SG4:15 – Preventing falls in Scaffolding Operations announced

The NASC have announced the latest edition of the safety guidance SG4 – Preventing falls in Scaffolding Operations.

For almost 20 years and 200,000 copies later the popular guidance notes SG4 continues to be revised and developed for the better, which has now become the established minimum standard for fall prevention in the scaffolding industry today.

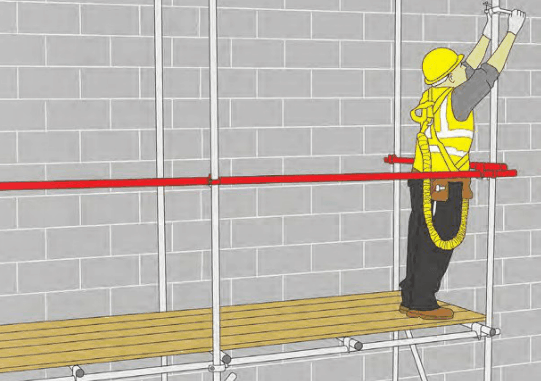

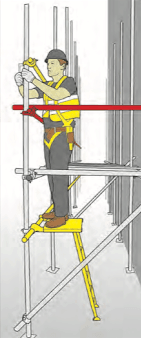

With a new title ‘SG4:15 – Preventing falls in Scaffolding Operations’ is described in the new NASC Yearbook 2016 as “evolution not revolution” it continues to focus on the current preventative and protective measures that are classed as good practice, like for instance, creating the ‘Scaffolders Safe Zone’.

Many of the principles of SG4 remain unchanged in this update, however SG4:15 provides more guidance on systems of work and available equipment to help comply, also a wider selection of methods for a contractor to consider for creating the ‘Scaffolders Safe Zone’

Overall SG4:15 reflects the focus of the guidance to protect scaffolders working at height during erection, alteration and dismantling procedures.

The latest edition of the guidance will be launched later this month at the NASC AGM in Leeds on 27 November.

to be revised and developed for the better, which has now become the established minimum standard for fall prevention in the scaffolding industry today.

With a new title ‘SG4:15 – Preventing falls in Scaffolding Operations’ is described in the new NASC Yearbook 2016 as “evolution not revolution” it continues to focus on the current preventative and protective measures that are classed as good practice, like for instance, creating the ‘Scaffolders Safe Zone’.

Many of the principles of SG4 remain unchanged in this update, however SG4:15 provides more guidance on systems of work and available equipment to help comply, also a wider selection of methods for a contractor to consider for creating the ‘Scaffolders Safe Zone’

Overall SG4:15 reflects the focus of the guidance to protect scaffolders working at height during erection, alteration and dismantling procedures.

The latest edition of the guidance will be launched later this month at the NASC AGM in Leeds on 27 November.

TRAD Group – Going for Growth

New TRAD Commercial Vehicle Fleet – Protecting People and the Environment and enhancing service levels.

TRAD is proud to announce the completed purchase of 15 new Scania HGV units complete with 1.5 Ton Fassi Cranes at a cost of £1.7 million. These modern high quality vehicles are fully Euro 6 compliant helping us to protect the environment by reducing emissions, particularly in London where TRAD Co mainly operates, this is part of our continuous drive to reduce our carbon footprint and improve our Environmental Management System accredited through BSI to ISO 14001.

Moreover, as part of our continuing focus on improving safety for our Employees and the General Public, all 15 vehicles have been fitted with top of the range cameras. These enhancements help protect Cyclists and Pedestrians by substantially reducing blind spots in the Driver’s field of sight. TRAD currently holds Bronze FORS Accreditation and this purchase of the new Scania HGV units solidifies our commitment to achieving the FORS Silver standard early next year.

Furthermore, these new Lorry Loader Cranes enable a much safer working environment with a major advancement in remote controlled Lifting Operations. All TRAD’s HGV drivers have received certificated Training, allowing them to control every aspect of the lifting process from any position around the truck, thus resulting in increased visibility of all operations improving safety and enabling us to give a better quality service to our customers.

New Trucks – New Livery

The new trucks have been liveried with distinctive new paintwork

The trucks have been transformed into a highly effective form of mobile messaging, promoting continual awareness of our Behavioral Management Programme ‘Play it Safe’ as well as promoting both the TRAD Group and ALTRAD Group Brands.

NASC shortlisted for Pride of Construction Award

The National Access and Scaffolding Confederation (NASC), has been shortlisted for a top award for its outstanding commitment to supporting apprentices.

NASC is in the running for a prestigious Pride of Construction Award at the annual industry prize-giving run by the Construction Industry Training Board (CITB). The awards celebrate all of the best people, companies and partners in the construction industry. This year’s ceremony, which takes place on 25 November at the Natural History Museum in London, arrives at an exciting time for the construction industry, with 10,000 jobs forecast to be created in Greater London alone over the next five years. The NASC has been nominated in the Outstanding Strategic Partner category in recognition of its best practice initiatives such as its commitment to apprenticeships, and its promotion of the scaffolding industry training scheme (CISRS). NASC Director of Training, Dave Mosley commented: “We are very pleased to be nominated and shortlisted for this Pride of Construction award. As the UK’s scaffolding and access trade body (NASC) we work closely with CITB to make the construction industry a safer place in which to work. “It’s gratifying to receive recognition from CITB for our role in achieving this; and indeed to be recognised for our work as a CITB strategic partner. We have a long and proud history of working with CITB, helping to raise the profile of industry training in the construction sector.”Workers jump for their lives as scaffold collapses

Three firms have been prosecuted by the HSE after workers had to literally jump for their lives when a huge scaffold collapsed into the River Brain in Essex.

Renovation work was underway at the Former Riverside Centre, Braintree when on the 1 July 2014 a forty meter run of independent five lifts high collapsed. Workers leapt through open windows to avoid falling with the huge scaffold. The HSE commenced a full investigation into the incident and charged three firms with various breaches of law. Principal contractor Parkland Developments Ltd, scaffolding contractor SC Cousins Scaffolding Ltd and CDM co-ordinator Haze and Safety Ltd all found themselves before Chelmsford Magistrates’ Court. The court heard HSE’s investigation found numerous failings on site;- The CDM co-ordinator had failed to provide suitable and sufficient advice to the client (Parkland Developments Ltd) or ensure that the arrangements were being implemented on site.

- The principal contractor (Parkland Developments Ltd) failed to implement the construction phase plan or ensure that they planned and managed or monitored the scaffolding works.

- The scaffolding contractor failed to plan the work or design the scaffold. They also failed to send trained and competent workers to site. In the weeks prior to the collapse, a scaffolding labourer was acting as the supervisor and overseeing trainee scaffolders in erecting, altering and inspecting the scaffold.

- Not one of the duty holders had identified there was no design for the scaffold.

Cape awarded two year Australian contract

Industrial services contractor Cape plc, has secured a two year contract with Woodside in Western Australia.

The new contract has been awarded to a 50/50 joint venture between Cape and UGL for services on the Woodside operated Karratha Gas Plant Life Extension Program. Services to be provided include the detailed planning and execution of access, fire protection application, blasting and painting, cladding and insulation, mechanical, pipe-spool equipment replacement and electrical services. The contract is for a two year period with work expected to commence on site at the beginning of 2016. Located 1,260 kilometres north of Perth, Western Australia and covering approximately 200 hectares, the Karratha Gas Plant includes five LNG processing trains, two domestic gas trains, six condensate stabilisation units, three LPG fractionation units as well as storage and loading facilities for LNG, LPG and condensate. The plant has the capacity to produce 12,000 tonnes of domestic gas per day. Joe Oatley, Chief Executive of Cape, said: “We are delighted to announce the award of this new contract with Woodside which was won through our innovative approach and combined service offering with our contract partner, UGL. Woodside is an important client and we look forward to working with them closely to deliver safe and efficient service on this extensive project.”XERVON Palmers wins Rydon contract at prestigious Ealing Green Man Lane project

XERVON Palmers bags scaffolding contract at the £155M Green Man Lane regeneration project in Ealing, London.

The well-known scaffolding and industrial services contractor has been appointed by successful southern-UK-based construction, development, maintenance and management group Rydon. XERVON Palmers operatives will be providing access solutions on Phase two of works commencing this Autumn – crucially utilising specialist Layher Scaffold system – facilitating the construction of 187 new homes within apartment blocks which are due for completion in early 2017. For the scaffolding and access, Palmers will be utilising circa 400 tons of the Layher all round system scaffolding to provide access to Blocks A, B G & H of the Green Man Lane regeneration. And there will be a typically eclectic picture of scaffold provided, including façade, birdcage, stairways, loading bays and cantilevered access. The four phase Green Man Lane project for Clients London Borough of Ealing is being delivered in a 50:50 joint venture partnership with A2Dominion and Rydon – aiming to regenerate the Green Man Lane estate in the West London borough. The project value is £155M and is expected to take nine years. The existing 464 flat local authority housing estate is being demolished – paving the way for 770 new homes (300 for open market sale and 400 for affordable rent and shared ownership homes for A2Dominion). Ian McFarlane, Director for Business & Project Development at XERVON Palmers said: “We are thrilled to be working with Rydon on the superb Green Man regeneration project – regenerating an important part of the capital. The contract confirms Palmers strategy to make a difference by offering our customers an alternative to traditional tube and fittings within the UK Market, with our system scaffold solutions. And one of the key factors in securing this contract was our ability to provide Layher scaffolding to the developer, as we also did recently at Aberthaw Power Station.” And Donald Morrison, CEO of XERVON Palmers added: “Congratulations to our regional team for securing this contract, which is our first major success with Rydon. We are very much looking forward to doing a great scaffold and access job, which will hopefully pave the way for a long-term future of quality work with the construction group in London and the South.”Bilfinger strengthens relationship with Maersk Oil following contract award

Bilfinger Salamis UK awarded five year contract with Maersk Oil North Sea for an undisclosed sum.

Following a period of competitive tender, industrial services company Bilfinger Salamis UK has been awarded a contract for the provision of fabric maintenance and associated services by Maersk Oil North Sea (Maersk Oil). The contract, which begins in November, is for a period of 5 years and includes coatings, access, specialist cleaning and shutdown support services on all Maersk Oil’s UK upstream assets. Bilfinger Salamis UK has worked with Maersk Oil since 2009, completing a number of successful fabric maintenance and ‘walk to work’ campaigns. Bilfinger Salamis UK managing director Graham Hayward commented: “This award is fantastic news as it enables us to build on our close working relationship with Maersk Oil, and allows us to demonstrate our commitment to delivering safe operations, while developing the scope of services we provide.”CN Specialist Awards 2016 finalists announced

The Construction News Specialist Awards 2016 has announced it’s shortlisted finalists.

The eleventh Construction News Specialist Awards will take place on 24 February 2016 at the Hilton Park Lane, London. After stiff competition In the Access & Scaffolding Specialist of the Year category, judges have whittled down the entries to just eight companies.- AFI group

- Chris Sedgeman Scaffolding

- Everlast Scaffolding

- GKR Scaffolding

- SafeTime ®

- St Helens Plant

- TIGER Scaffolding

- UK Platforms

2015 TRAD Scaffolding workforce Seminar

The presentation ended with an overview of TRAD’s key achievements throughout the past year, our success in securing many large Contracts in 2016 thus ensuring continual work for our workforce and Staff, avoiding any seasonal downturn and the Board of Directors commitment to recognising and rewarding safety and quality in the workplace.

Recognising Achievement

An important part of the seminar was to recognise our people’s achievements, with a special award for exemplary efforts in Health & Safety going to various Scaffolders across the three Operational Divisions headed by Divisional Directors, Chris Smith, Peter McShane and Tony Mileham.

Chris, Peter, and Tony presented the prizes and awards, including those for “Divisional Scaffolder of the Year” and “Best Improved Scaffolder of the year”, for those who best exemplified and implemented our 5 Key Safe Behaviours (Excellent Segregation, Safe System of Work, PPE, Housekeeping and Quality).

Winners were as follows:

Chris Smith’s Division:

Dean Lomiglio – Divisional Scaffolder of the Year

Luke Faik – Best Improved Scaffolder of the Year

Peter McShane’s Division

Karl Clinton – Divisional Scaffolder of the Year

Corey Belgrove – Best Improved Scaffolder of the Year

Tony Mileham’s Division

David Yates – Divisional Scaffolder of the Year

Oliver Wheatley – Best Improved Scaffolder of the Year

The final award presented was for Safe Employee of the Year – the criteria of which was based on our Clients’ recognition of our Scaffolders’ exemplary behaviour and their excellent control of our five Key Safe Behaviours on site.

This year’s winner was John Gardner – for leading the Scaffolding team on the highly prestigious “One Tower Bridge” Project for Berkeley Homes and John was also commended for being an exemplary colleague and running this high profile Project to a very high standard.

The afternoon finished with a Q&A session and opportunity for informal discussions with the Directors over refreshments in the function area. The Annual Seminar was once again considered a great success, by both the Staff and our Scaffolding workforce and the Company looks forward to a another mutually successful financial year and a continuation of this event in September 2016.

DES MOORE – TRAD GROUP MANAGING DIRECTOR commented:

Following our recent organisational re-structure and Neil’s well-deserved appointment to the MD position of Trad Co. Neil, his Divisional Directors and Contracts Staff have continued to recognise that it is absolutely essential that we engage with our whole workforce on all matters, which in my view remains at the heart of TRAD Co’s resilience and continued growth over the past 45 years.

The presentation ended with an overview of TRAD’s key achievements throughout the past year, our success in securing many large Contracts in 2016 thus ensuring continual work for our workforce and Staff, avoiding any seasonal downturn and the Board of Directors commitment to recognising and rewarding safety and quality in the workplace.

Recognising Achievement

An important part of the seminar was to recognise our people’s achievements, with a special award for exemplary efforts in Health & Safety going to various Scaffolders across the three Operational Divisions headed by Divisional Directors, Chris Smith, Peter McShane and Tony Mileham.

Chris, Peter, and Tony presented the prizes and awards, including those for “Divisional Scaffolder of the Year” and “Best Improved Scaffolder of the year”, for those who best exemplified and implemented our 5 Key Safe Behaviours (Excellent Segregation, Safe System of Work, PPE, Housekeeping and Quality).

Winners were as follows:

Chris Smith’s Division:

Dean Lomiglio – Divisional Scaffolder of the Year

Luke Faik – Best Improved Scaffolder of the Year

Peter McShane’s Division

Karl Clinton – Divisional Scaffolder of the Year

Corey Belgrove – Best Improved Scaffolder of the Year

Tony Mileham’s Division

David Yates – Divisional Scaffolder of the Year

Oliver Wheatley – Best Improved Scaffolder of the Year

The final award presented was for Safe Employee of the Year – the criteria of which was based on our Clients’ recognition of our Scaffolders’ exemplary behaviour and their excellent control of our five Key Safe Behaviours on site.

This year’s winner was John Gardner – for leading the Scaffolding team on the highly prestigious “One Tower Bridge” Project for Berkeley Homes and John was also commended for being an exemplary colleague and running this high profile Project to a very high standard.

The afternoon finished with a Q&A session and opportunity for informal discussions with the Directors over refreshments in the function area. The Annual Seminar was once again considered a great success, by both the Staff and our Scaffolding workforce and the Company looks forward to a another mutually successful financial year and a continuation of this event in September 2016.

DES MOORE – TRAD GROUP MANAGING DIRECTOR commented:

Following our recent organisational re-structure and Neil’s well-deserved appointment to the MD position of Trad Co. Neil, his Divisional Directors and Contracts Staff have continued to recognise that it is absolutely essential that we engage with our whole workforce on all matters, which in my view remains at the heart of TRAD Co’s resilience and continued growth over the past 45 years.