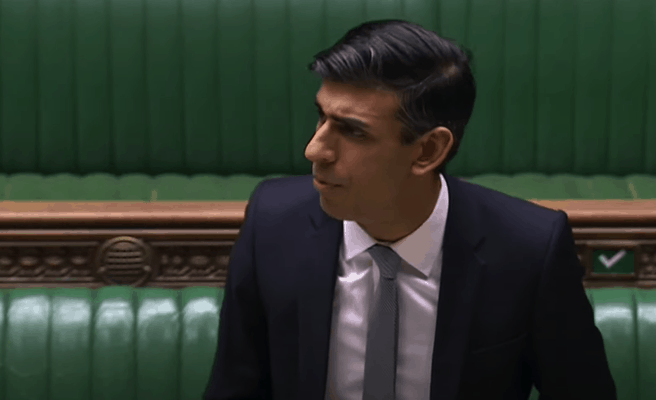

Rishi Sunak has unveiled a multibillion-pound package for business and workers.

The Chancellor today announced he will significantly increase the generosity and reach of his winter support schemes to ensure livelihoods and jobs across the UK continue to be protected in the difficult months to come, supporting jobs and helping to contain the virus.

In recognition of the challenging times ahead, the Chancellor said he would be increasing support through the existing Job Support and self-employed schemes, and expanding business grants to support companies in high-alert level areas.

This builds on agreements reached with Local Authorities moving to Alert Level very high, with extra support for businesses, jobs and the economic recovery.

Chancellor of the Exchequer Rishi Sunak said: “I’ve always said that we must be ready to adapt our financial support as the situation evolves, and that is what we are doing today. These changes mean that our support will reach many more people and protect many more jobs.

I know that the introduction of further restrictions has left many people worried for themselves, their families and communities. I hope the government’s stepped-up support can be part of the country pulling.”

Job Support Scheme (JSS)

When originally announced, the Job Support Scheme (JSS) – which will come into effect on 1 November – saw employers paying a third of their employees’ wages for hours not worked, and required employers to be working 33% of their normal hours.

Today’s announcement reduces the employer contribution to unworked hours to just 5%, and reduces the minimum hours requirements to 20%, so those working just one day a week will be eligible. That means that if someone was being paid £587 for their unworked hours, the government would be contributing £543 and their employer only £44.

Employers will continue to receive the £1,000 Job Retention Bonus.

Self-employed grant

Today’s announcement increases the amount of profits covered by the two forthcoming self-employed grants from 20 per cent to 40 per cent, meaning the maximum grant will increase from £1,875 to £3,750.

This is a potential further £3.1 billion of support to the self-employed through November to January alone, with a further grant to follow covering February to April.

Business Grants

The Chancellor has also announced approved additional funding to support cash grants of up to £2,100 per month primarily for businesses in the hospitality, accommodation and leisure sector who may be adversely impacted by the restrictions in high-alert level areas. These grants will be available retrospectively for areas who have already been subject to restrictions, and come on top of higher levels of additional business support for Local Authorities moving into Tier 3 which, if scaled up across the country, would be worth more than £1 billion.

These grants could benefit around 150,000 businesses in England, including hotels, restaurants, B&Bs and many more who aren’t legally required to close but have been adversely affected by local restrictions nonetheless.