Isle Of Wight Council Launches New Scaffolding Initiative

Scaffold firm refuses to take down job over pay dispute

A scaffold firm owner is refusing to remove scaffolding from a newly-redeveloped city centre apartment block in a dispute over pay.

Norwich Evening News reports that Russell McVey claims he is owed more than £21,000 by the developers of Grosvenor House on Prince of Wales Road in Norwich. The 31-year-old’s company was contracted by Intro Developments in 2017 to erect scaffolding around the former office block. But following completion of the work to turn it into 80 flats, he claims he is still owed money by the Manchester-based firm. And he is now refusing to remove scaffolding from the property in protest. He said to local media: “If we leave the scaffolding up our hope is that they will realise that they need to pay us. It should have been down weeks ago and everyone should have been paid by now. But they are saying they won’t pay me another penny.” In response, Intro Developments, which is part of MCR Property Group, said it had paid what was owed to Mr McVey and his company Aboveall Scaffolding Services. Chris Taylor, fund manager for MCR, warned if the scaffolding was not removed, his company will take it down.Mr McVey said Intro Developments had so far paid £269,261 for the work. But he claims he is yet to receive an additional £21,584 for the cost of scaffold and hoist hire between April and May this year. The original fee was £157,368, but Mr McVey said it became more expensive due to changes with the project. VPH Roofing and Scaffolding, based in Watton, owns the existing scaffolding on the side of the property. The company was brought in by Mr McVey to help with the work. A spokesman for VPH said the company had “no intention” of taking the scaffolding down. Mr Taylor, from MCR Property Group, said: “As per Intro Developments’ business relationship with Aboveall Scaffolding Service, we have four purchase orders on record. “The four purchase orders were paid in full, including all costs, and there is no amount owing.” He said if Intro Developments has to remove the scaffolding, Mr McVey’s company would be charged for the work. “If they cannot pay then we will sell the scaffolding, take out costs and return the balance to Aboveall,” Mr Taylor said.Partnership brings first CISRS approved training centre to Saudi Arabia

A new CISRS approved scaffolding training facility in Saudi Arabia has been launched by TAFE Arabia (Technical and Further Education) in partnership with Simian Skill.

At the new training facility, located in Dammam, operatives will be able to undertake CISRS Overseas Scaffolders Training Scheme (OSTS) Level 1 and 2, Basic Inspection, Scaffolding Supervisor and OSTS CPD courses. Abdulghani Alrumaih, CEO of TAFE Arabia, said: “TAFE has been providing high quality training in this region for over a decade. When we considered offering scaffold training we were only interested in delivering CISRS OSTS approved programmes. “We are very proud to be the first CISRS OSTS in Saudi Arabia and sure our partnership with Simian Skill will be a great success, improving the skills of the scaffolding sector and helping to establish a robust and recognised qualification across industry.” Dave Mosley, CISRS Scheme Manager, and Ian Fyall, Operations Director at Simian Skill, travelled to Saudi Arabia for the accreditation audit at the new training centre. Whilst in the Region CISRS, TAFE and Simian took part in Scaffold Safety Awareness Workshop arranged by multinational oil and gas company Saudi Aramco, attended by more than 100 delegates from across the province. Dave Mosley said: “I was very pleased to take part in the Scaffold Safety Awareness Workshop and would like to thank Saudi Aramco for the invitation. While CISRS UK has historically been recognised in Saudi Arabia, the development of OSTS will allow the scheme to be delivered to the sector locally, reaching a much larger proportion of the industry.” Ian Fyall added: “Simian has had a lot of interest for training in the Kingdom of Saudi Arabia and have previously met with a number of providers. TAFE stood out from the crowd as they shared our ambition. “We’ve worked together during the past 12 months to get this centre up and running to KSA standards. From our meetings with Saudi Aramco we are feeling positive for full training courses.”Altitude Scaffolding reaches new heights with two new Volvo trucks

Hull-based, Altitude Scaffolding has added two Volvo FE 26-tonne rigid trucks to its own account transport fleet.

The trucks are the first brand-new heavy vehicles bought by the company, in addition to being the largest types operated to date. From its base in Freightliner Road, Hull, Altitude Scaffolding predominately works across central England, but the company does, as with previous contracts, operate across the UK and Ireland. Supplied by Pete Atkinson, Area Sales Manager at Crossroads Truck and Bus Limited in Hull, the two Volvo FE rigids are powered by Volvo D8K Euro-6 engines rated at 320hp. Behind the power plants, Altitude Scaffolding opted for Volvo’s award-winning I-Shift automated transmission system with 12 gears. The low height chassis are fitted with drop-side scaffold bodywork, which was specified with a 9,000mm length and a width of 2550mm. Malcolm Black, Operations Manager at Altitude Scaffolding has a long career association with Volvo trucks that stretches back to the F12 and FL10 models. “We have a mixed marque fleet, but the Volvo trucks we’ve previously bought second-hand have always been reliable,” he reports, explaining, “The company required vehicles with a larger payload capacity to deliver bulk supplies of scaffolding to out of town jobs.” “The 26-tonne Volvo FEs tick a lot of boxes for us. We can deliver enough supplies to keep a team of scaffolders busy for days and the optional third cab seat means we can also move crew members if required,” continues Malcolm adding, “the scaffolding equipment we carry is heavy, but fully-loaded, the FEs will only be operating at around two thirds of their maximum gross operating weight. This means less wear and tear on the trucks and of course, keeps us right with legal compliance.” “Our drivers are ‘over the moon’ with the FEs and are a massive step up from what we had,” Malcolm concludes.ScaffMag Issue 3 Out Now

Summer is officially here…The long-awaited summer issue of ScaffMag has now been published online.

Spread over 66 pages our Summer issue features an array of fantastic articles concentrating on the rise of system scaffolding that is currently driving change within the UK scaffolding & access industry.

We look at the current high profile project at London’s Big Ben and we find out what makes the world largest system scaffolding manufacture Layher tick when we visited their factory in Germany. Our new writer Andrew Kitley ‘Cracks the system’ as he shares his opinions on the various types of systems on the market and we find out why the relatively new system Plettac Metrix is a real tower of strength. Plus much more…

*NEW* Enjoy ScaffMag in Print

After an overwhelming amount of requests for a printed version of ScaffMag, we can now offer this option to our readers for just £5.88+p&p. Click the link below to order your copy now.View The Digital Copy

If a printed copy is not your bag and you would like to read our free digital copy on a desktop computer or on a mobile device while on the go please click hereSubmit News / Advertise In The Next Issue

Got some interesting industry news you would like to be featured in our next issue? Or do you have a product or service you want to showcase to thousands of industry eyeballs? We have a variety of advertising spaces available in our next issue. Drop us an Email »Rilmac provide access solutions for new military rehabilitation centre

Rilmac Scaffolding announces their involvement with the DNRC (Defence & National Rehabilitation Centre) project near Loughborough.

Northampton based Rilmac Scaffolding provided access solutions on site for the duration of the build, a contract that saw an investment of £600,000 in new equipment, over 15 new staff and took around two years. Another company in the Rilmac Group, Rilmac Asbestos Services were also on site removing asbestos from key locations in the main building. The official handover of the DNRC was held on 21st June with Prince William (a patron of the charity raising money for the centre), the Duke of Westminster (whose father began the project), and the Prime Minister in attendance. Prince William read a special poem on the theme of remembrance written by A&E nurse Debbie Lawson as part of the ceremony. Seven members of the Rilmac team were proud to attend the handover ceremony and share in the celebration of the opening of this key facility for British service men and women. The DNRC is four times the size of its predecessor Headley Court and will continue the work of dealing with amputees and complex brain injuries. In addition to gymnasiums and hydrotherapy pools, it offers cutting edge technology such as 3D printing of prosthetic limbs. “It’s one of the most challenging contracts that we have been involved with,” said Des Booth UK MD of Rilmac Scaffolding, “and seeing it looking like it did at the handover made me stand back and just say wow to myself.” Mark Green, who was project director on the DNRC project said of Rilmac Scaffolding, “I think Wow is the right word, a tremendous effort by your team throughout the project. I look forward to the opportunity to work together again.” “It has been a privilege to work on the DNRC,” said Rilmac Scaffolding Northampton director Sam McSpadden, “and I’d like to add a special thank you to all of our employees who have been involved on site.”HSE Issue Access Safety Alert

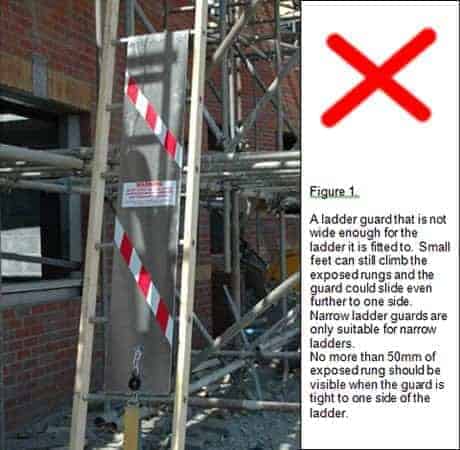

The Health and Safety Executive (HSE) has issued a new safety alert expanding on existing scaffold guidance. The move is aimed at enhancing current procedures to offer even greater protection to both construction workers and the public.

Key issues centre around site access points of a construction site including scaffolding and ladders. Preventing unauthorised access onto scaffolding or other work platforms is crucial in this sense. Children, for example, can view building areas as a potential playground, not having a grasp of the dangers they could face. With this in mind, gaps between gates and the ground, and between fixed and moveable fencing should be minimised so small children cannot climb through or under. Clients and contractors must ensure unauthorised access onto scaffolding is prevented, not just outside working hours, but also at times when workers are present but out of sight. These are principles long-established and set out in HSG151. All such routes may need to be secured by a combination of perimeter fencing, local fencing and ladder removal out of working hours. Or by securing ladders using a suitable ladder guard to make them un-climbable. The HSE emphasize where reasonably practicable, unauthorised access onto a construction site should be prevented by site perimeter fencing. At ground level, the full length of the scaffold may need to be fenced. In addition, there should be no projecting first lift transoms or ledgers to aid climbing. They also state where ladders need to be used, it is good practice to install internal ladders or a ladder tower so each ladder serves a single lift. As an alternative measure – where it is not reasonably practicable to remove bottom lift ladders out of hours, a ladder guard may be a suitable alternative. Site risk assessment should also carefully consider a range of appropriate controls to prevent or deter access. Examples in situations where the risk of unauthorised access is high are the use of:

Site risk assessment should also carefully consider a range of appropriate controls to prevent or deter access. Examples in situations where the risk of unauthorised access is high are the use of:

- Closed Circuit TV (CCTV);

- CCTV with active monitoring to detect the presence of persons;

- CCTV with active monitoring and loudspeakers allowing remote security monitoring and verbal intervention, and;

- Security personnel either based on site or by visiting patrol.

AIS helps train workers for Ireland’s thriving film industry

Industrial trainer, AIS is helping to train much-needed riggers for the growing film industry on the west coast of Ireland.

AIS Training, which is headquartered in North Shields, has worked with the Limerick and Clare Education and Training Board and Troy Studios to develop and deliver a new 10-day professional film rigging course in Limerick. The course provides an introduction to tube and fitting scaffold and has been specially tailored to the equipment and environments used in the film industry. Ireland’s film industry is booming with filming on the €53m budget production of the television adaptation of George RR Martin’s Nightflyers recently completed at Troy Studios. The much-anticipated Syfy series, being produced by NBC Universal and Universal Cable Productions, along with Wild Atlantic Pictures, is expected to screen on Netflix in the Autumn. Eimear Brophy, Further Education and Training Manager with Limerick and Clare Education and Training Board, said: “We were delighted to work with AIS Training to provide this much-needed training for the Irish film sector. With no previous large-scale film production studio in the region prior to the establishment of Troy Studios, it has been particularly difficult to source riggers for film work with the right level of training, “In fact, there is no certification for training tube and fitting in Ireland. So, following this course Limerick and Clare Education and Training Board and Troy Studios hope to develop a standard course with AIS Training that could be rolled out for the Irish film sector on a nationwide basis.” Dave Brannon, sales manager at AIS Training, said: “It has been a pleasure to develop this specialist course in conjunction with the Limerick and Clare Education and Training Board and Troy Studios. I understand Limerick has the potential to create up to 1,000 jobs in the screen production sector in the next three to five years so it’s great to be able to help the region up-skill its workforce in preparation.”Coventry Scaffolding collaborates with artist on major work in Hyde Park

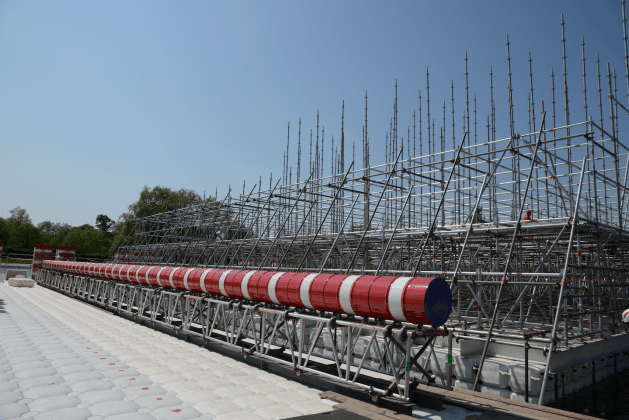

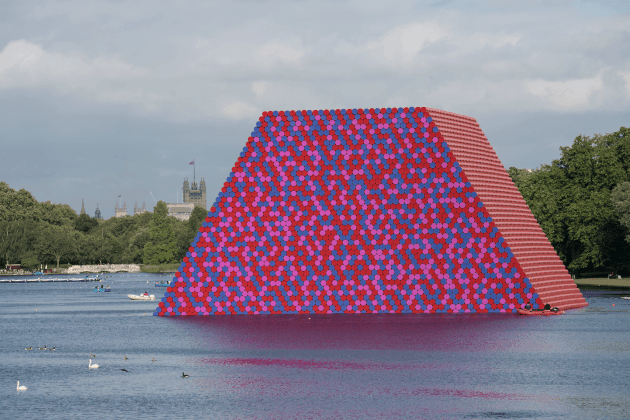

Coventry Scaffolding, leading independent scaffold contractor and Royal Warrant Holder to Her Majesty The Queen, has revealed its partnership with world-renowned artist, Christo, in his first major work in Britain – the majestic ‘Mastaba’. Floating on the Serpentine in London’s Hyde Park until 23 September 2018, the enormous structure, formed of 7,506 horizontally stacked barrels, required the expertise of Coventry Scaffolding to deliver an infallible structural solution.

“This was a very special and exciting opportunity for Coventry Scaffolding,” says Coventry Scaffolding’s Managing Director and Project Manager, Paul White. “We have worked on large art installations before at the Tate Modern but when I said yes to ‘a project in Hyde Park’, I had no idea it would be floating on the Serpentine.”

First contacted by Christo’s team in February 2017, Coventry Scaffolding was required to spend a month in Bulgaria (the artist’s native country) to work on a third-sized version of the ‘Mastaba’ on the Black Sea to trial the soundness of the design before beginning on its larger counterpart in London. The weight of the scaffolding originally caused the floating platform to sag in the centre but White and his team resolved this issue by placing a steel grid on top of the floating piers and this resulted in a firm and durable structure on which they could erect the scaffolding.

As part of a 100-strong project team from Austria, Belgium, Switzerland as well as England and Bulgaria, Coventry Scaffolding began to build the ‘Mastaba’ on the Serpentine on 23 April 2018. It took two months to complete and scaling up to the full 40m x 30m x 20m of the structure required additional rigidity by bracing every line of scaffolding along the length and breadth of the steel frame. “It was most impressive how a team from all over Europe worked together to overcome the project’s many challenges,” comments Paul.

He continues, “There was a lot of maths involved. Because the dimensions of the barrels as well as the 4x3x2 proportions of the structure, were fixed, tolerances were down to the very last millimetre; it was doubly difficult because of course, the barrels had to go in after the scaffolding was erected. Plus, Christo wanted the barrels to look like they were floating on the water, so the scaffolding couldn’t be visible above the water line.“

Jerome Szeemann, Project Master for the ‘Mastaba’, says, “We approached Coventry Scaffolding because of their excellent reputation and were especially impressed with Paul’s enthusiasm for the project.” He continues, “Despite the enormity of the installation and its challenges, Coventry Scaffolding’s skill and determination have ensured the ‘Mastaba’ is a great triumph.”

Hailing from Ancient Egypt, a Mastaba was a tomb-like funerary monument. Christo’s 650 tonne structure in Hyde Park is open to interpretation by visitors and will remain free to view for the public. The ‘Mastaba’ flaunts stunning red, blue and mauve hues, complementing the park’s greenery and embellishing the West London skyline.