Thanks to Brexit SafeTime launch new update to iOS app

The digital scaffolding inspection company SafeTime has launched an update to its Inspect7 app that now supports all Inspect7 hardware, including their electronic devices.

Due to Apple finally opening up the full potential of their devices this means SafeTime’s users no longer have to use Android handsets specifically to do scaffold inspections. And, it’s all thanks to Brexit, the London based company has said. See: Apple agrees to open iPhone NFC for UK’s Brexit app by end of 2019 Mitch Jackson at SafeTime said all you need to do is update the Inspect7 app to version 1.4 in the app store. The app update is available now and can be downloaded from the Apple App Store with an iOS device. However, the Inspect7 app is only compatible with iPhone models 7 and above and requires iOS 13 to carry out inspections on their electronic device. The update is available here. For more information visit: www.safe-time.co.ukTrade body Training Officer sent to prison

The scaffolding trade association NASC has recently gone behind bars in a bid to bring more recruits into the scaffolding industry.

With the ever-widening skills gap that the industry continues to face NASC Training Officer, Henry Annafi, attended insight/careers events at HMPs Peterborough and Thorn Cross. The trade body has said he was able to engage directly with prisoners and inform them of the broad range of careers available to them in the scaffolding industry upon their release. Henry and David Mosley, NASC Training Director, also visited HMP Featherstone in January to talk to Department of Work and Pensions and Ministry of Justice officials about the creation of a bespoke scaffolding training programme for inmates who are due for imminent release. Mr Annafi said: “As the trade body for access and scaffolding in the UK, the NASC recognises that it’s our responsibility to help the industry address the skills gap by raising awareness of the careers available to people of all backgrounds, abilities, ages and experiences.

“This recruitment drive has seen us engage with the Armed Forces, schools and colleges and more recently with the prison service and ex-offenders. At each of the prisons we visited in the past few weeks we found people looking to turn their lives around and also officials who were keen to discuss the possibility of working with us to provide better scaffolding training opportunities to inmates to help them find employment more easily upon their release.

“This is very much a work in progress but we’re confident we can make improvements in this area soon.”

Mr Annafi said: “As the trade body for access and scaffolding in the UK, the NASC recognises that it’s our responsibility to help the industry address the skills gap by raising awareness of the careers available to people of all backgrounds, abilities, ages and experiences.

“This recruitment drive has seen us engage with the Armed Forces, schools and colleges and more recently with the prison service and ex-offenders. At each of the prisons we visited in the past few weeks we found people looking to turn their lives around and also officials who were keen to discuss the possibility of working with us to provide better scaffolding training opportunities to inmates to help them find employment more easily upon their release.

“This is very much a work in progress but we’re confident we can make improvements in this area soon.” Top 50 UK contractors £5.5 billion contract awards

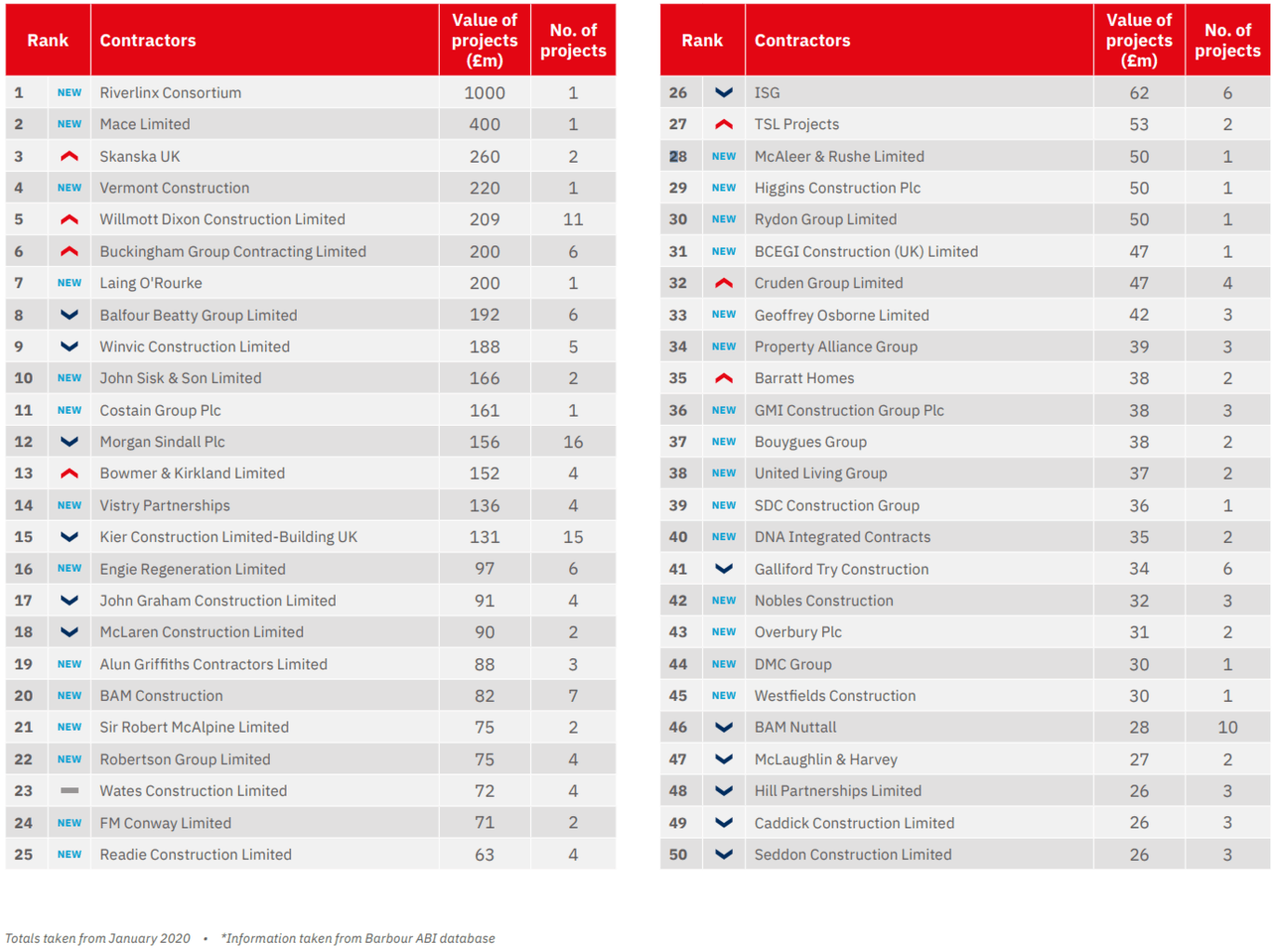

Industry analysts have revealed the UK’s top 50 contractors were awarded £5.5 billion of contract awards in January.

Construction intelligence firm Barbour ABI has reported the Riverlinx Consortium took the top spot during January with a single award valued at £1 billion to deliver the Silvertown Tunnel development in London. While Mace and Skanska were in second and third place with a total contract award value of £400 million and £260 million respectively. This month, the top three contractors have been awarded a combined four projects at a total value of £1.66 billion. The latest edition of the Top 50 League Tables published by industry analysts Barbour ABI, highlights the number and value of construction contracts awarded during January. This month shows that the combined value of contracts awarded to the Top 50 was £5.5 billion with a total of 182 projects. The overall value of all projects awarded to the top 50 contractors is up by 178% on December 2019 when the total value of projects was just £1.98 billion. The total quantity of projects also increased by 75% from December to January, suggesting that there have been both a number of high value contract awards as well as an increase in quantity of contract awards.

Tom Hall, Chief Economist at Barbour ABI & AMA Research said, “Activity has increased in January considerably compared to the latter months of 2019. However, these figures have been boosted by several major projects”.

Download the full report here: https://ubm.io/2WBolhM

The overall value of all projects awarded to the top 50 contractors is up by 178% on December 2019 when the total value of projects was just £1.98 billion. The total quantity of projects also increased by 75% from December to January, suggesting that there have been both a number of high value contract awards as well as an increase in quantity of contract awards.

Tom Hall, Chief Economist at Barbour ABI & AMA Research said, “Activity has increased in January considerably compared to the latter months of 2019. However, these figures have been boosted by several major projects”.

Download the full report here: https://ubm.io/2WBolhM North East Scaffolder’s Contract Success

Interlink Scaffolding (ISL) has been working on a major contract worth £5 million involving the worlds biggest waste energy plant currently under construction.

The Atlantic Project Company were looking for a scaffolding contractor to complete the works on the boiler-furnace, and all the associated tasks surrounding the biomass project, at the MGT site on Teesside. North East based ISL had already been appointed in 2018 to work on both the internal and external of the 16 silos storing the biomass. ISL said they used a complex design utilising the Layher Allround system scaffold to offer a working platform to the inside of the silos. With the scaffolding material being purchased directly from Layher for the project. The firm worked alongside both PHB and Technicas Redundas from Spain, on this phase of the job.

Later, a meeting was arranged with main contractors to discuss the possibility of ISL pricing works for the rest of the scheme. In fact, ScaffMag understands, 10 companies were asked to tender for the package as the Tyne and Wear scaffolders found themselves up against some big names within the industry. With five then being withdrawn, ISL then found themselves in a due diligence meeting to select the final two.

ISL Managing Director Darren Maratty, who is also Vice Chairman of the NASC Northern and North Wales Region told us: “A few people were a little sceptical of a predominantly ‘street work company’ tackling this type of project. We showed some of our past engineering and offshore projects alongside our recent Project of the year success. We also had a slight advantage over our competitors given our knowledge of the local workforce, and also our strong presence in the north-east. In the end, this probably contributed to ISL eventually winning the contract back in October 2019.

Later, a meeting was arranged with main contractors to discuss the possibility of ISL pricing works for the rest of the scheme. In fact, ScaffMag understands, 10 companies were asked to tender for the package as the Tyne and Wear scaffolders found themselves up against some big names within the industry. With five then being withdrawn, ISL then found themselves in a due diligence meeting to select the final two.

ISL Managing Director Darren Maratty, who is also Vice Chairman of the NASC Northern and North Wales Region told us: “A few people were a little sceptical of a predominantly ‘street work company’ tackling this type of project. We showed some of our past engineering and offshore projects alongside our recent Project of the year success. We also had a slight advantage over our competitors given our knowledge of the local workforce, and also our strong presence in the north-east. In the end, this probably contributed to ISL eventually winning the contract back in October 2019.

New design and technical roles introduced at HAKI

System scaffolding provider, HAKI, has announced the appointment of Ross Turner as Chief Technical Officer (CTO) and promoted design engineer, Priscila Escobar, to UK Design Manager; both newly created positions within its business.

Ross Turner has joined the senior management team at HAKI Group following the company’s acquisition of Span Access in December last year, where he was Managing Director since 2012.

With more than twenty years’ experience in the access industry, Turner is well-placed as CTO to deliver on the company’s technical requirements, HAKI said in a statement.

He will be responsible for driving pioneering technical solutions and methodologies that encourage safer working practices in temporary works from the organisation’s new innovation centre in Scotland

Turner will be overseeing the entire engineering and technical team across all markets.

Priscila Escobar, who has been working in a design capacity at HAKI for three years, will now lead the design engineering function for the UK market.

Embracing the UK Design Manager role, Escobar will liaise directly with customers to develop effective tailored solutions for their specific projects. HAKI has said, she will also work closely with external consultants and in-house design teams, to ensure all designed works using HAKI provide the highest levels of safety and efficiency.

Escobar will also assist with the testing of new products, maintain all technical literature, develop and integrate design and BIM tools alongside the VDC team, and form part of management to work on other key UK initiatives.

The introduction of both roles reflects the increased demand for design engineering and technical services, particularly in complex temporary works projects, where Safety by Design is becoming a necessity.

Turner commented: “It goes without saying I am excited about my future at HAKI and the opportunity to place innovation at the centre of our business.

“It’s clear the merging of both Span and HAKI technical teams will benefit the development of our core products as well as a range of new market-leading solutions for complex temporary works.

“I truly believe that the future of temporary works is evolving and further development of our BIM and VDC tools is essential in delivering first-class solutions and technical support for our clients.

“We are also very pleased that Priscila has accepted the role as Design Manager. Her knowledge of our products, design capabilities, and overall enthusiasm for the temporary works sector has led to some outstanding work over the past three years. The promotion is well-deserved, and we look forward to seeing her thrive in the new position.”

Speaking on her promotion and concluding, Escobar said: “It is very exciting to be part of HAKI during this new chapter in the company’s expansion. The integration of Span Access within the business paves the way to a larger offering of access solutions and new development opportunities.

“I am very excited to be taking on this new role under Ross’ leadership and look forward to further support our clients with the very best solutions as we continue to grow.”

Altrad Services bags more work on Teesside

Altrad Services has won more work at the site of the former Redcar Steelworks.

In a project partnership between Altrad and the South Tees Site Company, the firms are set to commence the environmental remediation of equipment at the site of the former Redcar Steelworks. The work will involve the treatment and removal of contaminated waste to allow future redevelopment of the site and creating opportunities for future local industrial development. Over the next two years, the project partnership will generate new job opportunities for the local community, some of which has already commenced, says Altrad. Altrad Services Managing Director, Tony Jester said: “We are delighted to be working with the South Tees Site Company and local organisations such as Middlesbrough College to create job opportunities for the local Redcar and Cleveland area. “Developing the land at the site of the former steelworks is a crucial part of the region’s redevelopment and will allow new industries to invest in the area, creating jobs for the future.”KAEFER acquires Wood’s industrial services business

KAEFER has announced the acquisition of Wood’s industrial services business from John Wood Group PLC in the UK and Ireland.

The global industrial services firm has stated the business is becoming a wholly-owned subsidiary of KAEFER Group. It’s understood that the two companies will merge into one company that will operate as KAEFER all over the UK and Ireland. Reports suggest Wood’s industrial services business was sold for an initial payment of $104 million. A potential further $14 million will be paid pending on the business achieving agreed financial goals. KAEFER has said the merger will provide its clients with additional capacities, know-how and project management capabilities. Wood’s industrial services business employs approximately 2,000 highly skilled people at 16 locations all over the UK and Ireland. The company provides high-end services for industrial operations, such as the application of protective coatings, access solutions, thermal insulation, passive fire protection and specialist services. “Our clients will continue to receive the same high-quality service they have come to expect plus the extra value offered by both companies working together,” says Steen E. Hansen, Co-CEO at KAEFER.

Prison sentence after scaffolder dies from 30ft fall

A scaffolding company boss has been jailed after a scaffolder fell 30ft to his death while dismantling a temporary roof in Kensington.

Southwark crown court heard how the boss of G&L Scaffolding and Roofing, Kevin Leathers, 41 had ignored previous safety warnings which lead to the death of scaffolder Jon Currie, 36.An experienced scaffolder

The experienced scaffolder lost his footing while dismantling a temporary roof of corrugated sheets. Mr Currie was not wearing a safety harness and suffered “catastrophic brain damage” in the fall in July 2017. Mr Leathers pleaded guilty to failing to ensure the health, safety and welfare of his employees and was jailed on Monday for eight months, according to the Evening Standard. He had been warned previously by the Health and Safety Executive (HSE) in April 2017. His employees including Mr Currie had been spotted working dangerously in Kensington without safety harnesses. The court heard Mr Leathers had been sent a letter reminding him of strict health and safety requirements. Prosecutor Simon Denison QC said: “This was a clear warning that practices were unsafe. It is obvious that being up on a temporary roof and without safety equipment is highly dangerous.” Its was also found that no risk assessment had been carried out and Mr Currie was not qualified for the job he was doing on the day he died. Mr Denison added: “Mr Leathers failed to exercise his duty of care and as a result, Jon Currie died while working for him. Mr Leathers intentionally breached, or flagrantly ignored, the law.”

Kewazo scaffolding robot raises €2.5M funding strengthens management

Munich based Kewazo has raised a further €2.5 million in funding for its scaffolding robot and added ‘high-calibre’ industry experts to its management team.

The Kewazo scaffolding robot has now raised a total of €3.6 million in funding, the firm now aims to obtain certification of the product and to release the first batch of the series systems “Liftbot” to the market. The former managing director of Layher Germany Dr. Helmut Kreller and Uwe Braun former managing director of Losberger have both joined Kewazo’s management team. The duo brings many years of experience from the construction and scaffolding industries. In 2018 we reported that engineers at Kewazo had created a scaffolding robot which is set to make the erection of scaffolding more efficient by delivering scaffolding materials to scaffolders where and when they need them.The Kewazo Scaffolding Robot – how does it work?

The Kewazo scaffolding robot works by moving up, down and along a scaffold by means of a special track attached to horizontal and vertical tubes of the job. After a successful bauma trade show in April 2019, the company is currently piloting the system on construction sites. Dr. Helmut Kreller said: “I will be happy to support KEWAZO with my technical and industry-specific experience to advance digitization and automation in the industry. Scaffolding assembly services are in a state of change due to an increasing shortage of skilled workers and a permanent need for optimization. I am convinced that such innovative solutions as Liftbot, which significantly reduce costs of scaffolding assembly and at the same time increase safety, will change the industry in the long term.”

Uwe Braun added: “I am looking forward to investing all my energy, experience and enthusiasm in such a young and dynamic startup. I see an enormous automation potential for the traditionally labor-intensive scaffolding assembly with the Liftbot. It is an exciting and challenging task for me to accompany the highly motivated KEWAZO team into a promising future.”

Dr. Helmut Kreller said: “I will be happy to support KEWAZO with my technical and industry-specific experience to advance digitization and automation in the industry. Scaffolding assembly services are in a state of change due to an increasing shortage of skilled workers and a permanent need for optimization. I am convinced that such innovative solutions as Liftbot, which significantly reduce costs of scaffolding assembly and at the same time increase safety, will change the industry in the long term.”

Uwe Braun added: “I am looking forward to investing all my energy, experience and enthusiasm in such a young and dynamic startup. I see an enormous automation potential for the traditionally labor-intensive scaffolding assembly with the Liftbot. It is an exciting and challenging task for me to accompany the highly motivated KEWAZO team into a promising future.”

KEWAZO CEO Artem Kuchukov concluded: “We are very proud to have Dr. Helmut Kreller and Uwe Braun in our management team. With their decades of experience and operational knowledge in scaffolding and construction industries, we are all set for the upcoming challenges.

The new investment will help us to reach our certification milestones and to ship the first systems already in this year. We are grateful for the strong support of our investors and their believe in us and in the power of construction automation.”

KEWAZO CEO Artem Kuchukov concluded: “We are very proud to have Dr. Helmut Kreller and Uwe Braun in our management team. With their decades of experience and operational knowledge in scaffolding and construction industries, we are all set for the upcoming challenges.

The new investment will help us to reach our certification milestones and to ship the first systems already in this year. We are grateful for the strong support of our investors and their believe in us and in the power of construction automation.”