ScaffPlan is a revolutionary 3D modelling solution built to resolve many problems that take place in the high-risk scaffolding sector.

Founder of ScaffPlan, Simon Boyes is also the owner of Benchmark Scaffolding and has worked on some of Australia’s highest-profile scaffolding contracts.

“There are a lot of moving parts that happen running a scaffolding business, and I have tried just about every solution on the market to help reduce the stress and hassles, but there was nothing that was the full package to easily design and engineer scaffolding with accurate gear lists and live sharing”, Boyes said.

Initially, Boyes developed ScaffPlan for internal use in his business, however, soon discovered that the need for the product was much larger than he ever could have anticipated.

Earlier this year ScaffPlan launched in Australia and New Zealand, and in rapid succession, ScaffPlan’s international release followed within three months.

Boyes added “Being recognised on the global stage for our product is a huge step for us. We have the best team of people working to make ScaffPlan the best design program for scaffolders on the market. ScaffPlan has won its first global award but it won’t be the last.

Our program is getting better all the time and we are excited to work towards supporting the scaffold and construction industry with ScaffPlan. There is much, much more to come.”

ScaffPlan’s solution is one that enables any scaffolding, construction, or engineering company to rapidly develop world-class scaffold designs in 3D, complete with automated safety features, engineering reports, virtual reality and instant collaboration with anyone.

We are seeing the rapid adoption of 3D software across the construction industry as organisations embrace the efficiencies of a paper-free approach by using modern technology, ScaffPlan is finally a way for scaffolders to easily follow suit.

ScaffPlan has been developed in synergy with industry-leading scaffolders, temporary works engineers, and a very talented team of software developers who have brought Simon’s idea into a product that can revolutionise and futurise scaffolding globally.

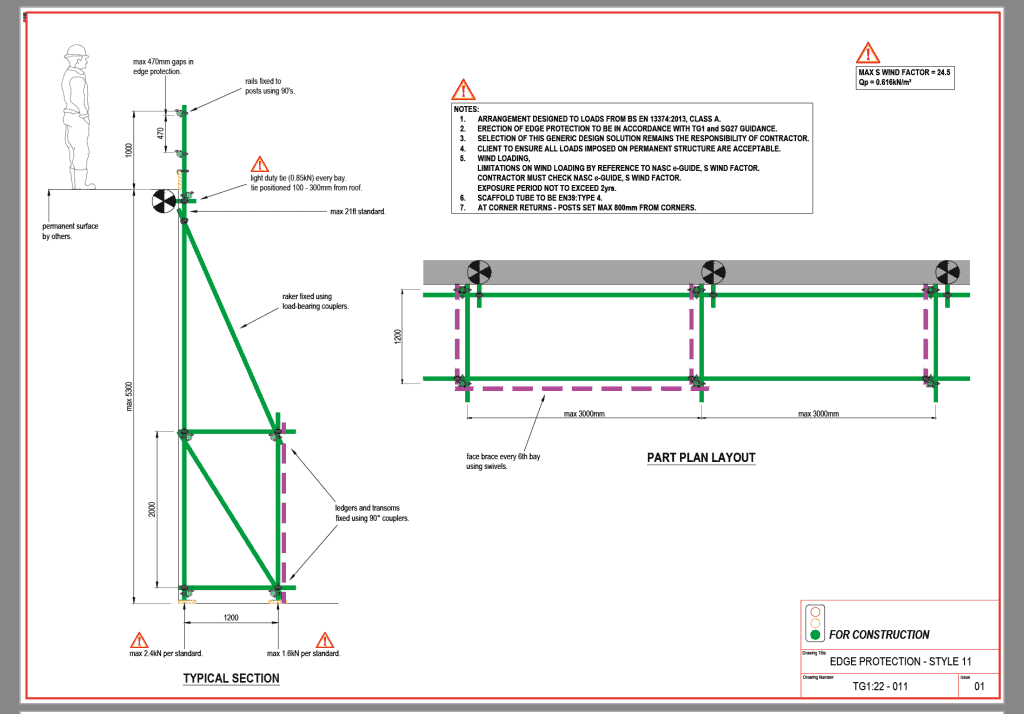

James Attridge, Director at JFE Attridge Scaffolding Services Co Ltd and Chair of the NASC Technical Committee, added: “The re-introduction of TG1 has been a long drawn out and complex procedure as all the Class A designs had to be CAT 3 checked and include wind loading which wasn’t taken into consideration in the previous guidance.

“Now that the first set of designs have been completed and approved, the testing for Class B loadings (taken from BS EN 13374) on all the Class A configurations will begin. The official testing is due to start later this year.

“Some basic preliminary tests (class B) on a couple of the designs have taken place and proved successful. When TG1:22 has been fully developed and added to the NASC ePortal, it will enable a compliance sheet to be produced from the suite of edge protection types similar to how a TG20:21 compliance sheet is produced for basic scaffolds.

“We’re sure this will be widely used by NASC Contractor members.”

TG1:22 is available to NASC members for free digital download via the

James Attridge, Director at JFE Attridge Scaffolding Services Co Ltd and Chair of the NASC Technical Committee, added: “The re-introduction of TG1 has been a long drawn out and complex procedure as all the Class A designs had to be CAT 3 checked and include wind loading which wasn’t taken into consideration in the previous guidance.

“Now that the first set of designs have been completed and approved, the testing for Class B loadings (taken from BS EN 13374) on all the Class A configurations will begin. The official testing is due to start later this year.

“Some basic preliminary tests (class B) on a couple of the designs have taken place and proved successful. When TG1:22 has been fully developed and added to the NASC ePortal, it will enable a compliance sheet to be produced from the suite of edge protection types similar to how a TG20:21 compliance sheet is produced for basic scaffolds.

“We’re sure this will be widely used by NASC Contractor members.”

TG1:22 is available to NASC members for free digital download via the

Hydrajaws’ first tester was prototyped in 1985 and has been manufactured and developed since 1986 by this family-run business, founded by Chairman Royston Morgan. Significant developments have taken place over the decades and not only to the base design, now with a capacity of 25kN.

Added to the range has been a wide range of adapters and accessories for fixing types from proprietary manufacturers plus additional product for specialised testing, delivering up to 500kN. The full range enables the testing of a simple plastic plug through to M36 heavy duty construction anchors. An important facet of the business is the testing of scaffolding anchor points where any potential for failure can have catastrophic consequences.

Since 2014, Hydrajaws has taken the lead in the digital world, being the first to

Hydrajaws’ first tester was prototyped in 1985 and has been manufactured and developed since 1986 by this family-run business, founded by Chairman Royston Morgan. Significant developments have taken place over the decades and not only to the base design, now with a capacity of 25kN.

Added to the range has been a wide range of adapters and accessories for fixing types from proprietary manufacturers plus additional product for specialised testing, delivering up to 500kN. The full range enables the testing of a simple plastic plug through to M36 heavy duty construction anchors. An important facet of the business is the testing of scaffolding anchor points where any potential for failure can have catastrophic consequences.

Since 2014, Hydrajaws has taken the lead in the digital world, being the first to

Toby Budd, MD and Founder said ”We started off with simple pontoons that could be used for access. Then we added outboard pods to the pontoons turning them into workboats, suddenly they became much more useful to our customers and now 90% of our hires go out as a ‘vessel’. We then added spud legs, deck winches, and other bolt-ons to add further value. But there is no doubt that it is the addition of a knuckle boom crane that marks the biggest advance in the system from an engineering perspective. Lifting is a key component for most marine works and I am delighted we can now offer this to our customers”.

The company is now developing a crane base for larger projects and expects to soon offer a 7tm crane on their larger 750mm beam system.

The ScaffFloat was on hire for almost two months to GPS MACS who are a specialist marine contractor on the Thames. The ScaffFloat package provided the perfect tool for the job, it also had the benefit of very low draft (just 0.3m) and could be dried out on the steep mud banks giving the workers a much larger tidal working window than more traditional vessels that would not have been able to ground out.

Ross Albertyn, project manager, said “Thanks again for your assistance on this project. The ScaffFloat has been absolutely brilliant.”

Toby Budd, MD and Founder said ”We started off with simple pontoons that could be used for access. Then we added outboard pods to the pontoons turning them into workboats, suddenly they became much more useful to our customers and now 90% of our hires go out as a ‘vessel’. We then added spud legs, deck winches, and other bolt-ons to add further value. But there is no doubt that it is the addition of a knuckle boom crane that marks the biggest advance in the system from an engineering perspective. Lifting is a key component for most marine works and I am delighted we can now offer this to our customers”.

The company is now developing a crane base for larger projects and expects to soon offer a 7tm crane on their larger 750mm beam system.

The ScaffFloat was on hire for almost two months to GPS MACS who are a specialist marine contractor on the Thames. The ScaffFloat package provided the perfect tool for the job, it also had the benefit of very low draft (just 0.3m) and could be dried out on the steep mud banks giving the workers a much larger tidal working window than more traditional vessels that would not have been able to ground out.

Ross Albertyn, project manager, said “Thanks again for your assistance on this project. The ScaffFloat has been absolutely brilliant.”

Ojay Roynon, Site Manager at Benchmark Scaffolding, said: “We used Powerclad’s flame retardant grade which is third-party certified as fully compliant for interior use. That is a vital attribute in maximising safety throughout the internal reconstruction.”

Jamie Lyons, Scaffold Health & Safety Advisor at Simian Risk, said: “The scaffolding has been installed to a high standard and ITP’s Powerclad FR sheeting certainly meets the performance and safety demands of this major redevelopment.”

ITP Account Manager, Seb Carrick, said: “Our Powerclad FR sheeting has an advantage over many rival products because the system’s fire safety attributes make it suitable for both internal and external site application. We manufacture plain, flexographically printed and digitally printed sheeting which is approved under Certifire T62 for external installation and Certifire T63 for internal installation. Having both of those certifications within the same product is currently unique in the UK market. All our Powerclad FR systems are independently tested and have a Euroclass rating of B-s1,d0 EN 13501-1.”

The redevelopment of the BT Centre will improve the environmental performance of the building and minimise environmental impact by reusing its original Portland stone, employing modular construction methods, specifying low carbon materials and adopting a zero to landfill policy. The project aims to deliver a building which is air quality neutral, providing one of the highest ‘urban greening factors’ in London and to be the first net zero carbon enabled office development in London.

Ojay Roynon, Site Manager at Benchmark Scaffolding, said: “We used Powerclad’s flame retardant grade which is third-party certified as fully compliant for interior use. That is a vital attribute in maximising safety throughout the internal reconstruction.”

Jamie Lyons, Scaffold Health & Safety Advisor at Simian Risk, said: “The scaffolding has been installed to a high standard and ITP’s Powerclad FR sheeting certainly meets the performance and safety demands of this major redevelopment.”

ITP Account Manager, Seb Carrick, said: “Our Powerclad FR sheeting has an advantage over many rival products because the system’s fire safety attributes make it suitable for both internal and external site application. We manufacture plain, flexographically printed and digitally printed sheeting which is approved under Certifire T62 for external installation and Certifire T63 for internal installation. Having both of those certifications within the same product is currently unique in the UK market. All our Powerclad FR systems are independently tested and have a Euroclass rating of B-s1,d0 EN 13501-1.”

The redevelopment of the BT Centre will improve the environmental performance of the building and minimise environmental impact by reusing its original Portland stone, employing modular construction methods, specifying low carbon materials and adopting a zero to landfill policy. The project aims to deliver a building which is air quality neutral, providing one of the highest ‘urban greening factors’ in London and to be the first net zero carbon enabled office development in London.