The engineering design consultancy firm, Independent Design House, (IDH)

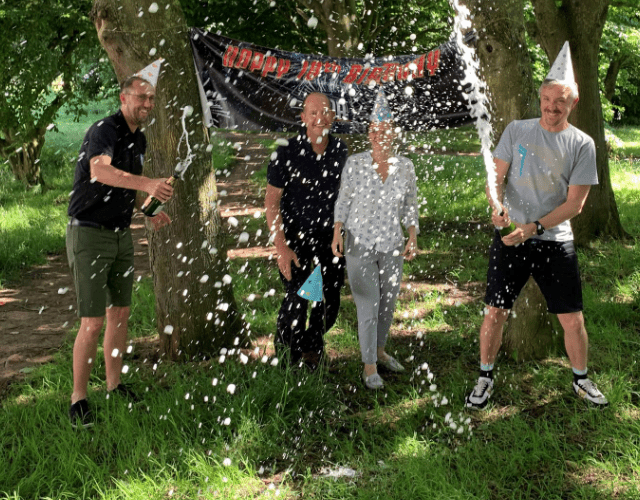

To mark the occasion, the company, which has bases in the UK, Poland and Bahrain, celebrated by raising a virtual toast with all employees, as each team member raised a glass to celebrate the company’s success.

IDH was started by CEO, Tim Burt, and Wojciech Wisniowski, in 2011 in Rochester, Kent. The demand for services offered by the company outgrew expectations and larger office premises were quickly required.

In 2013, IDH unveiled its new head office premises in Maidstone, Kent. The firm has since expanded further and now has offices in Poland, Bristol, Chorley, and Bahrain in the Middle East, employing over 40 members of staff.

IDH which works with industry-leading clients such as ISG and Laing O’Rourke Construction Ltd, offers both temporary and permanent works design; with full 2D draughting and 3D modelling services along with all BIM requirements.

Predominantly offering temporary works design, to include design and support for all bridge installation schemes, both steel and concrete, and other steel industry works ranging from structural frame design to connection design and Finite Element Analysis (FEA) and further temporary works design, plus full draughting services.

Tim Burt, CEO, attributes IDH’s exceptional growth to the “trusted and reliable” services provided to its clients. Tim Burt comments: “It’s brilliant to see the company expanding so organically and to see our approach continuing to reap rewards. I am extremely proud of the success IDH has achieved throughout its 10-year history and to be looking ahead to the next 10 years is very exciting. The team is exceptional, and we are very proud of the level of service we offer.”

“The next 10 years will involve opening more offices across the globe.”

Wojciech Wisniowski, Chief Engineer, adds: “To have been a part of IDH from the beginning of its journey has been a wonderful achievement. The next 10 years will involve opening more offices across the globe. It has been great to celebrate with the whole team in the UK and Poland virtually – let’s hope we are able to meet in person to continue celebrations in person very soon.”

A large Christmas gathering is planned for an in-person celebration. Previous annual celebrations have seen the entire team fly out to Poland for skiing and activity events and to Athens for a cultural exchange.

The company is eyeing rapid expansion in the UK, Poland and other European markets as well as further expansion in the Middle East market with an anticipated 100+ engineering roles.

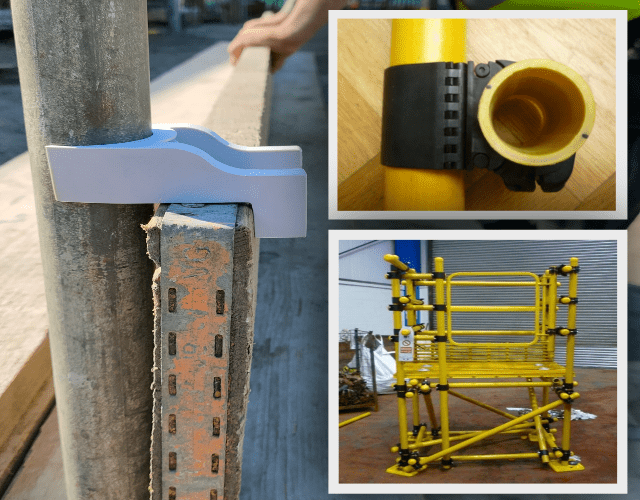

If you thought one superb creation would suffice however, how about a versatile toe board clip designed to allow toe-boards to be secured against adjacent standards without the need for tightening bolts? Once again industry experience has been put to good use. As a result, the new com-clip has emerged made from a material that will never corrode.

Now, toe boards can be attached to the adjacent standards with a reasonable manual force. Once attached to the tube they should remain in position requiring a small force to manually slide them into place over the board. when positioned over an edge toe-board the locking arms should protrude far enough to allow a second end toe-board to be secured between the arms. Correctly positioned they certainly won’t be a safety hazard in any way, and in carrying a low weight the construction task is made even easier.

There is currently no specified regulatory requirement for the strength of toe-board clamps. “For toe boards, the horizontal point load is 0.150kN.” This relates to the strength of the toe board itself to an outwardly directed force from operations on the platform. These outwardly directed forces on the boards would be resisted by the toe board bearing against the standards against which they are attached meaning com-clip® toe board Clips are more than adequate. NASC TG 20 has a similar requirement to BS EN 12811-1.

Looking even closer it’s also necessary for the clip to be able to resist an inwardly directed wind force of between 0.06 and 0.08kN (6 and 8kgf). Tests have demonstrated the com-clip toe board Clips have a pull-off capacity of 0.075kN (7.5kgf).

This article was first published in the

If you thought one superb creation would suffice however, how about a versatile toe board clip designed to allow toe-boards to be secured against adjacent standards without the need for tightening bolts? Once again industry experience has been put to good use. As a result, the new com-clip has emerged made from a material that will never corrode.

Now, toe boards can be attached to the adjacent standards with a reasonable manual force. Once attached to the tube they should remain in position requiring a small force to manually slide them into place over the board. when positioned over an edge toe-board the locking arms should protrude far enough to allow a second end toe-board to be secured between the arms. Correctly positioned they certainly won’t be a safety hazard in any way, and in carrying a low weight the construction task is made even easier.

There is currently no specified regulatory requirement for the strength of toe-board clamps. “For toe boards, the horizontal point load is 0.150kN.” This relates to the strength of the toe board itself to an outwardly directed force from operations on the platform. These outwardly directed forces on the boards would be resisted by the toe board bearing against the standards against which they are attached meaning com-clip® toe board Clips are more than adequate. NASC TG 20 has a similar requirement to BS EN 12811-1.

Looking even closer it’s also necessary for the clip to be able to resist an inwardly directed wind force of between 0.06 and 0.08kN (6 and 8kgf). Tests have demonstrated the com-clip toe board Clips have a pull-off capacity of 0.075kN (7.5kgf).

This article was first published in the

Speaking on the new products, Kevin Brannigan, Marketing Manager at Makita UK said: “With over 275 cordless solutions within our LXT platform, we are delighted to further expand the possibilities for professionals with these new additions.

Designed with purpose-built motors, innovative battery technology and enhanced communications, all our cordless tools work together to deliver reliable power, speed and run times that provide the trade with a cordless solution for every type of application.”

Speaking on the new products, Kevin Brannigan, Marketing Manager at Makita UK said: “With over 275 cordless solutions within our LXT platform, we are delighted to further expand the possibilities for professionals with these new additions.

Designed with purpose-built motors, innovative battery technology and enhanced communications, all our cordless tools work together to deliver reliable power, speed and run times that provide the trade with a cordless solution for every type of application.”