TRAD Scaffolding celebrates apprentice award shortlist

TRAD Scaffolding Co, part of the TRAD Group, has announced that one of its apprentices, Stephanie Betts, has been shortlisted for the ‘Apprentice of the Year’ award, part of the Construction News 2020 awards.

Stephanie, who is halfway through the five-year apprentice programme and is due to complete her apprenticeship in 2022, has been shortlisted for her outstanding attitude to her work and for achieving great results. Scaffmag asked Stephanie a bit about her time with TRAD and her thoughts on the award and on life as a woman in the construction industry.What made you apply for the apprenticeship scheme at TRAD?

“Coming from a financial background, I wanted something completely different from my previous roles as well as hopefully being taken out of my comfort zone. The trainee management scheme looked exciting, and TRAD is an ever-growing company with nearly 50 years of history, which is something I couldn’t wait to be a part of.”What has surprised you or been unexpected about the scheme?

“The Trainee Management apprenticeship has several modules and the first one I experienced was out on-site working alongside the TRAD team and learning the basics of contract scaffolding, I thought going into a male-dominated role would be incredibly intimidating, but everyone has been so friendly and supportive and it was a real help to see how scaffolding works in a live environment.”Have you found TRAD to be supportive of your training and career?

“TRAD has been very supportive of my training. All of the modules I’ve carried out so far including estimating, surveying, management and supervision have interlinked smoothly. My colleagues in each module have many years of experience and it’s been interesting to see how our customers receive a service from concept design and advice, safe erection and dismantle and meeting programme needs all the way through to final account.”What’s great about being shortlisted for this award?

“I feel excited to have been nominated for this award because being female in a traditionally male-dominated environment on site is quite a challenge. Even though TRAD has a strong female representation within the company, most sites do not – and to have been recognised for my effort and hard work feels like a massive achievement.”It sounds like it’s been a challenge – what has been the best bit of your training so far?

“I really enjoyed my time on site: my previous roles have been office based so I have never experienced working on a construction project. It was really interesting to have a change of scenery from the office and I was completely taken out of my comfort zone, which excites me. Having walked past many construction sites in my previous employment without giving them a second thought, now I’m actively looking at what’s going on inside!”What do you think about opportunities for women in the construction industry?

“I feel that women in construction are becoming more recognised – that’s certainly what I’ve found within the TRAD Group and it’s a great industry for any female to get involved with. There are so many different opportunities and it’s honestly not as scary as we first think!” The winners of the Construction News awards will be announced on November 17th at a virtual ceremony.North American firm buys Turner Access OCTO scaffolding system

Turner Access has pulled out of the system scaffolding market after selling its system scaffolding production and sales arm.

The Glasgow based firm will now focus on its rapidly expanding contract scaffolding business activities in the construction, infrastructure and other industry sectors. The company has said today that Sunshine Enterprises has successfully purchased the production and sales arm of OCTO® System Scaffolding from the scaffolding supplier. OCTO will now be traded via StepUp Scaffolding UK Ltd which is owned by North American business Sunshine Enterprises. Sunshine Enterprises is one of North America’s largest scaffolding importing and manufacturing brands. This new deal puts the company further into the UK and European markets, boosting the existing scaffold and access sales operation of StepUp Scaffolding UK. StepUp Scaffolding UK (Ltd) will continue to serve its existing UK and European customer base, via a newly formed brand, Sunshine Enterprises Group Europe – crucially now with the addition of the highly regarded OCTO® System Scaffolding range to its expanding portfolio. New Sunshine Enterprises Group Europe Managing Director, Knud Højland Pedersen said: “This deal is fantastic news for the UK scaffolding sector – allowing existing StepUp Scaffolding UK (Ltd) and new British and European customers to slickly and efficiently benefit from the safety and productivity-boosting gains of the fantastic OCTO® System Scaffolding, at a time where safety and speed in scaffolding has never been more critical.

Having the scale, speed and quality of a brand like Sunshine Enterprises behind the StepUp UK business is going to put OCTO® System Scaffolding on the map here in the UK and beyond.”

Turner Access new Managing Director, Simon Russell said: “This is great news for Turner Access as a brand and our Scottish and UK-wide construction customer base. The shift of emphasis here from production of scaffolding to contract activity and the huge investment and growth this deal will help to support will help us in our vision to be the leading scaffold contractor in Scotland, offering clients a first class scaffolding service in accordance with our #WorkSafeHomeSafe culture – ideally suited to the current situation.”

StepUp Scaffolding UK (Ltd) are now taking orders for the entire OCTO® System Scaffolding product range and Turner Access are available to quote for contract scaffolding.

New Sunshine Enterprises Group Europe Managing Director, Knud Højland Pedersen said: “This deal is fantastic news for the UK scaffolding sector – allowing existing StepUp Scaffolding UK (Ltd) and new British and European customers to slickly and efficiently benefit from the safety and productivity-boosting gains of the fantastic OCTO® System Scaffolding, at a time where safety and speed in scaffolding has never been more critical.

Having the scale, speed and quality of a brand like Sunshine Enterprises behind the StepUp UK business is going to put OCTO® System Scaffolding on the map here in the UK and beyond.”

Turner Access new Managing Director, Simon Russell said: “This is great news for Turner Access as a brand and our Scottish and UK-wide construction customer base. The shift of emphasis here from production of scaffolding to contract activity and the huge investment and growth this deal will help to support will help us in our vision to be the leading scaffold contractor in Scotland, offering clients a first class scaffolding service in accordance with our #WorkSafeHomeSafe culture – ideally suited to the current situation.”

StepUp Scaffolding UK (Ltd) are now taking orders for the entire OCTO® System Scaffolding product range and Turner Access are available to quote for contract scaffolding. Scaffolding and mansory firm expands into Leeds

Scaffolding and brickwork business Lee Marley Brickwork Ltd (LMB) has opened a Leeds Office which forms part of a National Expansion Plan.

The firm says the company has chosen Leeds as its base in the North of England because of its good transport links and highly skilled labour pool.

With offices already in London, Reading and Glasgow, Leeds is the next step in their national expansion plan.

The multi-million-pound nationwide enterprise was formed in 1997 by founder Lee Marley who was just 24-years-old at the time. His business is now a major integrated brickwork, scaffolding and stone subcontractor, and it turned over £47.1m in 2019. Read our magazine interview with Lee Marley from issue 10Its new regional office based in Thorpe Park, Leeds is set to be head by Mike Hampton who has been appointed Commercial Director.

Mike is a seasoned industry executive who brings 20 years of masonry experience in the north and midlands to the business.

He added: “The opportunity to join one of the leading masonry companies in the UK was too good an opportunity to miss. There is huge potential in the north as masonry packages grow bigger and bigger and it shows great confidence in the region that LMB wants to become part of the Northern Power House story”

LMB Director Dan Clarkson said: “Mike is a great addition to our team. Many of our clients have been asking us to work in the region for some time but we have been waiting to recruit individuals that share our drive, commitment to quality and customer focus”

LMB Managing Director Lee Marley said: “We have worked all over the country on major projects but it has always been an ambition of mine to have a permanent base in the region to create a bridge between our work in Scotland and the South and offer a comprehensive national masonry solution to our customers”

Lee Marley Brickwork’s team includes operational and commercial management and will be focussing on large scale schemes that have become the company’s hallmark in Southern England and Scotland.

Future business plans include working in partnership with local colleges and universities in the North of England to further develop LMB’s apprenticeship and graduate programmes.

CITB calls for crackdown on fraud in construction

Organised crime is cashing in on pent-up demand for construction testing, and the CITB needs your help to stop it.

Criminals in London, the Midlands and in the North West are charging candidates more than £1,000 for assisted one-day Site Safety Plus (SSP) courses and the CITB Health, safety and environment (HS&E) test – the true cost of the HS&E test is just £21! The CITB say that training providers in the capital, as well as areas in and around major British cities, are being approached by individual facilitators allegedly offering to bring in large numbers of candidates and asking to use the provider’s facilities and registrations. Some of these facilitators offer large amounts of cash as an incentive, but after the courses are run the cash is not forthcoming and the centre finds their standards may have been compromised. CITB is currently conducting investigations and involving law enforcement agencies including the National Crime Agency, police, Home Office Immigration Enforcement and the Gangmasters and Labour Abuse Authority as appropriate. Quality assurance audits are being provided to training centres, and CITB’s fraud team also identifies and targets offenders, including through unannounced audit visits. Ian Sidney, CITB Fraud Manager, said: “The intelligence we are receiving is that the fraudsters are trying hard to capitalise in on a surge in demand caused by the lockdown. We know that organised crime infiltrates the testing process to get unskilled, illegal or trafficked people genuine qualifications so they can work in conditions of modern slavery on construction sites. “This generates vast sums of money, some of which is known to help to finance terrorism and other organised criminality. You can help put a stop to it by getting in touch.” If you are approached by unknown facilitators please let CITB know and help prevent fraud at [email protected]Wood extends training contract with 3t Energy Group

Global engineering and consultancy company, Wood, has renewed its training management service (TMS) contract with 3t Energy Group for a further three years, until 2023.

3t Energy Group, which includes AIS Training, Survivex, Drilling Systems, and Transform, has been contracted to deliver support for Wood’s onshore and site-based training and competency requirements in the UK since 2017. In that time, 3t has focused on digitising and streamlining to drive efficiency, as well as delivering thousands of world-class, industry-accredited technical and safety-critical skills courses and assessments. As part of the extended contract, AIS Training and Survivex will continue to deliver training courses with Transform’s award-winning, cloud-based, training and competency systems managing the training process. Transform will also work closely with Wood to develop more ground-breaking, technology-led solutions including mobile phone apps to boost knowledge retention, self-service options for delegates who want to arrange their own training, and ‘blended’ learning solutions focussed on integrating technology and digital media with traditional classroom methods to provide customised training. Gavin Taylor, Vice President of Global Sales & Strategy at 3t Energy Group, said: “We are delighted Wood has extended our contract and are very much looking forward to evolving and enhancing our services together. Our partnership with Wood has been the catalyst for some of the most ground-breaking technology developments in the training sector such as our cloud-based, ‘Transform’ training and competency systems, which enable companies to seamlessly track every detail of workforce and asset compliance from one central platform. “Together with Wood, we want to continue developing innovative, market-leading, digital solutions for learning and development and we are excited about entering this next phase of our relationship.”Industry to carry on through latest national lockdown

Construction sites in England are set to stay open and fully operational during the latest lockdown that starts on Thursday.

Prime Minister Boris Johnson addressed the nation on Saturday evening to announce a four?week lockdown in England from this Thursday 5 November until Wednesday 2 December. The new restrictions include requiring people to stay at home except for specific purposes, not mixing with other households, and the closing of certain businesses and venues. The PM stated that Construction and manufacturing should stay open across all four nations. Build UK has said they advise sites to review their social distancing measures and remind the workforce of the importance of complying with the Site Operating Procedures ? Version 6 whilst on-site, as well as the new restrictions off-site to protect their family and colleagues.Working on Houses

Scaffolding firms and other tradespeople can also continue to work on and in people’s homes as long as both the worker and household members have no symptoms of coronavirus. Build UK’s Work Safe Safe Work Guide can be used to reassure householders. Hotels have also been told to remain open to provide accommodation for workers.Furlough Scheme Extended

The PM also announced that the Coronavirus Job Retention Scheme is being extended for one month, with employees receiving 80% of their current salary for hours not worked, up to a maximum of £2,500. Under the extended scheme, employers will only have to pay National Insurance and pension contributions, with the Government paying the full 80% of wages, and details of how to claim will be available shortly. The Job Support Scheme, which was due to start on 1 November, has been postponed until the Job Retention Scheme ends.Top trainer launches Layher Scaffolding Apprenticeship Scheme

A leading scaffolding training firm has announced the introduction of a Layher scaffolding apprenticeship scheme.

SIMIAN the UK’s largest privately-owned scaffolding training provider has launched the new apprenticeship scheme following the increased exponential UK growth of the use of the Layher Allround system.

The Layher Allround system is widely regarded as one of the world’s premier modular scaffolding systems. Over the last few years, many UK firms have adopted the system converting from the traditional tube and fitting scaffolding.

Fully supported by Layher UK, SIMIAN say it’s apprenticeship scheme will start in early 2021 with candidates progressing to become qualified Layher Scaffolders in the early part of 2023.

In addition to the benefit of gaining a more skilled workforce, employers taking on a Layher apprentice could also benefit to the tune of as much as £2k per apprentice if signed up by 31 January 2021, as per the Government’s current apprentice employer’s incentive.

There is no upper age limit for apprentices, but employers of those aged over 25 will receive £1.5k per apprentice.

To launch the initiative, SIMIAN is hosting 2 apprentice assessment days, one in the North, at it’s Warrington Centre and one in the South, at their Waltham Forest centre.

- Warrington – 30 November 2020

- Waltham Forest – 03 December 2020

The assessment days will be used to provide information on how the scheme works on what the various parties can expect from one another, and to assess the suitability of candidates to enter the apprenticeship programme and will include an assessment of their ability in English and Maths

Speaking of the initiative, Simon Hughes, MD at Simian said: “We’re really pleased that our proposed Layher apprenticeship programme is starting to gain traction and it’s another very exciting addition to the scaffolding training courses that we deliver.

In terms of Layher, there will now be three routes to becoming qualified, and the apprenticeship programme will add to the existing traditional part one and two routes and the System Scaffold Product Training Scheme (SSPTS) route.

It’s vital that we get the support of Layher users for this initiative, so I’d like to personally ask Layher-using employers and would-be apprentices to consider this route. We’re very hopeful that the Government apprentice incentive scheme grant of up to *£2k per employee, in addition to any other grants that are payable, will encourage sign ups. This means that in addition to the financial benefit, employers will also receive the benefit of an upskilled workforce.”

Hadley Scaffolding expands into waste management

Access specialists Hadley Scaffolding have diversified after launching a commercial waste management venture.

Established in 1997, Hadley operates from its headquarters in Rochester and has depots in Avonmouth, Hastings and Salford. The firm has always played a particularly prominent role within the rail and road infrastructure sectors.

It’s recent rebranding as Hadley Group follows the decision to diversify into the commercial waste management sector.

Hadley’s Managing Director Carl Byford explained: “It’s just a sideline at this stage, and we’ve only assigned the single tipper-grab to the new venture so far. But we’re aiming to target a lot of the big builders to which we already supply scaffolding services, and are confident it represents a genuine opportunity to grow the business.”

The new venture comes after the firm commissioned its first tipper-grab, a 32-tonne Mercedes-Benz Arocs built for the manufacturer’s Work Ready programme.

Although the Kent-based operator runs a number of other Mercedes-Benz trucks, the latest are its first new-generation models. Innovative technology includes the camera-based MirrorCam system, which replaces conventional mirrors and represents a major safety breakthrough.

“We’ve put two experienced drivers on these new trucks and they’ve adapted to MirrorCam very quickly,” said Mr Byford. “Both have told me they prefer the cameras to mirrors, because they can see so much more.”

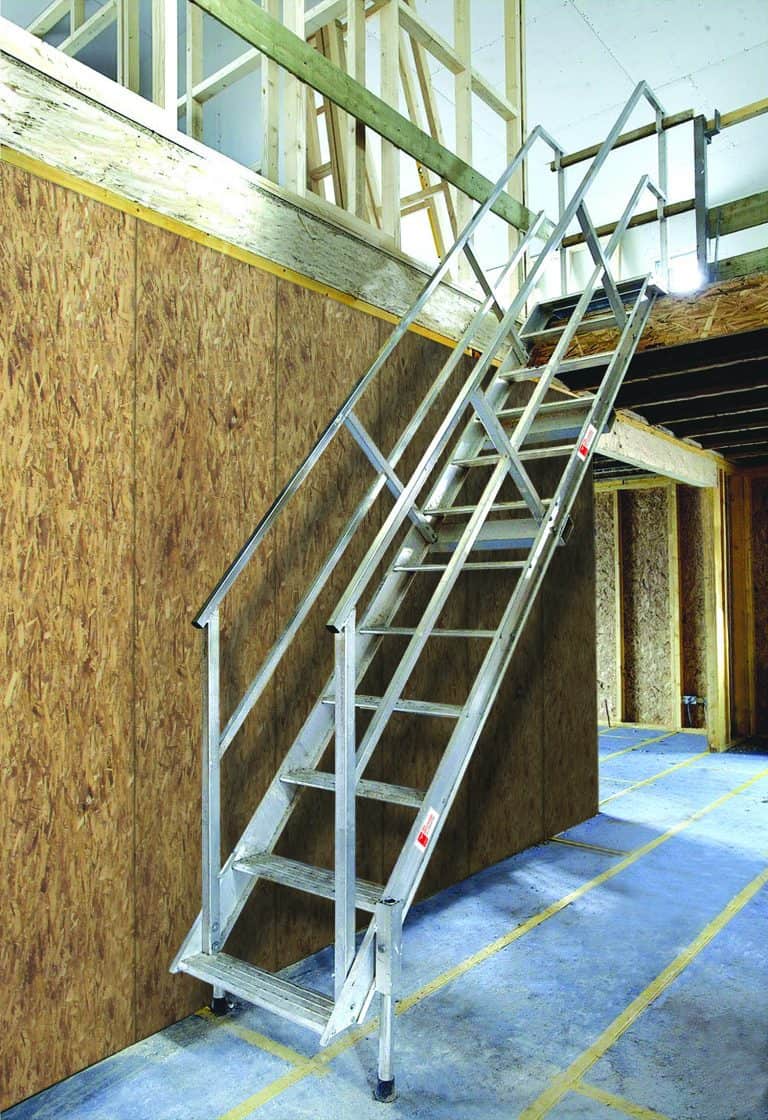

TRAD Temporary Stair Unit Improves Safety For Housebuilding Constructors

TRAD UK, the new brand for the combined TRAD Hire & Sales and TRAD Safety Systems companies, can supply contractors with a safe, useful internal staircase that’s ideal for housebuilding sites, where the staircase is often the final element to go into the building.

Used by customers in projects where access to the upper floors of the building is not available from an external scaffold, the stair is a single complete unit that’s light enough to be easily moved around the building and secure enough to keep workers safe whilst using it. Adjustable feet mean that the stairs are height-adjustable from 2.70m to 2.95m, allowing access to most modern floor heights and, with a weight limit of up to 150kg, the stairs have been tested to all relevant British and European standards, so can be used with confidence.

Developed with modern housebuilding techniques in mind, the TRAD Temporary Stair Unit is already in use across a range of housing development projects and offers scaffolding contractors the opportunity to provide additional services and equipment to clients – saving time and money in the process.

Non-slip internal stair improves efficiency and reduces on-site accidents

- Load capacity up to 150kg

- Non-slip surface assists grip

- Easily moved around construction site, utilising the integral forklift pockets

- Exceeds HSE Working at Height regulation requirements

- Easy installation by two operatives.

- 600mm tread width

- Range of height adjustment

“The TRAD Temporary Stair Unit allows scaffolding contractors to provide safe working environments inside buildings as well as outside,” says Derrick Quinn, TRAD’s Technical and Product Support Manager.

“This helps them to provide a wider range of services to their customers – whether they hire or buy. The stair is a single unit, with height adjustment available and an optional extended landing platform that allows the stair to achieve a greater span over voids in projects like town house construction.”