Peri Group Acquires Stake In 3D Printing Company

The Peri Group has bought a ‘significant’ stake in the Danish 3D Concrete printing specialist COBOD International.

Peri, a global maker of formwork and scaffolding systems believes printing will play an important role in the construction industry. The German company will now make COBOD’s 3D concrete printers available to their customers worldwide. COBOD International is a newly established sister company of Denmark’s 3D Printhuset, which carried out a government-funded, three-year research project into advanced 3D construction printing. The technological breakthrough was achieved last year in Copenhagen when the so-called ‘BOD’ (Building On Demand) was printed with a 3D concrete printer from COBOD. The ‘BOD’ building was Europe’s first printed building. “As the market and technology leader in the field of formwork and scaffolding, we at PERI are closely following the development of 3D concrete printing in the construction industry. COBOD is a leading company in this business. The currently available BOD2 3D printer from COBOD shows that the technology is now ready for the market. With the BOD building in Copenhagen there is a first successful reference project”, says Leonhard Braig, member of the Group Management of the PERI Group. “We are convinced that 3D printing will become considerably more important in the coming years in certain segments of our industry, especially in residential construction. Together with COBOD, we now want to help this technology to a breakthrough on a broad basis.” “We are pleased and proud of PERI’s investment in our company. The fact that PERI is committed to COBOD impressively underlines the potential of 3D concrete printing in the construction industry”, says Henrik Lund-Nielsen, CEO of COBOD. “The investment brings together two technologically leading companies in each of their fields. We look forward to the completely new opportunities that the partnership with PERI opens up to us and our customers around the world.”Scaffolding Finalists Revealed for NASC 2018 Awards

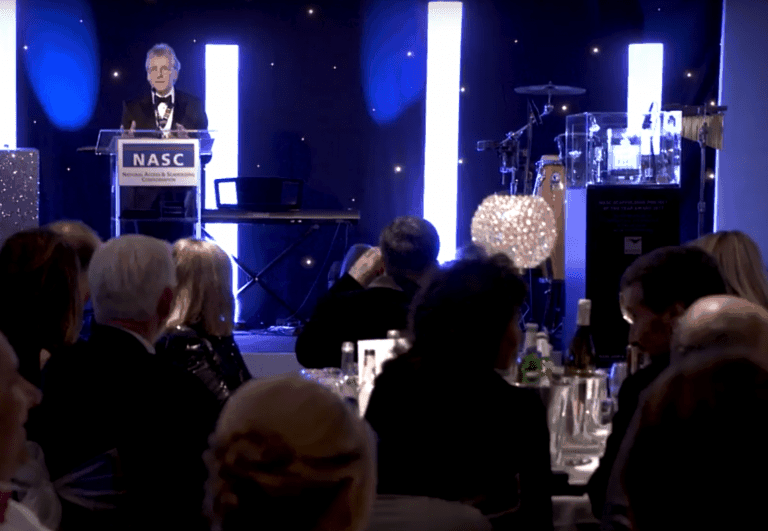

The National Access & Scaffolding Confederation (NASC) has announced the finalists for the forthcoming NASC 2018 Awards

The sellout event which showcases the very best scaffolding projects, processes, products and personnel, is to be held in Edinburgh at the Sheraton Grand Hotel & Spa on Friday 23 November. The NASC has said that over 40 entries were submitted for this year’s awards, these were scrutinised by a panel of judges comprising of main contractors and industry experts. Four finalists for each of the seven categories have now been selected.Apprentice of the Year

- George Duke – Connect Scaffolding Ltd

- Jordan Edwards – TRAD Scaffolding Company Ltd

- Robert Grant – ASC Ltd

- Callum Ward – KAEFER Ltd

Health and Safety Award – 1-66 Employees

- Allen & Foxworthy Ltd

- Complete Access Scaffolding Ltd

- Focus MDC Ltd

- Malvern Scaffolding Ltd

Health and Safety Award – 67+ Employees

- Connect Scaffolding Ltd

- GKR Ltd

- SCA Group Ltd

- TRAD Scaffolding Co Limited

Innovation Award

- GKR Ltd

- KAEFER Ltd

- PERI Ltd

- TRAD Safety Systems

Project of the Year – Turnover up to £5 million

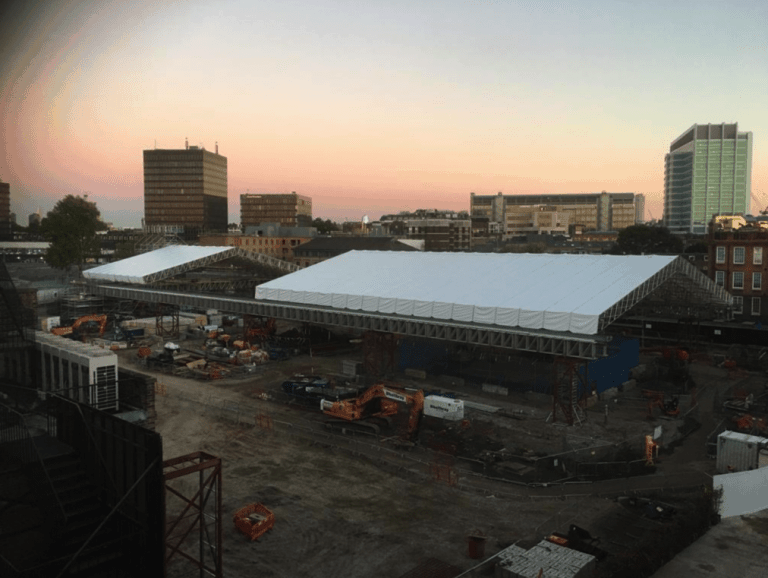

- CCS Scaffolding Ltd – Waterloo International Terminal Upgrade

- Chris Sedgeman Scaffolding Ltd – Longrock Depot, Penzance

- Coventry Scaffolding Ltd – The London Mastaba

- LTC Group 87 – UK Hydrographic Office Taunton

Project of the Year – Turnover in excess of £5 million

- GKR Ltd – Wimbledon Court One, London

- Millcroft Services plc – Athlone House, Highgate

- PHD Modular Access Services Ltd – Big Ben Conservation Project, London

- TRAD Scaffolding Ltd – Intu Watford Shopping Centre Roof

NASC President’s Award

- Chris Sedgeman Scaffolding Ltd

- High Peak Scaffolding Ltd

- RPF Ltd

- TRAD Group Ltd

TRAD Hire & Sales Release New Plettac Metrix User Guide

TRAD Hire & Sales are proud to announce the launch of the new User Guide and Component Capacity Manual for their revolutionary Plettac Metrix® System Scaffold.

An innovative ring based system, with horizontal dimensions that are completely metric, which allows both the tubular transoms and ledgers to be substituted by components of a smaller size, permitting the use of extra verticals within a bay length or width. This feature further advances efficiency and vastly increases the ease by which adaptions can be made.

Compliance to SG4 takes a further step forward with the use of the optional, system exclusive, Permanent Advanced Guardrail System. Providing collective fall protection for scaffold operatives (and all other trades), the advance guardrail is an integral part of the Plettac Metrix® scaffold structure from erection to dismantle.

There has been a real shift towards system scaffolding over the last few years, especially as the industry keeps pace with developments in Health & Safety and Training, whilst also maintaining its drive to be more cost-effective.

The market has embraced the simplicity of the Plettac Metrix® System Scaffold, which is enhanced by the aforementioned unique divisibility and optional Permanent Advanced Guardrail, allowing both time and cost savings to be easily achieved.

Plettac Metrix® System Scaffold is exclusive to TRAD Hire & Sales and is offered on both a Hire and Sale basis. They offer an unrivalled commitment to service, including extensive User Guides, Nationwide Training, Engineering and Design Support, Estimating Software, and a full on-site support service – their UK-wide network of depots have the resources and capabilities to meet every demand.

TRAD Hire & Sales are updating their full range of manuals and user guides. Look out for further releases including the new Altrix® Temporary Roof User Guide, over the next few months.

Training Scheme Pilot Scaling New Heights

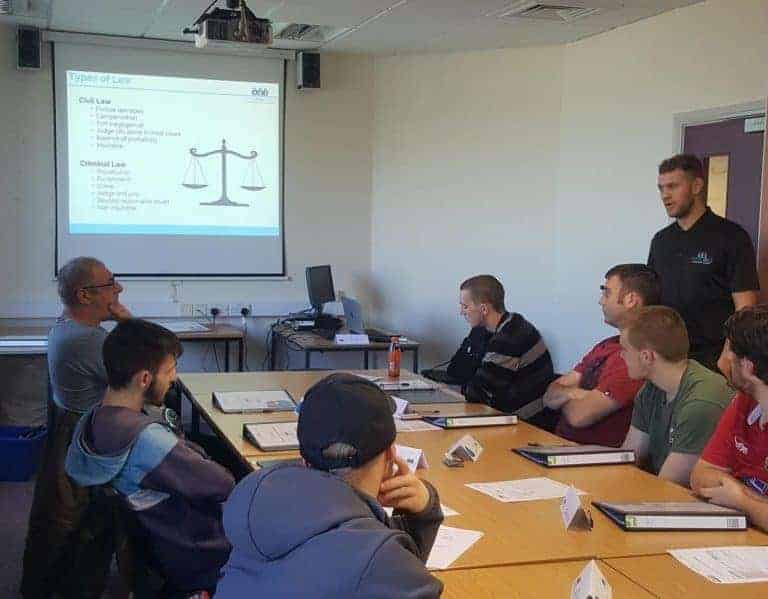

A pre-employment training scheme aimed at lifting barriers for those entering work is set to enhance opportunities within the scaffolding industry.

The pilot 10-day scheme will also include individuals looking to return to work, up-skill or change career direction. It’s all part of a collaboration between The Simian Risk Group, The Department Of Work And Pensions, Construction Wales Innovation Centre, College Cambria in Wrexham, 4c Access UK Ltd, Martin Scaffolding Services and The Arctic Scaffolding Company Ltd.A Qualified Success Story

Simian Business Development Manager, Simon O’Donnell told us: “The delegates work towards a number of qualifications including Level 1 Award in Work Preparation, Level 1 Award in Mental Health Awareness & Well-being, Simian Aluminium Towers and CISRS COTS. “The course then involves a 4-day work placement with a local scaffolding contractor. Delegates will be working either in the yard or on-site, carrying out general labouring duties over four consecutive days, and by this stage they will already have gone through their CISRS COTS training, So will be ‘site-ready’. “The delegates are all recruited by the local jobcentre and all currently unemployed. The first stage of the process involves one of Simians consultants visiting the jobcentre to offer their insights and experience of working in the scaffolding industry. From there, interested delegates are invited to attend the course. For the pilot course this week eight delegates were offered the chance to participate and seven have attended, all who appear to be engaged and genuinely interested in completing the training. “We regularly hear about the skills shortages facing our industry and the recruitment issues faced by employers so we thought we could step in and help. By partnering with the jobcentre, local colleges and scaffolding employers, we are bringing all of the stakeholders together. This helps delegates gain a recognised CISRS qualification, which will hopefully give them the opportunity for employment and progression with the scaffolding industry.”Course Highlights

Highlights will involve responsible work practice, Health and safety in a practical environment, team-work skills, rights and responsibilities in the workplace, mental health and well-being and of course a work placement at a local scaffolding company. There will be a final review and feedback together with advice on the next steps to be taken. The whole project is aimed at both addressing the skills shortage and recruitment issues facing the industry. It’s been welcomed by a number of colleges and the Department for Work and Pensions. Simon added: “The qualification will help to obtain the generic and transferable skills needed to perform with confidence in a range of workplaces in the sector. It will also provide a range of employability skills needed for a career in scaffolding.”Looking Ahead

It’s hoped this will be the first of many with all parties hoping at least one person on the pilot course will be offered employment.One dead after scaffolding collapse in Belgium

Seven stories high scaffold has collapsed killing one and seriously injuring another at a hotel building in Antwerp, Belgium.

The collapse is positioned directly outside the busy central station. Emergency response teams were in attendance at the scene to see if anyone was trapped.

One person has died and another has been seriously injured in the collapse according to reports.

It is still unclear why the scaffolding collapsed.

Altrad Cape awarded three-year scaffolding contract in KSA

Altrad has announced its Kingdom of Saudi Arabia (KSA) subsidiary, RB Hilton Saudi Arabia, has secured a three-year maintenance contract with Sadara Chemical Company for the provision of scaffolding services.

The contract value for the three year period (plus 2 years optional) is estimated to be US$ 5M starting from December 2018.

Established in October 2011, Sadara is a joint-venture developed by the Saudi Arabian Oil Company (Saudi Aramco) and The Dow Chemical Company (Dow). It is an unprecedented undertaking – the world’s largest chemical complex ever built in a single phase, with 26 integrated world-scale manufacturing plants and capacity of over 3 million metric tons per annum. Sadara supports Saudi Arabia’s industrial and social diversification by extending key value chains downstream.

Altrad Cape says this award is a major strategic win for RB Hilton, providing them with an opportunity to develop a long-term relationship with Sadara chemical company.

Managing Director of the KSA Business Paul Cockerill commented: “We are delighted to secure this long-term contract with Sadara and increase our maintenance coverage within the kingdom”.

West Anglian Training Association falls into Administration

A leading scaffolding training provider has ceased trading leaving many scaffolders deeply concerned they will be left out of pocket.

According to sources the Cambridgeshire based training firm West Anglian Training Association Ltd (WATA) unexpectedly fell into administration yesterday (17th Oct). WATA provided a broad range of training including scaffolding, health, safety and environmental, quality management, electrical and mechanical skills training. Many people that had already booked and paid for courses were informed with a phone call from WATA explaining the position of the business and that all courses had been canceled. Paul Oldfield who had paid WATA £1,200 was due to start his CISRS Part 1 Course on the 29th said: “I got a phone call yesterday from WATA, they told me they had gone into administration and had canceled all courses. “When I asked for a refund they said they were sending out letters so people could claim. I’m pretty sure I won’t see my money again,” Oldfield added. The Construction Industry Scaffolders Registration Scheme (CISRS) posted a message on their website after the scheme’s helpline was inundated with calls from disgruntled WATA customers asking for advice. CISRS Scheme Manager said: “It was very disappointing to hear that WATA had ceased trading, this was not something we were expecting. We have great sympathy for those who have paid up front for training and may well now lose their money. “CISRS has left messages with the administrators in order to let us know what actions those affected can take and also if we can retrieve any portfolio’s, training records or certificates so people may continue their training with another provider. “We are currently speaking to other CISRS providers to see if they can assist in any way.” ScaffMag understands that Mctear, Williams and Wood are acting as interim administrators Tel. 0800 331 7417 https://www.mw-w.com We have reached out to WATA for comment, and await their reply.Three injured after Cotswolds scaffolding collapse

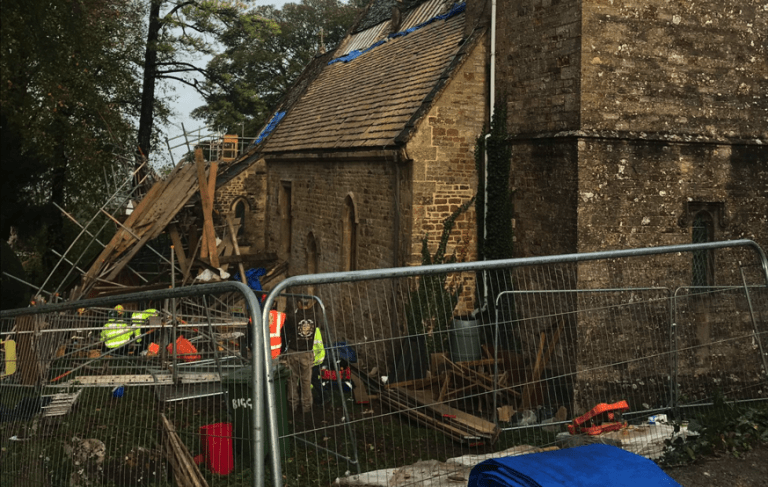

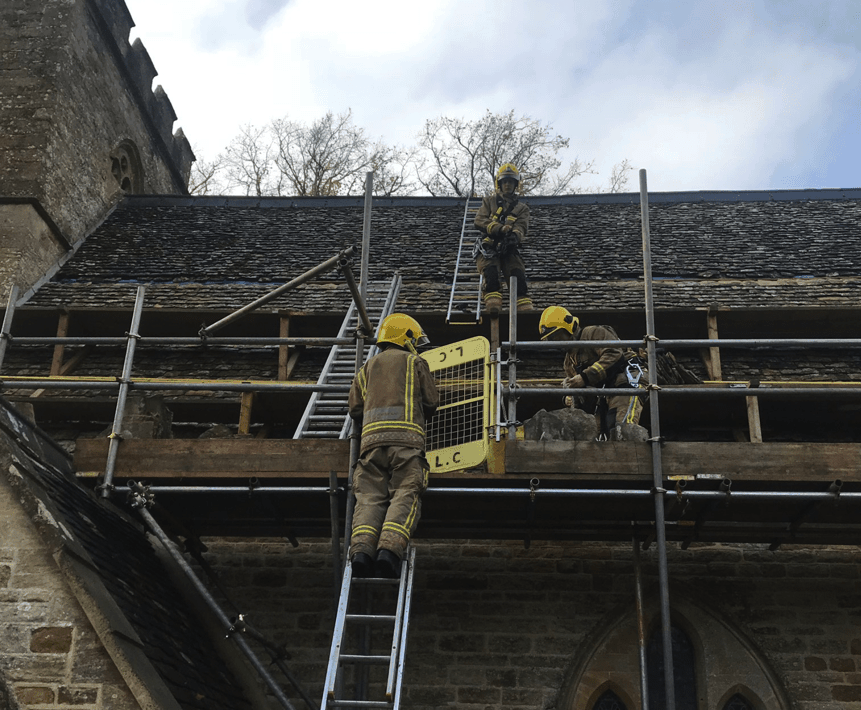

Three workers were taken to hospital after a scaffolding collapsed on a Church in the Cotswolds.

Local media has reported that on Tuesday afternoon (October 16) scaffolding that was erected for roofing works collapsed at an address in Church Westcote near Chipping Norton. Three men were injured in the collapse and taken to a nearby Hospital in Oxford. Two of the men are believed to have suffered non-serious injuries while the extent of the other man’s injuries is unknown. Ambulance and fire services attended the scene. Crews from Moreton and Stow fire services assisted in the rescue of the casualties. Fire officer Ian Tonner tweeted: “Excellent to oversee Moreton and Stow crews at this incident earlier. “Four people rescued and safe systems of work put in place to ensure no more danger. The Health & Safety Executive is aware of the incident.

Scaffolding Director Sentenced for VAT Fraud

A scaffolding company director has been sentenced for almost £100,000 tax fraud that she tried to blame on an innocent employee.

An HM Revenue and Customs (HMRC) investigation found that AIM Access Solutions Ltd director, Amanda Noble, lied on her VAT returns. She had submitted more than 40 false invoices to evade paying £98,000 from her company.

The VAT returns for the Liverpool-based business included many invoices for work falsely claimed as zero-rated, so no VAT was paid.

According to The Business Desk investigators from HMRC questioned Noble about the problem, but she insisted an employee dealt with the VAT returns and she never looked at them. It was revealed she had lied about the employee.

She admitted making the false VAT submissions and said it was initially a genuine mistake but continued making the false claims to keep the money with the intention of repaying HMRC once the business was in better financial health.

She paid the VAT after HMRC launched a criminal investigation and uncovered the fraud.

“She shamelessly tried to blame an entirely innocent employee.

“Noble only paid the tax due when she became subject to a criminal investigation.”

He added: “We will ensure the honest majority are not cheated by tax fraudsters, like Noble. Anyone with information about tax fraud can report it to HMRC online or call us on 0800 788 887.”

Noble admitted the fraud at Liverpool Magistrates Court on September 4, 2018. She was sentenced to 16 months in jail, suspended for two years, at Liverpool Crown Court. And also ordered to complete 80 hours of unpaid community work with a 10-day Rehabilitation Activity Requirement.

The full amount owed to HMRC has now been repaid.