GKR Scaffolding scoops top construction award

Scaffolding and access specialists GKR Scaffolding has won the Construction News Health, Safety & Wellbeing Excellence award.

The multi-award-winning business based in London picked up the accolade via an interactive virtual award ceremony, hosted by comedian Tom Allen and Construction News editor Lem Bingley.

The Construction News said GKR had taken behavioural training and wellbeing to the next level by identifying the cultural flaw that hinders people’s ability to learn and drive continuous improvement in safety.

Their award entry focussed on the firm’s cultural drive to improve psychological safety with its ‘Speak Up’ campaign.

The company’s internal initiative encourages high performing teams to record making more mistakes, including in safety, which they can openly learn from. The high levels of trust also mean GKR’s staff are comfortable sharing ideas. It is also the foundation for better mental health at work due to providing openness, support and involvement within the business.

GKR has said they are in the process of training all supervisors and managers in how to integrate psychological safety into their management styles.

GKR Strategy Director, Helen Gawor said: “The elephant in the room is that we have a blame culture in construction. The stifles our ability to learn how to work safer as people fear speaking up. This environment does nothing to support our mental health either.

Training staff to manage people in a way that creates trust and psychological safety means overcoming the outdated leadership styles connected with authority that we still see too often in our industry.

There is little point promoting wellbeing, safety and innovation initiatives unless we fix our culture.”

The Construction News judges commented: “This was an excellent submission, detailing how initiatives can drive change within an organisation. As a scaffolding company providing a service to principal contractors, GKR has continued to evolve and give health, safety and wellbeing all the same billing. In addition, the judges were impressed by the excellent commitment to training and development for staff and can see the impact this is having on the culture of the business.”

An Agile Approach to Health & Safety with Site Supervision

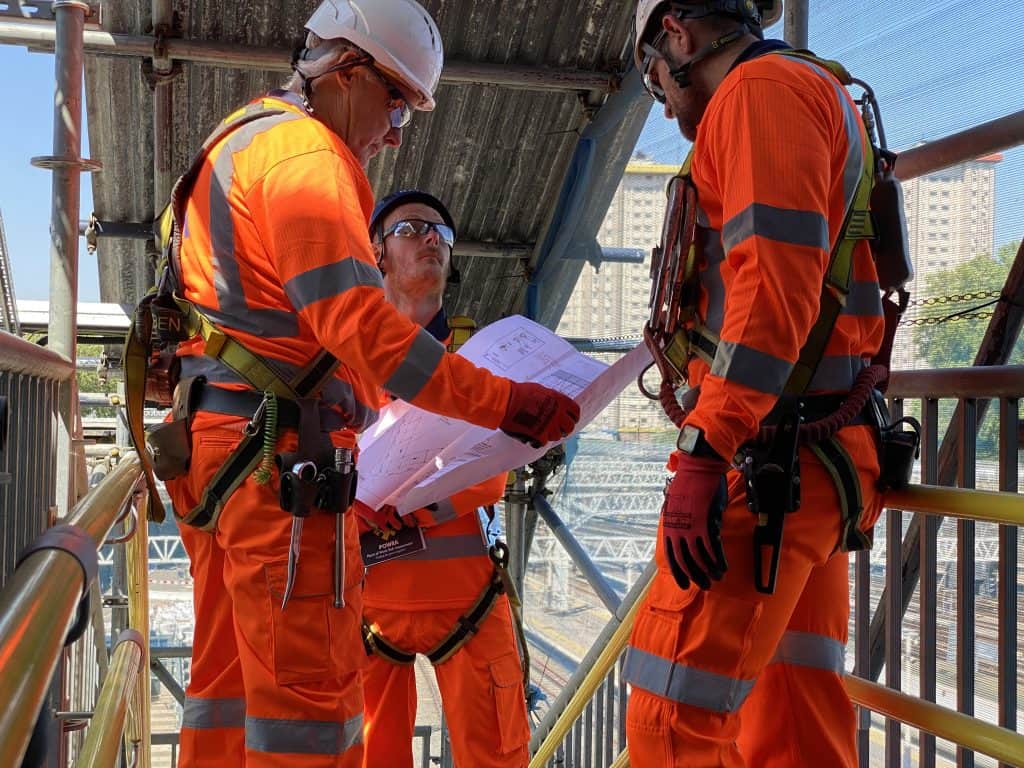

Billy Jones, Director of scaffolding company, Millcroft, discusses the importance of supervision in ensuring site risks are addressed in real-time and health and safety is maintained.

A meticulous approach to health and safety is integral to the success of any scaffolding business because the industry carries inherent hazards which must be managed effectively to reduce risk to employees, clients, delivery partners and the public.Embedding Supervision in a Team Approach

Health and safety is embedded in each project long before the installation takes place on site. The expertise of the design team, the maintenance of scaffolding materials, the safety of vehicles and the training of personnel all have a role to play in delivering safety and reducing risk. Health and safety measures are designed into the scaffolding solution and the risk assessment and method statement consider all potential health and safety issues so that hazards can be controlled. Once the project is on-site, however, risks can change. There may be changes to the scope of work, revisions to staffing, challenging weather conditions, factors relating to other trades…one of the only certainties about risk is that it is never static, so a project team needs to be prepared to adapt. As a result, the risk assessment carried out at the beginning of the project may not always be sufficient to anticipate risk throughout the programme, because new hazards can become apparent as the job progresses. It’s for these reasons that Millcroft decided some time ago to shift the Site Supervisor role from a desk-based responsibility, visiting sites daily and returning to the office to review works, to a site-based responsibility within the Foreman’s role. The move means that site-specific risk assessments and method statements can be updated in real-time in response to any changes to workplace conditions. The Foreman is responsible for identifying and managing risk on-site as part of a collaborative health and safety process which also includes the wider Millcroft team. Careful planning includes input from both the SHEQ and transport departments to co-ordinate safety on-site and efficient planning of materials, routes and vehicle allocation. Monitoring of projects by Millcroft’s managers and contracts managers, alongside regular director visits, audits and safety walk rounds, ensures every site is checked and scrutinised by a full team of professionals.

Monitoring of projects by Millcroft’s managers and contracts managers, alongside regular director visits, audits and safety walk rounds, ensures every site is checked and scrutinised by a full team of professionals.

Training and Experience

The role of the supervisor has always been a skilled job, requiring a professional who is both well-qualified and well-suited to the role. As a company that puts health and safety at the heart of everything we do, Millcroft has always looked beyond the standard role requirements when appointing and training foremen as supervisors. Training for Millcroft Supervisors includes at least a five-day Site Management Safety Training Scheme (SMSTS) course, along with in-house mental health training and experience in delivering complex scaffolding projects. All Millcroft foremen are highly qualified in general site management, health and safety and safety leadership, which makes their existing skills a good fit for the Supervisor responsibility. They all have experience of identifying hazards and implementing control measures as part of day-to-day site management.“It’s not just training and experience that are essential to the role of supervisor”Their role involves completing a daily checklist of hazards to mitigate risk, daily risk assessment reviews and pre-start briefings for both the Millcroft team and those working in the area at the beginning of every shift. This includes having an understanding of both Millcroft’s activities, and associated risk factors. The Millcroft Foreman questions all those who attend the daily briefing to verify their understanding and will not allow work to commence until he is confident that all risks have been controlled. Having a Supervisor based on site means that day-to-day changes to hazard and risk can be assessed in the context of site-specific and up-to-date knowledge from the beginning of the working day. Projects do not always run to schedule and supervisory responsibility on-site means that risk can be monitored aligned to actual progress – for the scaffolding and other trades – not to the programme alone, and new safety issues can be included in the daily briefing.

The Right Person for the Job

It’s not just training and experience that are essential to the role of supervisor; a natural aptitude for the job is also important. It’s a responsibility that requires commitment, a can-do attitude and initiative, along with leadership abilities, attention to detail and excellent communication skills. The role involves taking a tough approach to ensuring that everyone behaves safely on site and reports any hazards, but it also involves taking a nurturing approach to gaining trust and supporting the team. Above all, the supervisor role delivers most value in reducing risk and ensuring productivity when it is delivered with a collaborative approach. By combining the duties of Foreman and Supervisor in a single site-based role, health and safety best practice is embedded in day-to-day operations and the team member leading the project on site drives a safety-first culture for all personnel.CISRS seeks anonymous views on Scaffolders CPD training

CISRS has launched a short and anonymous CPD survey to gauge the views from the industry on its somewhat controversial Scaffolders refresher training.

Since CISRS introduced the Scaffolders CPD in July 2017, more than 60% of scaffolders have now completed the mandatory two-day course. Scaffolders CPD was originally introduced following a request from the Health & Safety Executive to incorporate a more thorough card renewal process. A Working Party was set up to discuss and agree proposed content, duration and method of delivery, based upon previous discussions with Access and Scaffolding Industry Training Organisation (ASITO), NASC membership and third parties such as CITB, CSCS and the Unions. CPD caused quite a stir when it was brought in but CISRS say despite the initial reluctance to its introduction, the course has proven very popular, with early feedback collected from delegates upon completion had been overwhelmingly positive, they said. Having now passed the halfway point in the five-year CPD cycle, CISRS are very interested in hearing the views of those that have completed the training and the wider industry. CISRS is seeking anonymous views on the Scaffolders CPD, both in its current form and suggestions for what it may look like for futures programmes. CISRS have said the responses to the survey will assist them when reviewing Scaffolder CPD.Take part in the CISRS CPD survey here.

The CPD survey will remain open until February 28 2021. Dave Mosley, CISRS Scheme Manager, said: “CPD/Refresher training as a scheme requirement caused quite a bit of controversy at the time of its introduction, but most in the sector now accept that as a Safety-critical trade, it makes sense to ensure that Scaffolders are kept up to date with changes within their industry. “We want people to be honest in their responses as such the survey is anonymous. We do, however, want the comments to be constructive. Remarks like “it’s rubbish” will not help us identify areas that require consideration. “If there are specific elements of the programme that someone has concerns with, we want them to let us know and if they can offer solutions to these issues they would be welcomed.”ASTERIX HD Beam now available across all TRAD UK sites

The heavy-duty ASTERIX HD beam is ideal for all applications from large-span temporary roofing to stadium lighting rigs.

TRAD UK, the new brand for the combined TRAD Hire & Sales and TRAD Safety Systems companies, is delighted to announce that the proprietary ASTERIX HD beam is now available for sale and hire from each of its six depots across the UK. At 133cm deep, this high load capacity aluminium alloy beam comes in a range of lengths from 0.55m to 4.0m. With a permissible bending moment of 102.2kNm, and a maximum point load of 47.57kN for all load conditions, along with all chords and posts being manufactured in traditional scaffold tube diameter, the beam is arguably the strongest, scaffold fitting-friendly beam available on the UK market today. The beam also offers consistent nodal spacing, ensuring that lacing and bracing elements are consistent when multiple beams are joined together. Beams are simply joined by utilising a simple 8-hole spigot and quick-release pins. In addition, the ends of the beam are closed, allowing it to be load-bearing along the full length. Importantly for scaffolding contractors, the ASTERIX HD beam is fully compatible with the ALTRIX system and, with ridge pitches of 12°, 18° and 36°, it can be used to form large span temporary roof structures, which previously would have been extremely difficult to achieve. It can also be used within many different types of scaffold structures using standard rather than expensive specialist scaffold fittings. And, like the ALTRIX system’s own beam, the ASTERIX HD beam can be used to form large, fully decked areas using either traditional tube, boards and fittings or systems such as TRAD’s PLETTAC METRIX system. However, with the higher load capabilities of the beam, greater distances between supporting structures can be realised, or higher load classes attained.

Since its launch, the ASTERIX HD beam has been used in a wide variety of construction and refurbishment projects, including the Derby Market Hall Transformation Project, where the beams were used both in the temporary roof structure and the internal support scaffolding.

“The ASTERIX HD beam is an extremely useful product for a range of construction and scaffolding projects,” comments Alan Slater, Head of Technical and Product Support at TRAD UK.

“From large-span bridging sections to temporary buildings, and architectural dig protection structures, these beams are designed to integrate seamlessly with our ALTRIX system and provide straightforward solutions with other standard scaffolding systems.

This makes life as easy as possible for those involved, especially from a manual-handling point of view when compared to alternatives, making it ideal for large or complex construction projects.”

Contractors can buy or hire the ASTERIX HD beam from any of our depots around the UK.

Since its launch, the ASTERIX HD beam has been used in a wide variety of construction and refurbishment projects, including the Derby Market Hall Transformation Project, where the beams were used both in the temporary roof structure and the internal support scaffolding.

“The ASTERIX HD beam is an extremely useful product for a range of construction and scaffolding projects,” comments Alan Slater, Head of Technical and Product Support at TRAD UK.

“From large-span bridging sections to temporary buildings, and architectural dig protection structures, these beams are designed to integrate seamlessly with our ALTRIX system and provide straightforward solutions with other standard scaffolding systems.

This makes life as easy as possible for those involved, especially from a manual-handling point of view when compared to alternatives, making it ideal for large or complex construction projects.”

Contractors can buy or hire the ASTERIX HD beam from any of our depots around the UK. AT-PAC Signs Strategic Global Partnership Deal with Doka

American system scaffolding manufactures AT-PAC have entered into a strategic partnership with Austrian based formwork firm Doka.

The new deal will allow Doka to offer AT-PAC’s Ringlock Scaffold System and Hi-Vis® Scaffold Management Technology under its portfolio of products, globally.

Doka – a world leader in developing, manufacturing and distributing formwork solutions will now offer scaffolding solutions.

AT-PAC said the partnership marks a major milestone in its 25-year history and demonstrates the internationally recognised quality of its products and ability to service major customers on a global scale.

Jeff Davis – CEO of AT-PAC said: “With Doka we have a strong partner in the construction industry. This strategic partnership means that Doka’s customers can benefit above all from the fact that they get everything from a single source”.

Doka CEO Harald Ziebula added: “With this strategic partnership we offer much more than just scaffolding. We are now offering – as we have been doing in the formwork sector for decades – well thought-out scaffolding solutions and services to our customers.”

CITB agrees sale of National Construction College Midlands

The CITB has agreed to sell its Midlands National Construction College (NCC) to Walsall College on 30 November.

The sale includes the land, buildings and business based at King’s Norton in Birmingham. 17 CITB staff members are also being transferred over as employees of Walsall College. An experienced construction skills provider, Walsall College will look to further develop a comprehensive offer for apprentices and work-based leaners that takes them from basic to advanced skills training in sector specialisms including scaffolding and roofing. The sale of the college by CITB is part of its Vision 2020 programme. Reforms include handing over direct training to alternative providers who can offer a service at least as good as that which is currently in place. This allows CITB to focus on delivering improved skills outcomes for all construction employers across Great Britain. Braden Connolly, CITB Director of Products and Services, said: “Walsall College is an excellent Further Education provider with a strong track record and links to employers all over the region. This landmark agreement will secure a bright future for high-quality construction training provision for the industry in the Midlands, with commitments to maintain and develop existing training and with no redundancies from the sale. “It also marks the first of our four National Construction College facilities across the country to be sold to an alternative training provider, as part of our programme to reform CITB to better serve the sector for the future.” Jatinder Sharma, Walsall College’s Principal and Chief Executive, said: “This acquisition takes the college in a new direction for which we are ideally situated. It utilises our expertise in key areas, while enabling us to increase the level and breadth of our provision. “Construction and infrastructure are priority areas for economic recovery in the West Midlands. The emphasis really must be on how we widen our support for local employers and their workforces; ensuring they access the right skills to accelerate the pace of these new builds and redevelopments. “We look forward to getting started.” The National Construction Colleges remain open for business and are taking bookings both now and into 2021.Scaffmag Issue 11 Launches

The latest issue of the Scaffmag magazine has just been published online.

Welcome to the latest issue of Scaffmag magazine which is jam-packed with interesting stories from across the industry. Since our last issue back in August, our sector and the wider construction industry seems to now be on the right path for a hopeful recovery. However, just as the country was getting used to some kind of normality, little did we realise another lockdown would be placed upon us all.

But while economic uncertainty still hangs in the balance, fortunately for us the government continues to support construction as a key industry along with those businesses that supply it, ultimately giving us the green light to continue to operate and ‘keep calm and carry on’, as long as we stick to the guidelines.

And encouragingly, as I write this, the very welcome news of a breakthrough in the race to find a Covid vaccine has shown the world there really is light at the end of the tunnel.

In This Issue

In this issue we have looked to have a special focus on careers, equality and inclusion within the scaffolding industry and as our sector begins to bounce back, we are asking ourselves, could we actually bounce back better?

On page 25, Des Moore discusses ways of encouraging new people to join the industry by providing them with a career, not just a job. In his article Des believes, as an industry, we need to widen our horizons if we are to find the workforce we need to fulfil our project opportunities.

Meanwhile on page 40, our man Richard Trenchard speaks with women in construction and within the scaffolding sector on how we can inspire and encourage other women to join the industry. “I would have to say although it has improved over the 15-plus years that I have worked in the industry, it still has a long way to go,” says Scaffolding Surveying Manager, Tanya Hamilton.

Elsewhere, on page 44, Helen Gowor explains how valuing different skills to encourage diversity not only benefits businesses but helps increase profitability.

And finally, with the nights drawing in and the colder weather on the way, thoughts across the scaffolding sector are turning to winter and what it means for on-site working. On page 50, our friends at Leach’s share their top tips to protect scaffolders this winter.

Happy reading, and stay safe!

Daniel Norton – Editor

TechniSpan suspended platform launches in the Nordics

An innovative suspended platform has been introduced to the Nordic market by temporary access solutions provider HAKI.

The flexible TechniSpan system, which was originally developed by HAKI’s recent acquisition Span Access Solutions, improves the efficiency and safety of underdeck, bridge, and jetty works in the important offshore, energy, and infrastructure industries.

With fewer contact points than traditional scaffolding, the unique traversing system can be easily and quickly erected, lifted, and lowered to cover large working areas, leading to an overall reduction in project time schedule and labour costs for Nordic customers. Technispan system also contributes itself well to complex environments by overcoming challenging difficulties in permanent structures, where conventional solutions often fall short due to limited flexibility.

The suspended platform system can, with great benefits, be integrated with the HAKI Universal scaffolding system to offer new solutions and methods for accessing project requirements in dynamic situations. By combining both HAKI and Span Access’s products and support services, customers can expect a complete service from design to supply, including expert technical advice throughout the project.

Commenting on the entry to Nordic market, HAKI CTO and Span Access MD, Ross Turner said: “By introducing this new innovative access and safe workplace solution to the Nordic region, HAKI and Span Access, will transform the market.

“All the experience and expertise we have established with TechniSpan in the UK market will enable us to deliver highly successful projects in the Nordics, in scenarios where traditional scaffolding would fall-short.”

TechniSpan and the Span Access brand have already proven their capabilities in the UK market, being commissioned for high-profile projects on Scotland’s iconic Forth Road and Rail Bridges and numerous offshore oil and gas projects.

TechniSpan in action on the Forth Bridge

During routine inspections of the Forth Road Bridge in 2015, a crack in the pivot of one of the truss end links was discovered. The changeout of the affected steelwork initially took 18 months to complete; largely slowed down by the traditional scaffolding having to be continually modified to react to the changing work scope and with the scaffolders impeded with a lack of suitable steelwork for their connections into the structure.

Subsequently in 2017, Transport Scotland decided to change the remaining seven end links as a precaution. Due to the disappointing results using conventional access methods, Span Access was contracted to design, engineer, and install a bespoke access system for the later works.

A completely unique hybrid solution using the TechniSpan suspended access platform was specified, which was easily capable of spanning the 10m between structural pick-ups while retaining the strength required to support a five-lift scaffold in its entirety. This in turn was mated with a compatible HAKI Stair Tower, constructed from the platform deck level; giving the contractors five working lifts to access all areas of the scaffold.

Several scenario drawings and checks were completed by the in-house design team, prior to installation, to allow the platform to be opened-up and allow the lifting in of steelwork from river level. A host of hop-ups and variations on the five-lift scaffold were also all designed and checked in advance to give the project the flexibility it needed to succeed.

Additional engineering support throughout the project allowed the client to react to unforeseen circumstances and the swift removal of the system allowed normal bridge operations to resume earlier than planned.

Together, Span Access and the TechniSpan system, helped achieve an 80% reduction in installation time over traditional scaffolding. This led to successful delivery of the project, along with the additional pre-mobilisation engineering works which allowed for most modifications to be completed without works being halted.

Learn more at https://bit.ly/2Ks6mcr

Recruitment drive re-launched for new construction assessors

A project to recruit and train 100 quality assessors for the construction industry in Scotland – which was put on hold due to the Covid-19 pandemic – has been re-launched.

The two-year project, driven by CITB and ESP, in partnership with 24 Scottish colleges, government agencies and private training providers, was originally unveiled back in early March this year.

The re-launch of the recruitment campaign is more good news for the construction industry – which has like many other industries – struggled during the lockdown.

Recruitment of the new assessors will enable more efficient delivery of onsite assessments for apprenticeships in Scotland and help the promising economic recovery that is being made in the construction industry as it emerges from months of inaction.

Recent initiatives such as the UK Government’s Kickstart programme – where employers can offer youngsters aged 16-24 who are claiming Universal Credit a six-month work placement – as well as Skills Development Scotland’s enhancement to their ‘Adopt an Apprentice’ scheme, which has seen the funding grant raised to £5,000, have been welcomed positively by building firms across the country.

During this time colleges across Scotland have been offering more full-time one year construction courses, to enhance the pipeline of work ready MA’s for employers.

The College Assessors role offers a secure and rewarding opportunity with a competitive salary, generous holiday entitlement and benefits package. They are responsible for carrying out a wide range of assessment and verification duties and ensuring apprentices have the skills and knowledge to pass their course outcomes. Additionally they play a key role in ensuring qualifications are delivered to a high standard through compliance with both internal and external awarding body policies, procedures, processes and standards.

The project forms a major part of the CITB’s new strategic road map launched in September (2020), which will focus on a smaller number of priorities to help modernise construction and increase productivity, collaborating with industry, governments and Further Education (FE).

Assessors will be recruited across a range of curriculum areas, including Carpentry & Joinery, Brickwork, Painting and Decorating, Roof Slate and Tiling, Wall and Floor Tiling, Stone Masonry, Wood Machining and Plastering.

Colleges and training providers will continue to recruit individually, while the assessor vacancies will be promoted via a national campaign. The campaign will primarily target individuals working in the construction sector, who may be seeking a full-time or part-time career change with the opportunity to help support and deliver the industry’s future workforce.

As part of the project, West College Scotland (WCS) has been selected to deliver bespoke training to new assessors, which will complement essential qualifications being undertaken through employers such as the L&D9DI and L&D11 – SQA qualifications for assessors and verifiers. WCS are also developing an e-portfolio which will be available free to all training providers as part of this project. Finally, Forth Valley College have also been involved providing Communications, PR and Marketing support for the re-launch.

Jim Brown, Director of ESP, said: “It has been a challenging few months for every industry across Scotland, but we’re excited to be relaunching this campaign at this time. Ensuring we have the Construction Assessors in place across Scotland will support young people into the construction sector and hence underpin the economic resurgence of the Construction industry and secure its future. It will also provide real opportunities for those with experience in the sector who are seeking a new career.

“Becoming an assessor can be a secure and rewarding career choice and the opportunity to shape the next generation of talent. It is a key role in the success of the construction sector, helping new entrants to gain their qualifications and become highly skilled in their trade.

“We originally began the recruitment campaign during Scottish Apprenticeship Week 2020 as it seemed like the perfect time to launch the project. The importance and value of Modern Apprenticeships are recognised throughout the country, and they wouldn’t be achievable without the help and support of the Assessor role.

“This is a fantastic opportunity for experienced industry professionals to use their skills and knowledge in a new capacity and we would encourage them to find out more about this fantastic job opportunity.”

Ian Hughes, CITB Partnerships Director Scotland, said: “Our evidence-based approach to funding will help the construction industry deliver tailored training and assessment to fulfil Scotland’s skills needs.

“The Scottish Assessors project is a great example of how our work in partnership with training delivery organisations ensures that employers have the right people, with the right skills, in the right place. With an average annual growth rate of 1.4% forecast across 2021-2025 for Scotland, our Construction Skills Network (CSN) report highlights the importance of investing in skills.”

Gordon Nelson, Scotland Director at the Federation of Master Builders (FMB) is quick to point many small building firms are finding themselves very busy right now as homeowners use the lockdown restrictions as an opportunity to build extensions or make renovations and refurbishments to their properties. This could lead to them hiring more apprentices.

He said: “Many of our Master Builder members take great pride in recruiting and training construction apprentices.

“Our members have high standards, which is why it is important that the new assessors have sufficient skills and knowledge to ensure apprenticeship qualifications are delivered to high standards too.

“Prior to impact of Covid-19, some members also expressed an interest in becoming assessors themselves. To ensure Scotland’s construction industry has a bright future, we will need a healthy pipeline of skilled and qualified apprentices to become the Master Builders of tomorrow.”

Mark Stevenson, Apprentice Manager for Taylor Wimpey West Scotland, said: “Future-proofing our industry and attracting the right talent who are ready to learn the skills that we need to deliver high quality new homes for our customers is a real focal point for our business. Having access to a CTB appointed work-place assessor will ensure a consistent approach, which will benefit apprentices and companies by improving the overall quality of learning and individual achievement. This can only be good for our industry, especially in these unprecedented times.”