Worker injured after scaffolding board gives way

Business Leads: Kier on hunt for Midlands subcontractors

Time Lapse Video: Manchester Central Library Scaffolding

httpv://youtu.be/p5MF4JmKmN0

On our travels around the web we found this little beauty of a quick time lapse video from 2010 of the erection of what looks like a large birdcage scaffold inside the Central Library in Manchester UK. The video was uploaded in October by LAR Ltd.Let us know what you think in the comments below.

Cape plc shares fall by 30% after profit warning

Cape plc which provides scaffolding and industrial services for energy and oil companies across the globe saw it’s shares plunge after they announced today their third profit warning in 12 months.

The firm also announced today its chief financial officer Richard Bingham, had resigned with immediate effect and is expected to receive a contractual one-years pay-off.

The reason for the profit warnings comes after a downturn in work and lack of new projects in it’s onshore oil operation in Australia.

Cape are continuing an ongoing review of the onshore Australian business which would likely be complete before year-end.

According to the London Evening Standard Cape shares, which stood at 465p ahead of the November 2011 profit warning, crashed by a third today, falling 87p to a six-year low of 175p.

Cape plc which provides scaffolding and industrial services for energy and oil companies across the globe saw it’s shares plunge after they announced today their third profit warning in 12 months.

The firm also announced today its chief financial officer Richard Bingham, had resigned with immediate effect and is expected to receive a contractual one-years pay-off.

The reason for the profit warnings comes after a downturn in work and lack of new projects in it’s onshore oil operation in Australia.

Cape are continuing an ongoing review of the onshore Australian business which would likely be complete before year-end.

According to the London Evening Standard Cape shares, which stood at 465p ahead of the November 2011 profit warning, crashed by a third today, falling 87p to a six-year low of 175p.

By Daniel Norton

Let us know your thoughts on this story in the comments below

Southsea Hotel Scaffolding collapse [Video]

Scaffolding collapses due to high winds by PressAssociation

On the morning of April 25 2012 the scaffolding that was erected for painting on The Royal Beach Hotel collapsed in high winds. Five lifts of scaffolding came crashing down onto parked cars below. Luckily nobody was injured in the collapse.

Innovations: Advanced Guard

Easy-Fit guardrail panels slide up the stanchion posts, whilst locators fix the panel in place. At all times, scaffolding operatives are working from behind a safe barrier.

The Easy-Fit panels are left in-situ for the duration of the project, resulting in a finished scaffold, with fully guard-railed lifts and a completely gap free working platform. Scaffold inspectors can easily see that the scaffold has been installed in accordance with SG4.10 and will be confident that the scaffold can be dismantled safely.

The Easy-Fit panels incorporate a built in toeboard and brickguard which prevents tradesmen interfering with the units. When using conventional equipment, brickguards are regularly removed, rendering the scaffold platform unsafe and unfit for use.

The Easy-Fit system is the most flexible, total-security, scaffolding system available. Not only does it provide you with a single system solution to all your scaffolding needs, but saves you labour time and does not require qualified scaffolders to erect the safety zones on each lift.

Easy-Fit Posts

There are two simple to install support fittings. One Easy-Fit post is for use exlusively with tube & fitting scaffolding (A), the other, for either tube & fitting or system scaffold (B).

Easy-Fit Panels

There are three sizes of easy-Fit panel, designed to overlap and slide-to-fit, providing a fully braced safety-zone, from which further lifts can be erected in full safety. The 3 sizes and the unique ability to overlap panels, provides ultimate flexibility. However, should you require it, bespoke panels can also be provided.

Easy-Fit guardrail panels slide up the stanchion posts, whilst locators fix the panel in place. At all times, scaffolding operatives are working from behind a safe barrier.

The Easy-Fit panels are left in-situ for the duration of the project, resulting in a finished scaffold, with fully guard-railed lifts and a completely gap free working platform. Scaffold inspectors can easily see that the scaffold has been installed in accordance with SG4.10 and will be confident that the scaffold can be dismantled safely.

The Easy-Fit panels incorporate a built in toeboard and brickguard which prevents tradesmen interfering with the units. When using conventional equipment, brickguards are regularly removed, rendering the scaffold platform unsafe and unfit for use.

The Easy-Fit system is the most flexible, total-security, scaffolding system available. Not only does it provide you with a single system solution to all your scaffolding needs, but saves you labour time and does not require qualified scaffolders to erect the safety zones on each lift.

Easy-Fit Posts

There are two simple to install support fittings. One Easy-Fit post is for use exlusively with tube & fitting scaffolding (A), the other, for either tube & fitting or system scaffold (B).

Easy-Fit Panels

There are three sizes of easy-Fit panel, designed to overlap and slide-to-fit, providing a fully braced safety-zone, from which further lifts can be erected in full safety. The 3 sizes and the unique ability to overlap panels, provides ultimate flexibility. However, should you require it, bespoke panels can also be provided.

Health & Safety

The Easy-Fit system has also been rigorously tested and complies with all current legislation and best practise recommendations within the scaffolding and construction industry, including:

Health & Safety

The Easy-Fit system has also been rigorously tested and complies with all current legislation and best practise recommendations within the scaffolding and construction industry, including:

- The Health and Safety at Work etc Act 1974

- The Work at Height Regulations 2005

- The Manual Handling Operations Regulations 1992

- NASC; SG4;10

- Edge barrier strength tests: EN13374:2004e Class A Edge Protection

Trainee scaffolder suffered life-changing injuries after scaffolding fall

“This is a very stark example of the tragedy that can result from a task carried out at height without proper thought and planning. It has resulted in life-changing injuries for the worker and has had a devastating impact on his family. In addition, Mr Jessup was a personal friend, and he also has to live with the consequences of his role in the incident. “What happened that day was totally preventable if simple working methods had been followed and the untrained workers had been more closely and better supervised to ensure they carried out the work safely. “The scaffolding industry has produced guidance on the safe working methods to follow and this case sadly reflects the harsh reality of not doing so.”

Let us know your thoughts on this story in the comments below.

New system scaffolding lands in the UK

Let us know your thoughts on this new system in the comments below

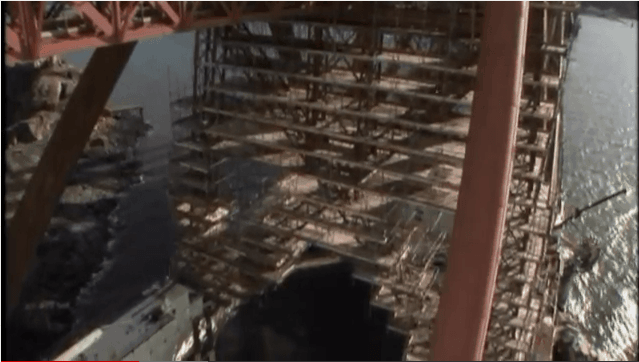

Insight into scaffolding on the Forth Rail Bridge

On 21st January 1890, two trains first crossed the Forth Rail Bridge, travelling across two and a half thousand metres of track suspended nearly fifty metres above the Firth of Forth. This feat of engineering remains an iconic structure and today requires equal feats of ingenuity to maintain. The exposed location, the extraordinary structure, 190 train movements per day and the busy shipping lane below, make this famous bridge one of the ultimate access challenges.

httpv://youtu.be/0k-U-rPYHIA

Scaffolding the bridge starts by reversing the conventional ‘ground-up’ approach. The evident complexity of the bridge, built with more curves than angles, means that every scaffolding member has to be individually designed, fabricated and suspended in position high above the Forth. Access platforms then have to be encapsulated in plastic sheeting, to prevent old lead paint being shot-blasted into the environment, and to protect the new, glass flake epoxy paint from the weather while it dries. The bridge is well over a hundred years old, but it takes 21st century technology and expertise to keep it in safe use, making Harsco Infrastructure’s experience on live industrial maintenance invaluable. To find out more about Harsco Infrastructure, visit: www.harsco-i.comLet us know your thoughts on this video in the comments below.

UK scaffolding and access giant unveils new look

![Southsea Hotel Scaffolding collapse [Video] Southsea Hotel Scaffolding collapse [Video]](https://scaffmag.com/wp-content/uploads/2012/11/scaffoldcollapsefeatured.png)