Scarborough-based Infiniti Scaffolding has been awarded a ‘high six-figure’ contract on the coastal resort’s Esplanade Hotel for the Daish Hotel Group.

The company is currently erecting access scaffolding, renewing the interior, exterior and roof on the hotel refurbishment project.

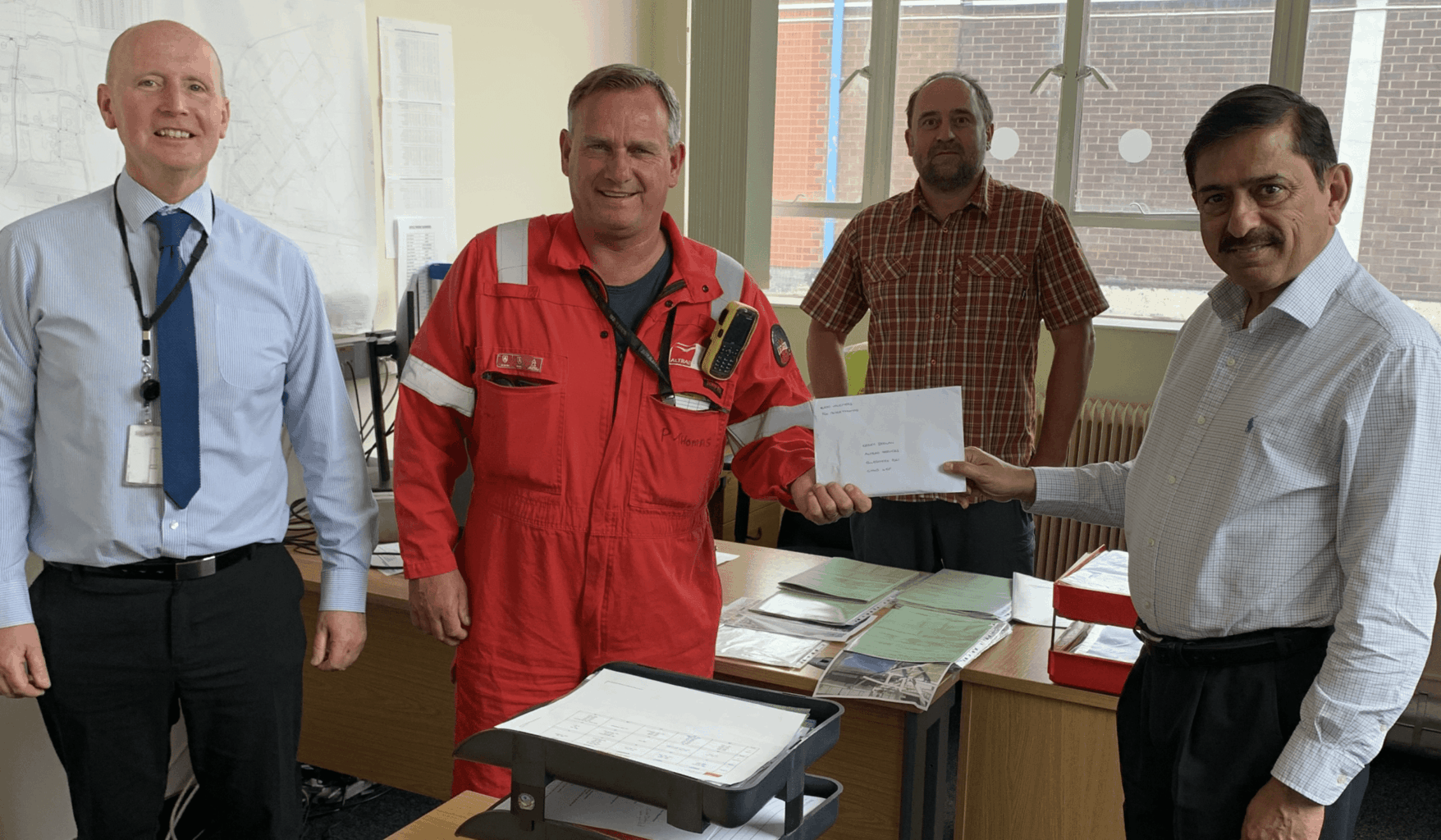

Infiniti Scaffolding which is part of the Infiniti Group has also just completed three, six-figure sum scaffolding and re-roofing contracts for Department of Work and Pensions (DWP) office blocks in Grimsby, Leeds and Norwich.

Work on the Victorian Esplanade Hotel has already begun and will create jobs for between 15 and 20 Infiniti Group employees and sub-contractors throughout the contract which is due to be completed by the end of March, 2021.

With scaffolding erected during October and November work has now commenced on construction. This will include: re-roofing the five-storey hotel with 15,000 traditional slates over a 440m sq area; the full refurbishment of 12 of the Esplanade’s 73 bedrooms and bathrooms; installation of a new women’s toilet; external painting of all walls and window wood works, including more than 200 sash windows; and redoing the external walkways.

“This is the second high profile hotel refurbishment we have won in Scarborough and follows the conversion of The Mount Hotel into the Bike & Boot Hotel. The Esplanade is an amazing building with a wonderful location and will be a fantastic place for us to work,” said Alex Willgrass, Infiniti Group director.

“The Esplanade and other important works for the DWP confirm our status as one of the leading scaffolding, construction and building services companies in Yorkshire and the North of England.”

Part of Infiniti Group’s success derives from how it has managed to win and successfully complete contracts during the Covid-19 pandemic and lockdown.

Marcus Rowe, Infiniti Group director, said: “There are some clear logistical and construction challenges ahead of us posed by lockdown, Brexit and the hotel’s location.

“However, we’ve shown that Infiniti Roofing & Construction is more than capable of dealing with the operational impact of the Covid-19 lockdown and coping with the stringent social distancing measures required.”

The company will pre-empt any further Covid-19 lockdowns by buying the majority of the materials they need to finish the work, while also sourcing additional fully experienced, available, skilled contractors.

Covid social distancing safety will be achieved using signage, floor and wall markings, Hi-Viz and intelligent clothing and exact, pre-planned operational movements of workers around the site, such as keeping contractors separate and adopting work patterns sequentially across the hotel’s floors.

Infiniti Group’s contracts manager, Sharon Lester, said: “Brexit is also an issue as, potentially, we’re faced with delays related to specialist supplies being brought in from mainland Europe inlcuding a new 4,000-litre water tank.

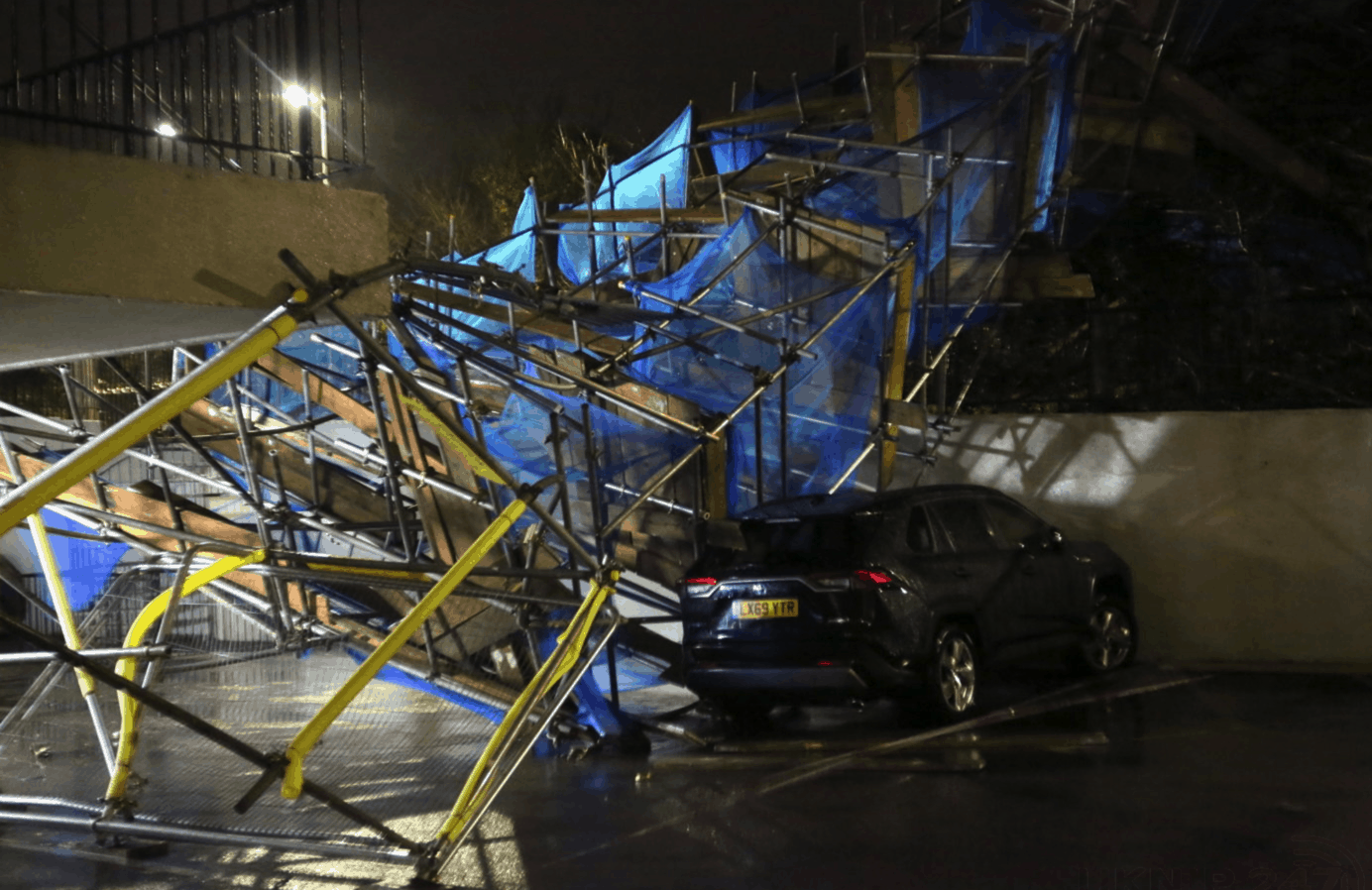

“And then there’s the weather – on the highest parts of the hotel exposed to the North Sea our workers and contractors will have to contend with sometimes extreme winter working conditons including very strong winds.”

Infiniti Group’s three DWP contracts, for Mitie Group, the facilities management and professional services company, include all scaffolding works and a full Sika Liquid Plastics roof system installed at DWP offices in Grimsby, Leeds and Norwich.

Greg Forster, MD at Embrace, said “Together with our two organisations respect the environment and are always on the lookout for fresh innovative solutions. The distinctive design on the wrap is pixel-perfect, masking the scaffold whilst maintaining a delightful streetscape for the community during the build. We lead, others follow!”

As a business Embrace continue to investigate ways to protect the environment and reduce waste, having started off in 2017 with the unique Banner Karma initiative for upcycling clients’ spent solid PVC banners into the agricultural sector.

Embrace is now able to offer clients PVC-free printed building and scaffold wraps. The goal is to reduce reliance on PVC and move to more sustainable printable media solutions as the sector’s leader in environmental positivity.

Successful in-house testing has been concluded on print quality to ensure that the material delivers the same visual appearance & manufacturing process with heat and vibration welding. To ensure the structural integrity of the material Embrace have conducted pull tests to ensure that the material is robust.

The results were that the PVC-free banners can withstand up to 774 kg on average, suitable for the considerable stresses Mother Nature throws at their bespoke installs over the four seasons.

The materials have passed fire tests reports in the UK with SGS a UKAS certified fire test centre for both in its natural state off the roll and with cured inks to BS 5867 Type B. The manufacturer of the eco-friendly Kavalan textile also has supporting fire test reports to the EN13501-1 and DIN 4102-1 standard.

The PVC-free banners are suitable for indoor and outdoor use as a solid flexible print substrate, constructed from a 56% polyester scrim and a 44% PA water-based coating. The great news is that Embrace will still send the material to be repurposed and then – even when the second life of the wrap is over – the material can be sent for energy-from-waste disposal.

Embrace Building Wraps:

Greg Forster, MD at Embrace, said “Together with our two organisations respect the environment and are always on the lookout for fresh innovative solutions. The distinctive design on the wrap is pixel-perfect, masking the scaffold whilst maintaining a delightful streetscape for the community during the build. We lead, others follow!”

As a business Embrace continue to investigate ways to protect the environment and reduce waste, having started off in 2017 with the unique Banner Karma initiative for upcycling clients’ spent solid PVC banners into the agricultural sector.

Embrace is now able to offer clients PVC-free printed building and scaffold wraps. The goal is to reduce reliance on PVC and move to more sustainable printable media solutions as the sector’s leader in environmental positivity.

Successful in-house testing has been concluded on print quality to ensure that the material delivers the same visual appearance & manufacturing process with heat and vibration welding. To ensure the structural integrity of the material Embrace have conducted pull tests to ensure that the material is robust.

The results were that the PVC-free banners can withstand up to 774 kg on average, suitable for the considerable stresses Mother Nature throws at their bespoke installs over the four seasons.

The materials have passed fire tests reports in the UK with SGS a UKAS certified fire test centre for both in its natural state off the roll and with cured inks to BS 5867 Type B. The manufacturer of the eco-friendly Kavalan textile also has supporting fire test reports to the EN13501-1 and DIN 4102-1 standard.

The PVC-free banners are suitable for indoor and outdoor use as a solid flexible print substrate, constructed from a 56% polyester scrim and a 44% PA water-based coating. The great news is that Embrace will still send the material to be repurposed and then – even when the second life of the wrap is over – the material can be sent for energy-from-waste disposal.

Embrace Building Wraps:

He added: “The housebuilding sector remains buoyant with support measures due to continue into the first quarter of 2021 and the government is committed to new infrastructure spending.”

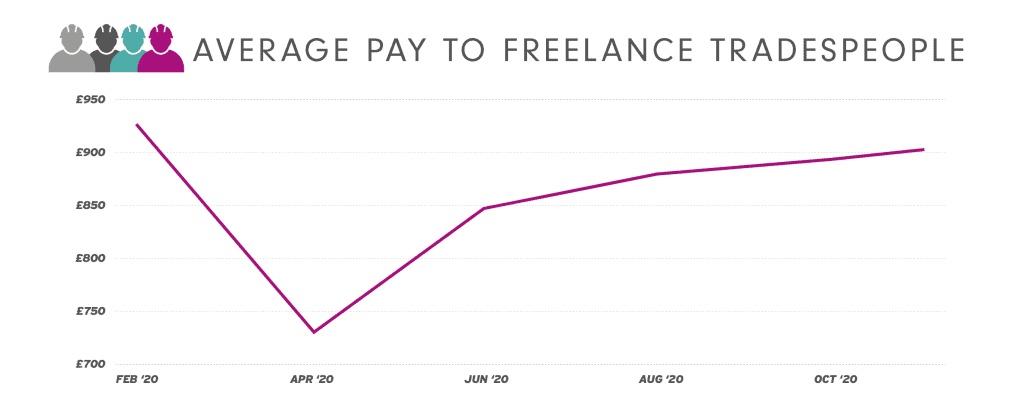

Mr Anfield said that demand for labour on building sites has flattened off at 90% of pre-Covid levels.

The recovery in demand which started in the summer “reached the top of the V” in November, he said, and is now in a seasonal cycle ahead of the festive period.

He added: “The housebuilding sector remains buoyant with support measures due to continue into the first quarter of 2021 and the government is committed to new infrastructure spending.”

Mr Anfield said that demand for labour on building sites has flattened off at 90% of pre-Covid levels.

The recovery in demand which started in the summer “reached the top of the V” in November, he said, and is now in a seasonal cycle ahead of the festive period.