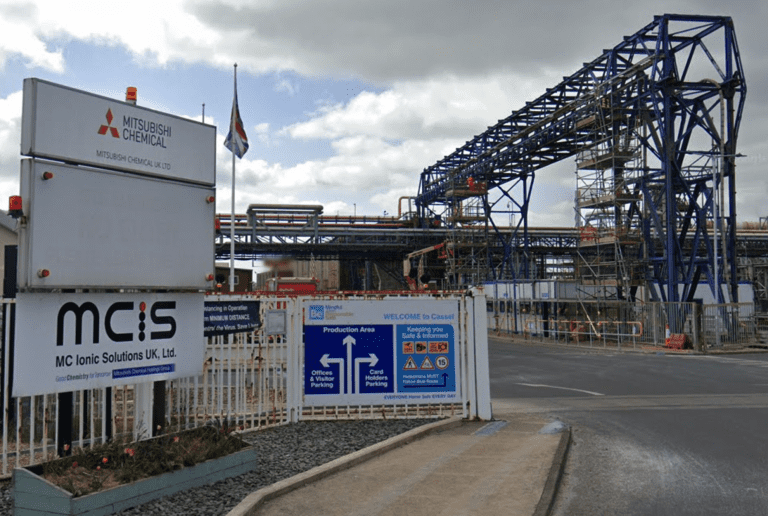

Chemical plant scaffolders strike postponed after ‘improved pay offer’

Alimak Group launches new Scaffolding Transportation System

Fuel card supplier to offset 100% carbon emissions for 1 billion litres of UK fuel

Forest Carbon

Forest Carbon, whose other partners include Microsoft, Siemens, Stagecoach and Ofcom, played a pivotal role in establishing national quality assurance standards that guarantee the ecological impact and carbon sequestration rates of any project. Their new woodland schemes are certified by the Woodland Carbon Code, which is supported by the UK government and internationally recognised by ICROA whilst their peatland programmes are certified by the Peatland Code which is supported by the IUCN. These certification codes guarantee that each tonne of carbon stored is permanent and incremental. Through planting over 13 million trees since 2006, Forest Carbon is already removing nearly 3 million tonnes of CO2 from the atmosphere, as well as providing other benefits to society including flood mitigation and enhanced biodiversity.

Industry firms partner to install sunken protest pontoon at COP26

Paul Price joins Lyndon SGB as Mechanical Access Director

“Our mechanical access teams always strive to treat each customer like they are number one – no matter if they only have small single MASTCLIMBERS™ or 10 large twin MASTCLIMBERS™ and multiple hoists on their project.

And this level of service quality goes back to the drawing board and in-house design teams, not just the on-site delivery and completion from our many skilled operatives.

“Having been part of Taylor’s Hoists growth in UK construction for 15+ years and the BrandSafway era, my expectations are very high, but I already know that the Lyndon SGB MASTCLIMBERS™ team is able to meet and deliver these high standards from what I have witnessed over the last month. We are all very excited about the future and the exciting projects we are currently and will be working on, in the whole of the UK.

“My vision is that we continue to perfect the great service we already offer, continue to invest in the newest, greenest fleets and ancillaries – assisting our clients with their mechanical access needs, however complex. I look forward to growing and aligning the mechanical access business with the great, large-scale team we already have to support our goal – to be the best access provider in the country.”

Lyndon SGB says, In the first month since Paul took on the new role, there have already been some significant changes – netting great rewards for Lyndon SGB, MASTCLIMBERS™ and Taylor’s Hoists customers countrywide.

“Our mechanical access teams always strive to treat each customer like they are number one – no matter if they only have small single MASTCLIMBERS™ or 10 large twin MASTCLIMBERS™ and multiple hoists on their project.

And this level of service quality goes back to the drawing board and in-house design teams, not just the on-site delivery and completion from our many skilled operatives.

“Having been part of Taylor’s Hoists growth in UK construction for 15+ years and the BrandSafway era, my expectations are very high, but I already know that the Lyndon SGB MASTCLIMBERS™ team is able to meet and deliver these high standards from what I have witnessed over the last month. We are all very excited about the future and the exciting projects we are currently and will be working on, in the whole of the UK.

“My vision is that we continue to perfect the great service we already offer, continue to invest in the newest, greenest fleets and ancillaries – assisting our clients with their mechanical access needs, however complex. I look forward to growing and aligning the mechanical access business with the great, large-scale team we already have to support our goal – to be the best access provider in the country.”

Lyndon SGB says, In the first month since Paul took on the new role, there have already been some significant changes – netting great rewards for Lyndon SGB, MASTCLIMBERS™ and Taylor’s Hoists customers countrywide. UK Scaffolding industry to be represented at London Build Expo

Small Business Commissioner calls on big firms to help SME’s reach net zero

Locals enjoy yardmans Remembrance Day display

How to produce a method statement and how does it help you manage risk?

What you need to consider with a method statement

The production of a method statement can seem like a daunting task. But knowledge about how the activity will be done and what the risks are will help to ensure that the document is relevant and importantly, that staff will follow it.- Firstly, when looking at the activity being carried out, refer to the risk assessment.

- Summarise the hazards present and make sure that the control measures are detailed and correct.

- Look further into the activity and consider if you will need any additional training for those doing the work, any permits or licenses, or personal protection offering higher levels of protection etc.

- The level of detail will increase the more complex the works are and the higher the risk is.

How to set out a method statement

There are lots of templates available for producing method statements but in general, they need to contain the following;- Clear title, show the address or location of the work, company details including management/staff names and emergency contact details.

- A description of the work or activity with start/completion dates, details of access restrictions, emergency procedures etc.

- Sequence of work. This should be kept simple to avoid confusion but contain enough detail for everyone involved to understand what will be done and how.

- Be reviewed when necessary

- The sequence of work can be in the form of a bulleted list and should outline what will be done from arrival on site, all the way through to leaving the site on completion of the work.

- Include references to any inductions required, the site set up, restricting access to the work area where needed, site clearing and removal of all waste and equipment at the end of the works.

Cut out the faff

We’re here to help you cut out the faff and our Alcumus Consultants can review your RAMS to help you ensure that they comply with current statutory and regulatory requirements. Call 01484 439930 or visit www.alcumus.com/faff-free to find out more.British Steel scaffolders in fifth week of strike action

Scaffolders at British Steel in Scunthorpe have entered their fifth week of all-out strike action in a long-running pay dispute with bosses.

As previously reported over 60 scaffolders employed by Actavo walked out of the steelworks in October and took to the picket line over a long-running row over their pay. Now into their fifth week of strike action backed by Unite the union, the scaffolders remain solid and determined in their fight for what they say should be the correct rate for the job. The workers want to be paid in line with the National Agreement for the Engineering Construction Industry (NAECI). The rates for the scaffolders are currently 10 to 15 per cent below these rates, according to Unite. Over the past five weeks, the scaffolders have picketed the three main gates at British Steel every day from 5.30 am till 2.30 pm. The group also held an early morning march that lead them around the site and into Scunthorpe town centre. Scaffmag understands that a strike committee has now been set up to involve more strikers in the running of the dispute, and are considering ways to up the ante on Actavo and British Steel bosses. According to the Socialist Newspaper, a family and friends Saturday town centre march has been suggested, and also a ‘solidarity with the Scaffs day’ to appeal to the 900 Unite members on the British Steel site to join the strikers on the picket line. The scaffolders have gained support from other construction workers joining them on the picket lines from nearby Keadby and Drax power stations.Solidarity to the guys showing up to the picket from Drax Keadby2???? @Actavo_HQ @BritishSteelUK @UniteSharon @ScaffoldingNews @UniteNEYH @unitetheunion @ScunthorpeLive @looknorthBBC #scaffolding #PayTheRate #Solidarity #Strike Retweet & share pic.twitter.com/7jOUwDtQ9N

— United Scaffs (@UnitedScaffs) November 1, 2021

Alistair Tice, Yorkshire Socialist Party said in a post: “To win, the dispute it needs active support inside British Steel, to stop other scaffolding firms doing Actavo work, and for British Steel Unite stewards to lead from the front by standing on the picket lines and talking to their members not to cross.”