The NASC has just unveiled the cost of its eagerly-anticipated eGuide scaffolding design software, TG20:21.

The new product, which updates and expands on TG20:13, the NASC’s innovative, user-friendly and widely-adopted software, will be available from March 2021 on an annual subscription basis.

Details were revealed by NASC President Lynn way at the NASC’s annual general meeting earlier today that was held online. TG20:21 will cost NASC members £75 per eGuide subscription per year and non-members £300 per eGuide subscription per year.

Users will be able to access TG20:21 – and the associated and updated Operational and Design guides – via a link from the NASC website using a unique serial number and login credentials rather than via a file download or CD.

To ensure the transition for existing users from TG20:13 to TG20:21 is as fair as possible, there will be a short period of free use of the new software.

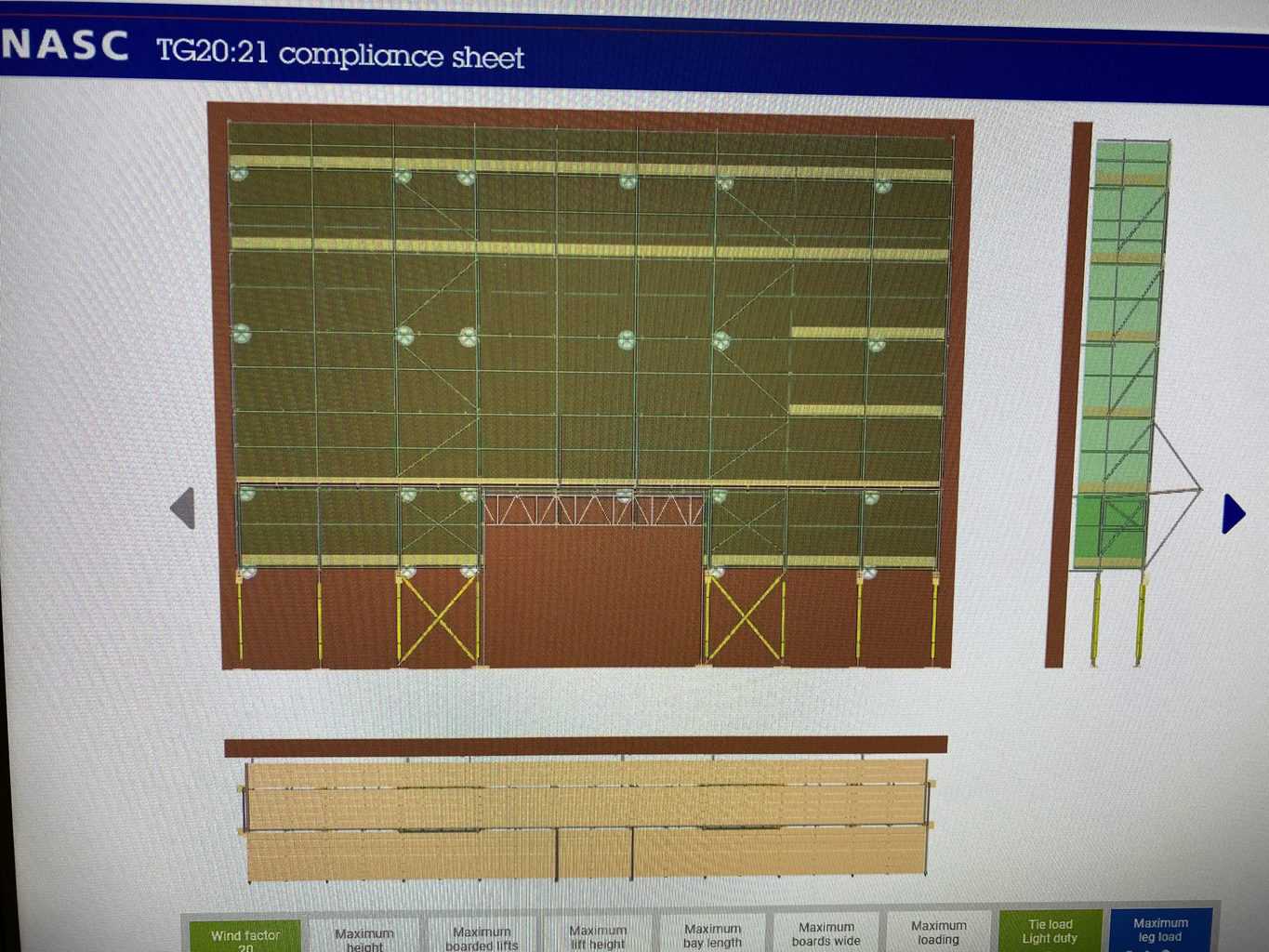

TG20:21 features a number of changes from the existing TG20:13 software to make the process of producing a compliant scaffolding design even simpler and additions to make the software even more useful.

These additions include exterior birdcages, tube and fitting mobile towers, tube and fitting loading bays without beams and tied independent scaffolds with three inside boards.

The TG20 compliance sheet will now be double-sided with the illustration and principal compliance criteria on the front side and the detailed compliance criteria listed on the reverse in landscape format.

Lynn Way said: “TG20:13 was a huge step forward for the scaffolding industry, revolutionising the way scaffolding contractors produce day-to-day scaffolding designs and ensure their scaffolding projects are safe and compliant.

“TG20:21 is another step forward. Not only has the scope of TG20 been expanded but it’s also been further simplified – making it easier than ever to use and covering a broader range of scaffold designs.

“On top of this, the TG20:21 suite will be accessible via a dedicated digital portal, again, making it much more user friendly. I’d like to thank all the NASC Committees that played a part in working on TG20:21 as well as our long-standing software developers CADS for their efforts in bringing it to life.

“Of course, the work doesn’t stop here and we’ll continue to innovate and improve in any way we can to make the scaffolding industry safer for all.”