HSE) investigation found that Mr Harvey had failed to properly secure the gin wheel to the scaffold – no scaffold fittings were used to prevent the gin wheel from falling off the end of the scaffold tube, and the supporting structure was inadequately braced. Christopher Alan Harvey, 40, of Wolverhampton Road, Cannock, West Midlands, pleaded guilty to breaching Section 10(1) of The Work at Height Regulations 2005 and received a four month prison sentence suspended for 12 months and ordered to pay Mark Jones compensation of £2,500, plus £527.56 in costs. Speaking after the hearing, HSE Inspector Edward Fryer said:“This incident was entirely preventable and could easily have been avoided had Mr Harvey followed the published guidance to attach the wheel securely. Gin wheels are a common accessory for scaffolders and must be attached correctly. The installation of this gin wheel fell far short of the expected standard and made it almost inevitable that it would fall from the scaffold endangering anyone walking beneath. “Mr Jones suffered a fracture to his skull, but it is nothing more than luck that he was not more seriously injured, or even killed. “If you are installing scaffolding or associated lifting equipment, it must be left in a safe condition. The quality of work could make the difference between life or death.”

Powerclad Sheeting Prevails Over Hostile Offshore Conditions

Powerclad Flame Retardant Filter Sheeting from Industrial Textiles and Plastics (ITP) has been successful in withstanding the rigours of the exposed conditions in the North Sea to facilitate the refurbishment of an oil rig derrick. Maintenance and inspection work on offshore oil rigs is undoubtedly complicated and dangerous, a problem magnified on those located in the North Sea. Recent repair work to the derrick on the Bideford Dolphin, situated off the coast of Norway was a particular challenge due to the extreme wind speeds. The two-fold effect of these conditions is an accelerated corrosion of the rig structure, and a difficulty in repair and refurbishment works. Built in 1975, the Bideford Dolphin forms part of the Dolphin drilling fleet that consist of 2 deep water units, 5 semi-submersible drilling rigs, as well as a support vessel and accommodation unit. Dolphin Drilling is one of the longest established independent drilling contracting firms in the offshore arena tracing its roots back to the earliest offshore exploration activity in the North Sea in the mid 1960’s. Specialising in innovative access solutions for fabric maintenance and inspection, Skanits AS was selected to undertake the repair work to the derrick on the Bideford Dolphin. The containment system on the derrick was erected in 48 hours, and remained secure for the 19 days of the works, protecting the workforce and allowing drilling operations to continue. Alf Rune Falck, Director of Skanits AS said: “The Powerclad sheeting withstood the fierce conditions and provided excellent protection for the workforce and equipment. The use of the safe work zone system enabled us to work at several levels at one time, saving us a total of 10 days.” Managing Director at ITP, Marc van der Voort said:

Powerclad Flame Retardant Filter Sheeting from Industrial Textiles and Plastics (ITP) has been successful in withstanding the rigours of the exposed conditions in the North Sea to facilitate the refurbishment of an oil rig derrick. Maintenance and inspection work on offshore oil rigs is undoubtedly complicated and dangerous, a problem magnified on those located in the North Sea. Recent repair work to the derrick on the Bideford Dolphin, situated off the coast of Norway was a particular challenge due to the extreme wind speeds. The two-fold effect of these conditions is an accelerated corrosion of the rig structure, and a difficulty in repair and refurbishment works. Built in 1975, the Bideford Dolphin forms part of the Dolphin drilling fleet that consist of 2 deep water units, 5 semi-submersible drilling rigs, as well as a support vessel and accommodation unit. Dolphin Drilling is one of the longest established independent drilling contracting firms in the offshore arena tracing its roots back to the earliest offshore exploration activity in the North Sea in the mid 1960’s. Specialising in innovative access solutions for fabric maintenance and inspection, Skanits AS was selected to undertake the repair work to the derrick on the Bideford Dolphin. The containment system on the derrick was erected in 48 hours, and remained secure for the 19 days of the works, protecting the workforce and allowing drilling operations to continue. Alf Rune Falck, Director of Skanits AS said: “The Powerclad sheeting withstood the fierce conditions and provided excellent protection for the workforce and equipment. The use of the safe work zone system enabled us to work at several levels at one time, saving us a total of 10 days.” Managing Director at ITP, Marc van der Voort said:

“Powerclad Filter Sheeting provides exceptional weather protection in exposed locations and harsh climates such as the North Sea. It is a closed woven mesh for improved ventilation, as air permeability is desirable in many installations to contain debris and dust, disperse paint solvents and dry out interior works. Our expertise is in Flame Retardant materials, which should always be used for works on occupied buildings or on safety critical installations such as shipyards and refineries.”Working within a demanding framework of time, budget and safety limitations, the project was successfully delivered against all criteria with no disruption to the daily operations of the rig.