Scaffolding firm provides unique service to Emirates Stadium

Royston Scaffolding Ltd has completed specialist confined space scaffolding works on the famous 60,000 seater Emirates Stadium, despite being Spurs fans.

The Cambridge & Hertfordshire based firm was commissioned by EOn to erect confined space scaffolding to the home of the Arsenal Football Club. The scaffolding was erected in an enclosed area underneath the stadium that allowed engineers to work on the power supply in various areas. Since becoming skilled in confined-space scaffolding over three years ago Royston Scaffolding Ltd has seen growth in a number of these unique projects, they said. Despite both business partners being life long Tottenham Hotspurs supporters Eliott McGrath and Craig Nettleingham were still eager to take one and complete this project. Managing director Elliott McGrath commented: “While we, of course, we were always going to take the project on, we did take an extra second to think about it! Since moving into confined space scaffolding though we have been able to diversify our services as well as increase our extensive scaffolding knowledge”.

Scaffolding in confined spaces can be very demanding and working conditions are often hazardous to workers, therefore companies have very specific high standard requirements with lots of planning and processing the scaffold involved throughout construction to meet an essential high standard of safety.

McGrath added: “What we didn’t take into account was that the work began the day after the North London derby where Spurs lost 4-2! Talk about rubbing salt in the wounds! The fans of the ‘other’ North London club can rest assured nothing was tampered with.”

Managing director Elliott McGrath commented: “While we, of course, we were always going to take the project on, we did take an extra second to think about it! Since moving into confined space scaffolding though we have been able to diversify our services as well as increase our extensive scaffolding knowledge”.

Scaffolding in confined spaces can be very demanding and working conditions are often hazardous to workers, therefore companies have very specific high standard requirements with lots of planning and processing the scaffold involved throughout construction to meet an essential high standard of safety.

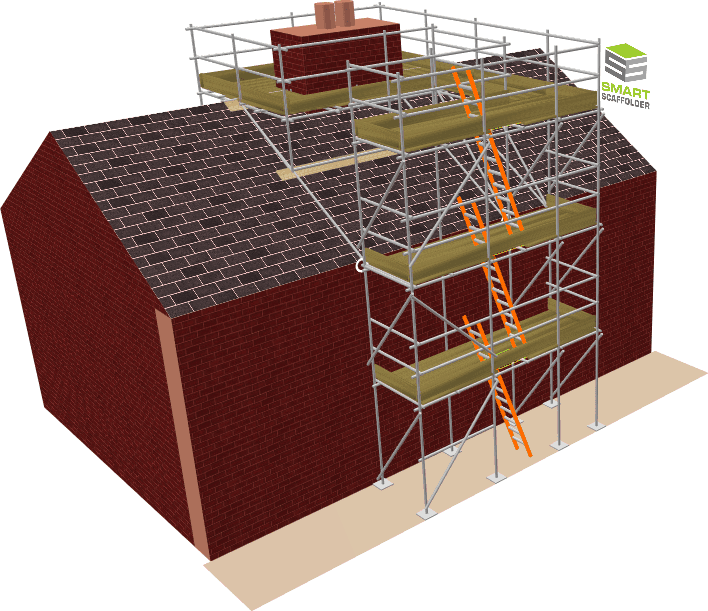

McGrath added: “What we didn’t take into account was that the work began the day after the North London derby where Spurs lost 4-2! Talk about rubbing salt in the wounds! The fans of the ‘other’ North London club can rest assured nothing was tampered with.” SMART Scaffolder launches new update to Handover App

Scaffolding software developers SMART Scaffolder have launched a mobile app to track variations.

SMART Scaffolder Software has a full programme of product development in 2019, adding functionality to both their market leading design, estimating and TG20:13 compliance software ‘SMART Estimator’ and to their mobile apps: SMART Inspector and SMART Handovers! SMART Scaffolder Software launched their SMART Handovers mobile app to streamline and automate the issuing of Handover Certificates and to ensure extra hire was always logged and billed. They recently made this app even more useful by adding the ability to record variations. The ability to add photos and a digital signature means any possible disputes over what, when and by whom instructions were issued are resolved more quickly and easily than ever before. A simple to use ‘web console’ gives managers clear reports including sites that are on hire, variations requested and the percentage built while banishing the need for paper forms that need to be rekeyed at best or lost at worst. Commenting on the update Ian Chambers, Sales and Marketing Director at SMART Scaffolder, said: “having the ability to track what scaffolds are on hire in one console gives a great overview and this new functionality clearly logs any variation requests and ensures all work is invoiced appropriately”.

According to the firm, when the apps are combined with the existing powerful functionality of SMART Estimator scaffolders have the most powerful and comprehensive business management software scaffolders can buy.

To see more details, visit the SMART Scaffolder website.

Commenting on the update Ian Chambers, Sales and Marketing Director at SMART Scaffolder, said: “having the ability to track what scaffolds are on hire in one console gives a great overview and this new functionality clearly logs any variation requests and ensures all work is invoiced appropriately”.

According to the firm, when the apps are combined with the existing powerful functionality of SMART Estimator scaffolders have the most powerful and comprehensive business management software scaffolders can buy.

To see more details, visit the SMART Scaffolder website. Scaffolding Finance In The 21st Century

Scaffolding and construction companies across Britain are a credit to the UK economy in so many ways. They provide much-needed services and skill-sets, and a busy firm is certainly a happy one. Businesses don’t run themselves of course, and whether large or small it can be difficult getting the right financial support.

Crucial Help And Guidance

Many companies need the help and guidance of specialist financial setups like Minaur Corporate Finance Ltd, MCF, who can offer bespoke finance for the scaffolding market – Scaffolding contractor funding lines. Why use such a service? Because by utilising such assistance can prove invaluable when it comes to acquiring additional scaffolding, plant, vehicles, or Loans for surfacing yards, marketing campaigns, website development, working capital or even spreading Tax, VAT and Insurance bills.Helping The Industry

Paul Minaur, MD, said, “We also have up to £100,000 facilities available for companies where the directors are tenants rather than personally homeowners, which is helping to support a large and underfunded sector of businesses. “At MCF, we have helped companies in the construction industry that have significant amounts of money tied up in unpaid invoices. Using a range of privately-owned funders you can release the majority of invoice values immediately freeing tied up cash via Factoring and Invoice Discounting facilities.” “Many of our customers wrongly believe these facilities can’t work for them as they issue applications for payment rather than invoices. This is not the case. Facilities are available for applications for payment and contract payment terms.” Tax efficient facilities through lease, hire purchase, unsecured loans as, well as debt finance/factoring and invoice discounting are used by companies of all sizes. There’s also specialist software available to help make life much easier for those in the industry. Freeing up much-needed cash flow can also save priceless time, and help any business run more efficiently.Finance Facilities

MCF, have provided Scaffolding and Construction companies with a range of different finance facilities to support their businesses since 1999, and have won several awards from Funders for the services they provide. Their personal approach and efficient service has gained them many new friends and contacts along the way. Paul added: “Whether you are just starting out or a long-established organisation, make sure that you have looked at all the options before committing.” “For more information on your specific requirements please contact MCF for a confidential conversation on what we can achieve for you.” https://www.m-c-f-ltd.co.uk/Scaffolder falls five meters through skylight

A scaffolder sustained life-changing injuries after falling through a 5-meter high skylight fracturing his pelvis, elbow, wrist, and arm.

Poole Magistrates court heard how scaffolder Paul Norris (49) was completing work for the company Solar Scaffolding Services Limited who were contracted to erect an access tower and guard rails around the roof of some industrial units on 10th April 2017. While assisting colleagues with the guard rails, Norris gained access via the roof then fell through a skylight 5 meters to the ground. He was hospitalised for three weeks and had to undergo many surgeries and ongoing physiotherapy as a direct result of the accident. When investigated by the HSE Solar Scaffold Services were found to have failed to take appropriate measures to prevent a fall through the fragile roof and that as an employer their duty to ensure that the work at height was adequately planned, supervised and carried out safely had failed. A guilty plea was heard in court form the company after they were found to have breached the Work at Height Regulations 2005. Solar Scaffolding Services Limited was fined £10,000 and ordered to pay £3,666.80 in costs. The courts also heard how Norris is now registered disabled and his wife has had to give up work to provide care for her husband. He has also had to move out of his home and move into an adapted flat and can no longer return to work. HSE Inspector Caroline Penwill commented on the hearing, “Falls from height remain one of the most common causes of work-related fatalities and injuries in this country and the risks of working with heights are well known. Mr. Norris’s injuries were life changing for both him and his family. He could have easily been killed. This serious incident could have been avoided if the work had been properly planned to reduce the risk”.Construction Industry Helpline provides £1.254 million of charitable support to the industry.

In construction, many workers and their families can find themselves in a desperate situation and are unsure of who to turn to for help and advise.

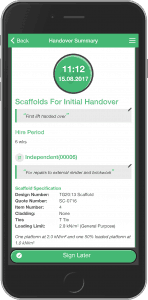

This is where the inspirational charity The Lighthouse construction charity can help. The charity provides financial and emotional support to the construction community and their families who are suffering from the effects of long term illness, injury or financial difficulties. They offer support to anyone who needs advice on debt management, taxation or just generally need a helping hand in life. A recent press release from Lighthouse has shown some staggering statistics on the emotional welfare of construction workers in the UK and Ireland. 2018 was a difficult year for many people and for many reasons but in the construction industry last year alone 1662 individuals or families in crisis contacted the Lighthouse helpline. These calls ranged from mental health issues to legal, taxation and debt management advice. The financial support provided in 2018 by Lighthouse was £1.25 million a staggering increase of 75% compared to 2017. Lighthouse Construction Industry charity provides helpline packs to employers and construction employees and thus far have a total of 350,000 helpline cards in circulation within our industry. The charity has also recently launched a helpline app with the support of construction software ‘COINS’, the app enables industry workers and their families to quickly and conveniently find out more information on self-help techniques or how to progress to the next step in seeking professional help. This app is designed to be a preventative tool that can be used in the early stages of a situation to prevent a crisis for the individual by seeking help quicker.

For help on downloading this app please visit their page here

Lighthouse provides a 24 hour 7 days a week confidential helpline, 0345 6051956, which presents the first step in getting help and support on the situations many construction workers may be facing.

Working closely within the industry and with the individual employers, Lighthouse offers an online portal of information about mental health, equipping employers with the knowledge and skills to begin developing the process of a positive mental health culture in their workplace.

For more information please visit: https://www.buildingmentalhealth.net/

To encourage the shift in attitude towards mental health Lighthouse empowers employers by providing downloadable videos and toolbox talks as well as essential advice on how to access health training and services.

All of this information is free of charge and can be tailored to the individual companies needs.

The charity has also recently launched a helpline app with the support of construction software ‘COINS’, the app enables industry workers and their families to quickly and conveniently find out more information on self-help techniques or how to progress to the next step in seeking professional help. This app is designed to be a preventative tool that can be used in the early stages of a situation to prevent a crisis for the individual by seeking help quicker.

For help on downloading this app please visit their page here

Lighthouse provides a 24 hour 7 days a week confidential helpline, 0345 6051956, which presents the first step in getting help and support on the situations many construction workers may be facing.

Working closely within the industry and with the individual employers, Lighthouse offers an online portal of information about mental health, equipping employers with the knowledge and skills to begin developing the process of a positive mental health culture in their workplace.

For more information please visit: https://www.buildingmentalhealth.net/

To encourage the shift in attitude towards mental health Lighthouse empowers employers by providing downloadable videos and toolbox talks as well as essential advice on how to access health training and services.

All of this information is free of charge and can be tailored to the individual companies needs.

Bill Hill, CEO of the Lighthouse Construction industry charity commented on the recent figures released, “On the positive side the 2018 figures show that we are reaching out to more construction workers and their families, but it also means that too many of them find themselves in desperate situations. The significant escalation in families needing our support has taken us by surprise and has put pressure on our finances.

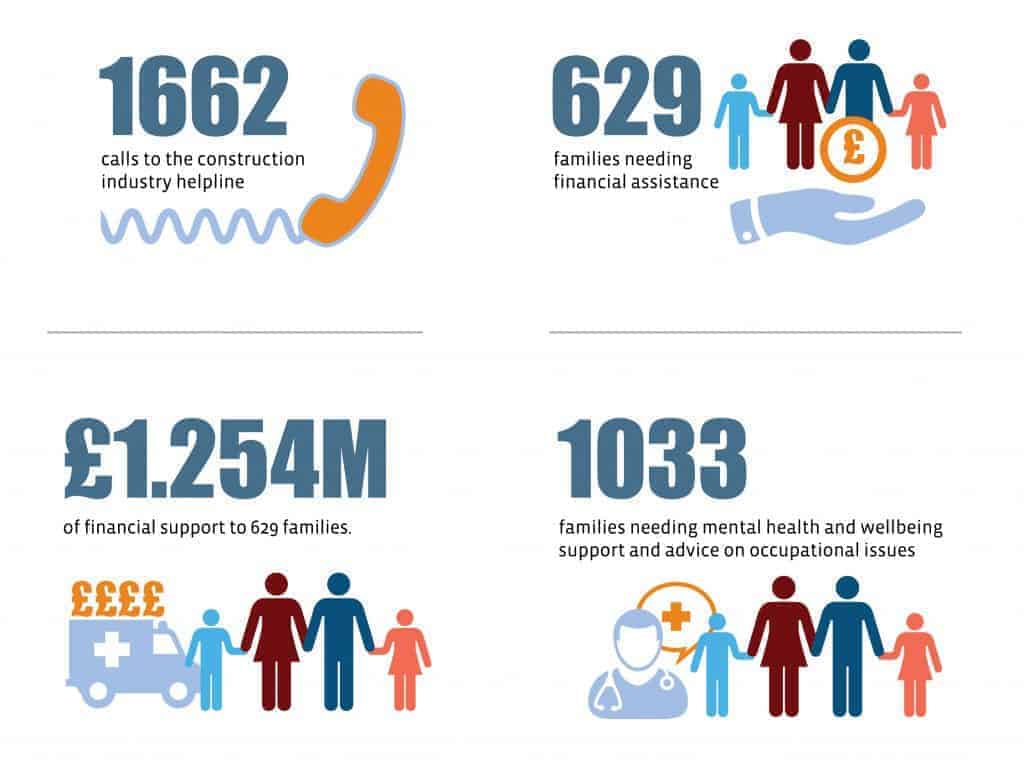

With two construction workers taking their own lives every single working day, and stress depression and anxiety accounting for a fifth of all work-related illness it is vital that we continue to provide our helpline services and put additional funding into the construction industry’s dedicated volunteer-led building mental health programme.”

It is important to stress that Lighthouse is a charity based organisation helping thousands of industry workers and their families on a daily basis, Lighthouse receives no public funding and relies solely on the generosity of those working within the industry to help them continue their vital, life-changing work.

Hill added, “The only way we can plan ahead is with predictable income. That’s why we have launched our company supporters initiative and our ‘save a life’ campaign. We are urging companies to pledge a regular annual donation to ensure the long term sustainability of our valuable charity services.

If you are reading this and wondering how your company can make a difference, then here’s how to get involved.”

https://www.lighthouseclub.org/lighthouse-company-supporter/

Bill Hill, CEO of the Lighthouse Construction industry charity commented on the recent figures released, “On the positive side the 2018 figures show that we are reaching out to more construction workers and their families, but it also means that too many of them find themselves in desperate situations. The significant escalation in families needing our support has taken us by surprise and has put pressure on our finances.

With two construction workers taking their own lives every single working day, and stress depression and anxiety accounting for a fifth of all work-related illness it is vital that we continue to provide our helpline services and put additional funding into the construction industry’s dedicated volunteer-led building mental health programme.”

It is important to stress that Lighthouse is a charity based organisation helping thousands of industry workers and their families on a daily basis, Lighthouse receives no public funding and relies solely on the generosity of those working within the industry to help them continue their vital, life-changing work.

Hill added, “The only way we can plan ahead is with predictable income. That’s why we have launched our company supporters initiative and our ‘save a life’ campaign. We are urging companies to pledge a regular annual donation to ensure the long term sustainability of our valuable charity services.

If you are reading this and wondering how your company can make a difference, then here’s how to get involved.”

https://www.lighthouseclub.org/lighthouse-company-supporter/ Young scaffolder who struggled with depression found hanged by mum

The heartbreaking news of a young scaffolder who committed suicide has been released.

An inquest at Bradford coroner court heard how Louie Sam Bates (19) from Halifax was found by his mother suspended from a ligature in their family home. Bates had been suffering from depression for two years but tragically had not pursued any help for his condition, the courts heard. The coroner court also heard how Bates lived with his Mother Lisa Mullally and his younger sister, he was last seen by his grandmother asleep in bed between 6:30pm and 7pm on Saturday 5th January, a message was then received by Louie’s partner sent from his sisters phone at 5:30 am the following day. Coroners official Bernard Tate stated that, after being found by his mother, Bates was placed on the living room floor and his death was confirmed by paramedics at 10:02am. Oliver Crouch, a friend of Mr Bates has set up a gofundme page in memory of Louie with the aim of raising £1000. The generosity of Louie’s friends and family have far surpassed the expectation and have so far raised a fantastic £8580 in ten days. To date, 481 friends and family members have donated showing fantastic support for this ‘Top lad’ and his family. The amounts donated range from £5 to a generous £1000 from KLN Scaffolding. To donate to Louie Bates fund please visit the gofundme page Mental Health effects everybody at some point in their lives with an estimated one in four people affected every year. With the unnecessary stigma attached to mental health issues, some people can find it very difficult to muster up the courage to access help. A new campaign was set up in 2018 by the NASC called Head For Heights in a bid to assist sufferers of mental health in the construction industry to have more confidence to discuss their issues and help them to identify who they can talk too. In the construction industry, it is believed the macho and male-dominated nature of the workplace can inhibit mental health sufferers to discuss their condition and this alone can exacerbate their troubles and become more harmful to the individual than the condition itself. Sadly, in a study published by Lexology, construction site workers are three times more likely to commit suicide than the average UK male.Where to get help.

It is important to remember you are not alone, there is help available to you if you are feeling symptoms of mental illness such as anxiety depression or low mood. Don’t suffer in silence, some organisations you can access if you need help or just wish to speak to someone anonymously and in confidence are:- Lighthouse Club: lighthouse club Construction Industry Helpline 0345 605 1956

- Samaritans: phone 116 123, 24 hours a day or you can email [email protected]

- Campaign Against Living Miserably (CALM): For young men who are feeling unhappy, phone 0800 58 58 58

- Time to change: www.time-to-change.org.uk

- Bullying UK: Bullying UK A website for both adults and children who are affected by bullying.

No fear scaffolders dismantle high altitude hanger

Video showing scaffolders dismantling a high altitude scaffold posted by ScaffMag goes viral with 2.5 million views on Facebook.

The location of where the video was taken is unknown but many commenting on the video posted on Monday said how queasy they felt watching the 60-second clip. The nail-biting film shows two scaffolders removing the high scaffold from the side of an unknown building. If that wasn’t bad enough a worrying fault was spotted with the scaffolders harnesses, no retrievable inertia reel is being used and their anchor points are quite questionable, to say the least.Council guilty after worker crushed by pack of roof trusses

Darlington Borough Council has been fined £28K after a labourer was injured when a pack of roof trusses fell on him.

Newton Aycliffe Magistrates’ Court heard how, on 5 October 2017, the self-employed labourer was working for two brickies sub-contracted to Darlington Borough Council. He was walking past the front of the building plot at Allington Way, Darlington, when a pack of roof trusses fell on him, trapping him by the head and arm. An investigation by the Health and Safety Executive (HSE) found there was an overall failure to adequately monitor work activities at the site at Allington Way, Darlington. Contributing factors to the incident included inadequate arrangements for the storage of roof trusses, failure to manage the amount of materials on site, failure to plan for parking of vehicles on site and poor housekeeping on site. Darlington Borough Council of Town Hall, Darlington pleaded guilty to breaching the Construction (Design & Management) Regulations 2015 and has been fined £28,000 with £1,648.45 in costs. Speaking after the hearing, HSE inspector Andrea Robbins said: “It is vital that work activities on construction sites are properly planned, managed and monitored to prevent issues like this developing on site – the failures found here ultimately led to the roof trusses falling onto the labourer, causing serious injuries. This could have been prevented.”New Stay Safe at Height training course announced by CISRS

CISRS have announced they are introducing a new Stay Safe at Heights Scaffold Awareness course. The one day course will be open to tradesmen and construction workers such as bricklayers, painters and electricians.

CISRS say delegates will have a better understanding and appreciation of the core components of a safe scaffold and will be able to identify the potential dangers of working at heights from a scaffold platform.

Upon completion of this course delegates will receive a CISRS scaffold awareness certificate.

The NASC has welcomed the introduction of the course, NASC Health and Safety advisor Stephen Allen-Tidy stated, “The NASC is committed to promoting the highest standards of safety within the industry. Through the publication and dissemination of a wide range of industry recognised safety and technical guidance including SG4:15 Preventing Falls in scaffolding operations, we continue to drive safety standards upwards.”

The course will be beneficial to anyone who works at height in any place, and as the Work at Heights Regulations 2005 state, ‘employers must ensure all employees engaged in any work at height activity must be competent to do so.’

Statistics presented in the NASC 2018 Safety report show that the number of falls from heights accidents has decreased by 46% from 26 to 14 in 2017.

CISRS Administrator, Laura Weekes commented, “This classroom-based course will give tradesmen a basic understanding of what a compliant scaffold looks like and guidance on how they can work at heights safely. We are looking to offer this course at training centres nationwide from this summer onwards.”

Stephen Allen-Tidy added, ”Through the introduction of the Scaffolding Awareness training course the scope of safety training efforts is being extended beyond scaffolding operatives, helping to ensure that all workers who set foot on a scaffold can carry out the tasks they require safely.”