The National Access and Scaffolding Confederation (NASC) has received reports of their full contracting members being allegedly scammed at great financial cost by a company calling themselves ‘BR Network.’

Using the name of ‘Project Hub’ on their correspondence, the firm has been offering a service on behalf of so-called main contractors aimed at sourcing reputable scaffolding companies for potential contracts.

A Believable Approach

Their approach has been described as professional and convincing using what on the face of things is a good storyline. The bad news is however, once the organisation has received their sizeable subscription, any so-called leads rarely materialise if at all.

Lack Of Leads

Robin James, NASC Managing Director explained: “One member reported they had received only one reasonable lead in the first three months. Upon complaining to BR Network that they were not supplying what had been discussed, they were then offered an enhanced service at an additional cost to put the complaint right and provide commercial leads for sub-contract scaffolding works.

“The member was then charged an extra cost to try and obtain what they thought they were getting in the first place, as BR Network provided the company with a further contract as a way of dealing with the complaint. When this second contract (and payment) also did not deliver what was originally offered, the NASC member company had no option but to terminate the contract.

“However, terminating the contract was not as straightforward as expected. Having given notice by recorded delivery, the stance of BR Network was to cancel the original contract, but not all the contracts.

“At a later point a new invoice for immediate payment was issued by BR Network for the enhanced section of the contract. It transpired this section of the contract had remained effective and had not been cancelled. The cycle of payment continued to be requested and enforced, with the same absence of leads for work being offered, hence another costly termination fee was demanded.”

Trustpilot Advice

Web-based Trustpilot has received a large number of

complaints about the way this company operates. They say: “To our knowledge, this company collects reviews by asking its customers to share their experiences on Trustpilot. This company has claimed its Trustpilot profile, but to our knowledge, doesn’t actively invite its customers to write reviews on Trustpilot.”

At Risk

It’s clear falling for such schemes also affects both large and small enterprises, all in the constant search for ongoing work. But this can sometimes come at huge cost. It also seems BR Network keep approaching various construction-based firms. This only results in both a time consuming and expensive cycle when terminating the contract. Robin James adds this piece of vital advice: “NASC members are urged to be wary when dealing with companies such as BR Network and Project Hub. It’s best to do plenty of research and take the best advice.”

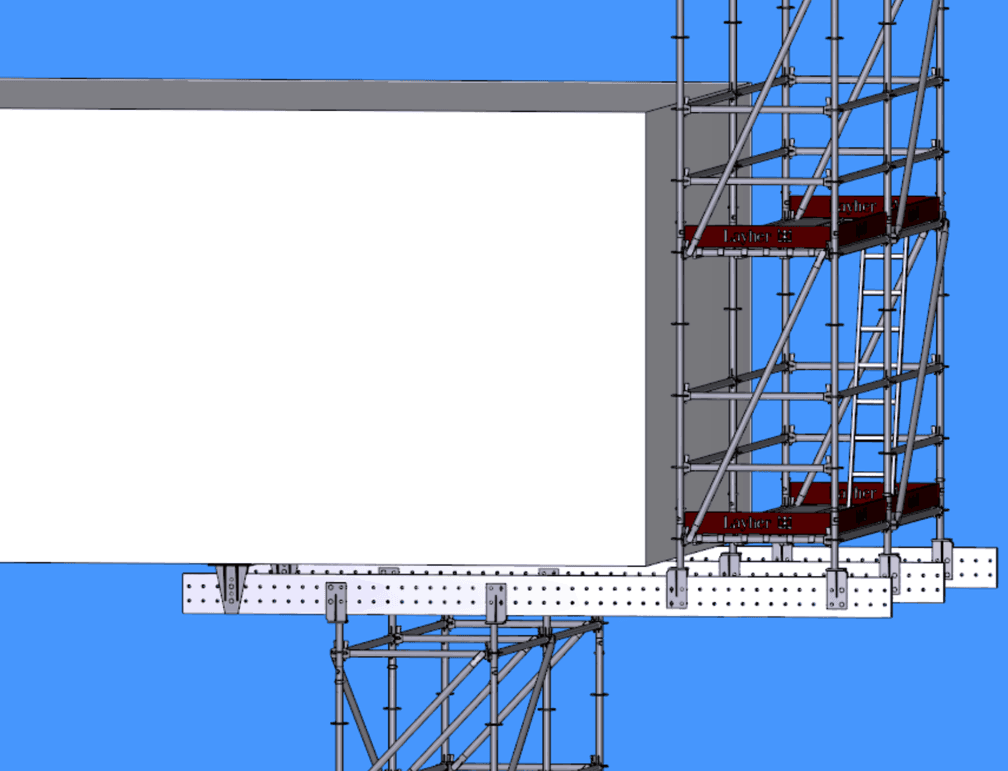

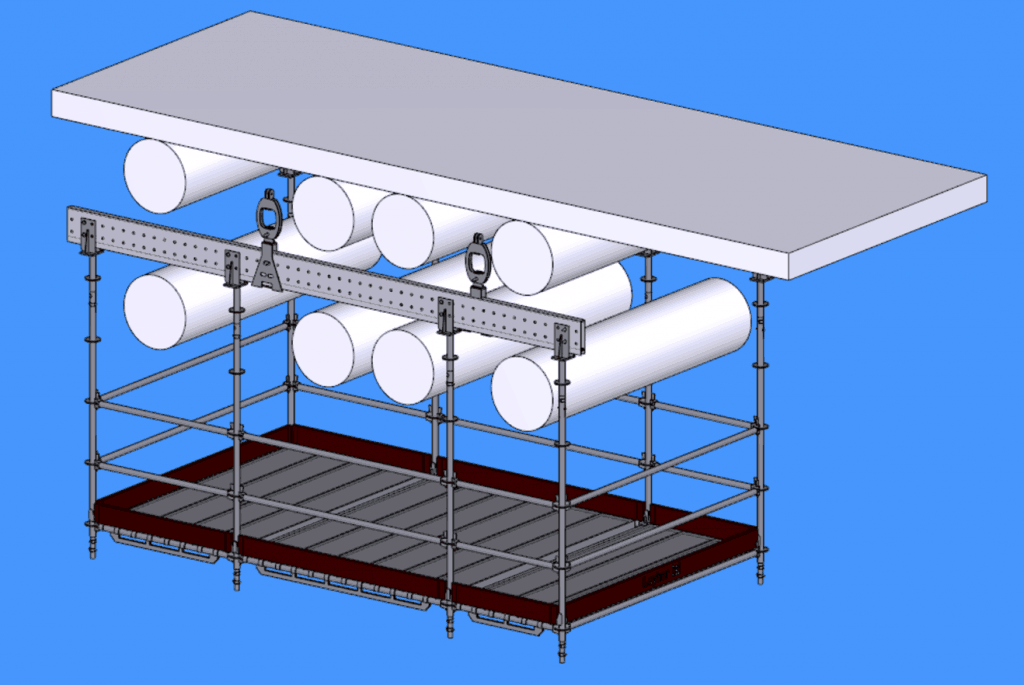

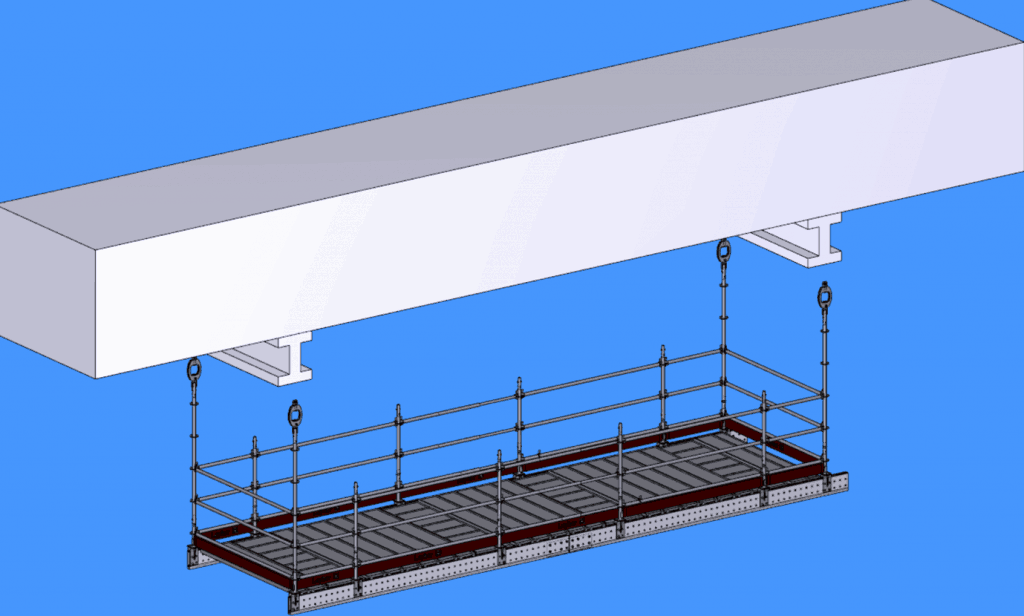

With the Forth (Rail) Bridge opening in 1890, the Forth Road Bridge in 1964 and the new Queensferry Crossing opening in 2017 our bespoke platforms are currently supporting the infrastructure from three centuries of crossings over the Firth of Forth.

Span Access Chairman, Kenny Wiggins said:

“Span has had an exciting year as we have supported these key projects, working on all three of these iconic bridges simultaneously shows our innovative capabilities with alternative access. Each of the bridges required a different solution, developed and installed exclusively to meet the needs of the client.”

Span Access has also received Expert Help assistance from Business Gateway Fife. Their adviser, Lynne Baillie, commented:

“Span has shown that it has ambitious plans for the future of its alternative access solutions business. Their work in a diverse range of sectors, including the recently announced Innovate UK backed offshore wind project proves the worth of their innovative approach to solutions for major infrastructure projects.”

Span Access has experienced significant growth in each of the last two years with a focus on Infrastructure, Oil & Gas and Wind Industry Projects with further growth on the horizon.

With the Forth (Rail) Bridge opening in 1890, the Forth Road Bridge in 1964 and the new Queensferry Crossing opening in 2017 our bespoke platforms are currently supporting the infrastructure from three centuries of crossings over the Firth of Forth.

Span Access Chairman, Kenny Wiggins said:

“Span has had an exciting year as we have supported these key projects, working on all three of these iconic bridges simultaneously shows our innovative capabilities with alternative access. Each of the bridges required a different solution, developed and installed exclusively to meet the needs of the client.”

Span Access has also received Expert Help assistance from Business Gateway Fife. Their adviser, Lynne Baillie, commented:

“Span has shown that it has ambitious plans for the future of its alternative access solutions business. Their work in a diverse range of sectors, including the recently announced Innovate UK backed offshore wind project proves the worth of their innovative approach to solutions for major infrastructure projects.”

Span Access has experienced significant growth in each of the last two years with a focus on Infrastructure, Oil & Gas and Wind Industry Projects with further growth on the horizon.

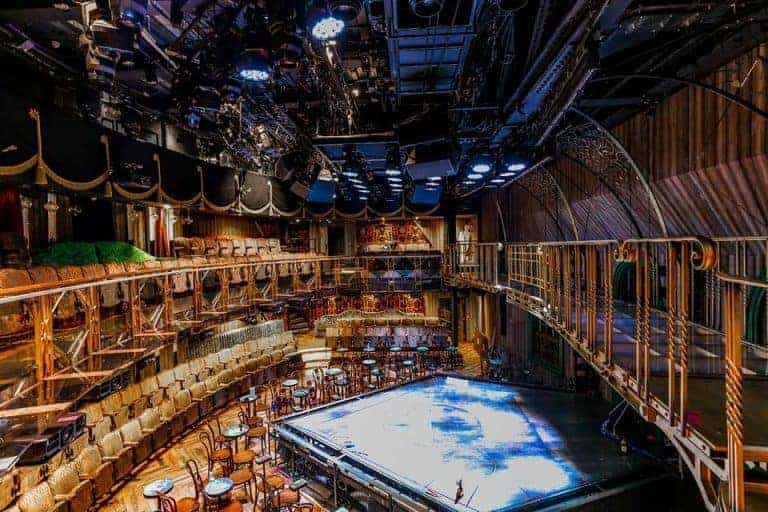

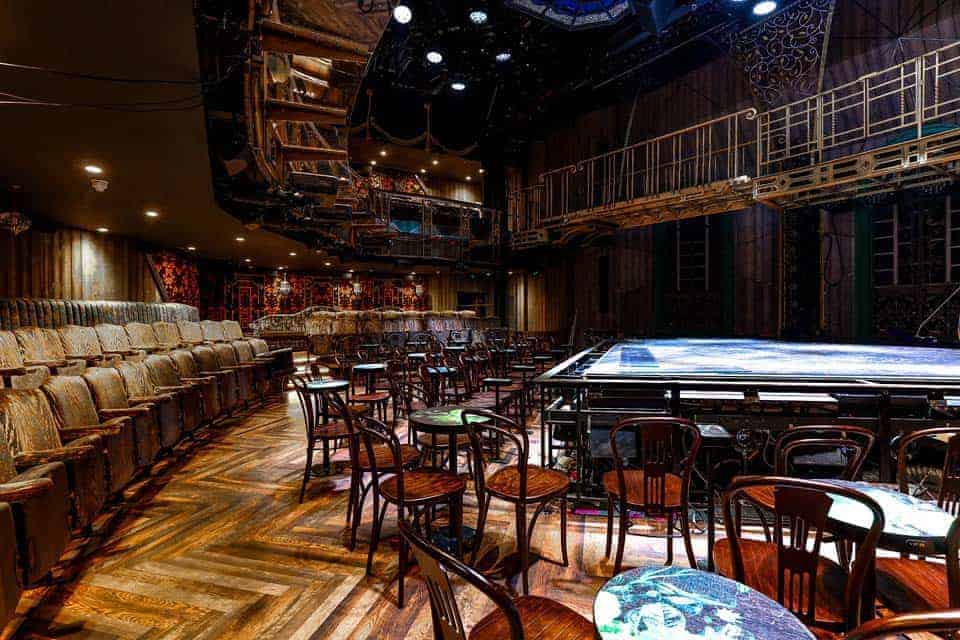

This new space required a large amount of demolition work and modification to the existing structure which all had to be sound-proofed along with installing new house lights.

Project 7 was also required to increase the seating capacity of this new theatre from 150 seats to 310 seats along with widening an existing mezzanine, installing a new spiral staircase and putting in various balconies, all of which allow the dancers to create the 360 degree show.

The company even took on additional tasks such as cutting slabs out of the stage to allow the performers to appear from below.

As if this wasn’t enough, Project 7 transformed a back bar of the venue to match the furnishings and feel of the new stage show.

All of this work had to be done while respecting the architectural history of the venue and gaining approval from the likes of The Theatres Trust.

Alan Brockhouse, CEO of the PHD Group which owns Project 7 said: ‘It was a huge challenge that took some innovative thinking and required us to be incredibly flexible in the way we worked.

‘At times the team was having to work in really cramped conditions to help ensure we didn’t disturb the customers.

‘Even bringing materials on and off the site required logistical planning as they had to ferry everything in and out a small entrance at the back so that they weren’t disturbing people.

‘It seemed that every part of the project had its own challenge.

‘We were determined not to disrupt the casino players and at one point built screened off scaffolding over the bar so that we could access the stage without being seen.’

This new space required a large amount of demolition work and modification to the existing structure which all had to be sound-proofed along with installing new house lights.

Project 7 was also required to increase the seating capacity of this new theatre from 150 seats to 310 seats along with widening an existing mezzanine, installing a new spiral staircase and putting in various balconies, all of which allow the dancers to create the 360 degree show.

The company even took on additional tasks such as cutting slabs out of the stage to allow the performers to appear from below.

As if this wasn’t enough, Project 7 transformed a back bar of the venue to match the furnishings and feel of the new stage show.

All of this work had to be done while respecting the architectural history of the venue and gaining approval from the likes of The Theatres Trust.

Alan Brockhouse, CEO of the PHD Group which owns Project 7 said: ‘It was a huge challenge that took some innovative thinking and required us to be incredibly flexible in the way we worked.

‘At times the team was having to work in really cramped conditions to help ensure we didn’t disturb the customers.

‘Even bringing materials on and off the site required logistical planning as they had to ferry everything in and out a small entrance at the back so that they weren’t disturbing people.

‘It seemed that every part of the project had its own challenge.

‘We were determined not to disrupt the casino players and at one point built screened off scaffolding over the bar so that we could access the stage without being seen.’

One of the biggest tasks of the refurbishment was building the large sound-proof acoustic wall which needed to sit behind the original theatre curtain which The Theatres Trust was keen to preserve.

Project 7 created a bespoke steel structure that curves over at the top to match the line of the theatre curtain. This structure then had rubber gaskets attached and plaster board fixed to both sides, with an air gap left in between, which all combined to create the acoustic wall. Again, this all had to be constructed while being screened off from the casino players below.

Scott Bannon, director of Project 7, said: ‘The acoustic wall would have been difficult enough to build anyway as it was an awkward space but we were then even more restricted as we didn’t want to disturb casino visitors.

‘Not only did it have to meet strict acoustic standards but it also had to be sturdy enough to withhold heavy stage equipment being attached to it as well as match the existing shape of the theatre curtain.

‘All the hard work has been worthwhile. The new theatre is amazing and when you see the dancers performing its really spectacular and uses every part of the space available.’

This major refurbishment work was completed in just 18 weeks with Project 7 staff working 24 hours for the final six weeks to ensure it was ready for the opening night.

One of the biggest tasks of the refurbishment was building the large sound-proof acoustic wall which needed to sit behind the original theatre curtain which The Theatres Trust was keen to preserve.

Project 7 created a bespoke steel structure that curves over at the top to match the line of the theatre curtain. This structure then had rubber gaskets attached and plaster board fixed to both sides, with an air gap left in between, which all combined to create the acoustic wall. Again, this all had to be constructed while being screened off from the casino players below.

Scott Bannon, director of Project 7, said: ‘The acoustic wall would have been difficult enough to build anyway as it was an awkward space but we were then even more restricted as we didn’t want to disturb casino visitors.

‘Not only did it have to meet strict acoustic standards but it also had to be sturdy enough to withhold heavy stage equipment being attached to it as well as match the existing shape of the theatre curtain.

‘All the hard work has been worthwhile. The new theatre is amazing and when you see the dancers performing its really spectacular and uses every part of the space available.’

This major refurbishment work was completed in just 18 weeks with Project 7 staff working 24 hours for the final six weeks to ensure it was ready for the opening night.

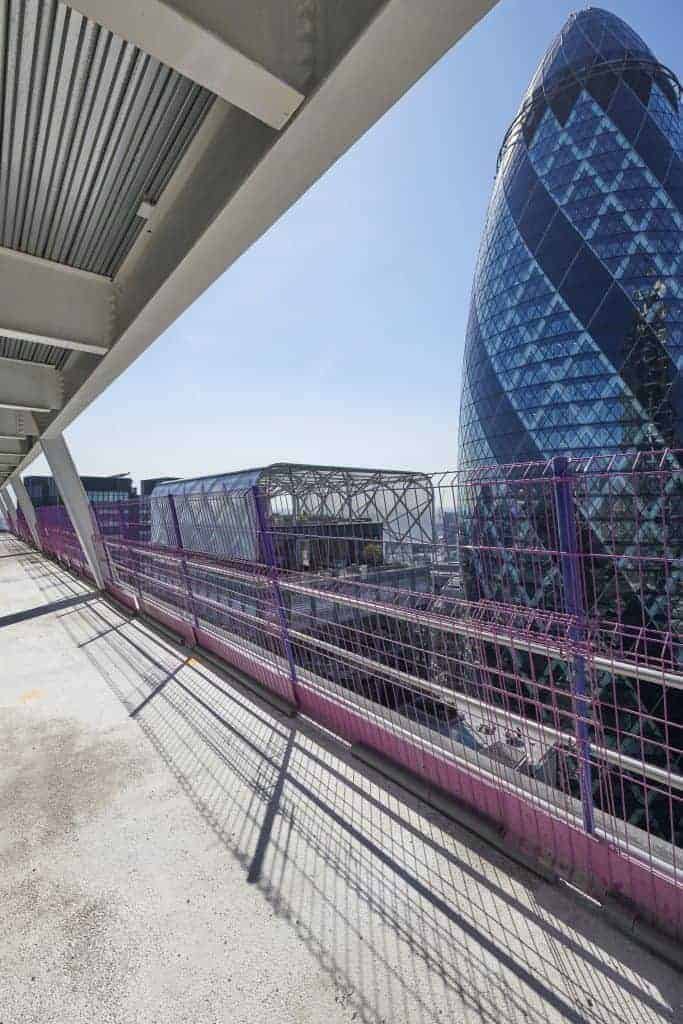

TRADGuard is a highly versatile system, with a range of attachments to suit a wide range of applications. The system boasts unrivalled strength, containment and flexibility, and is suitable for nearly all types of construction where temporary edge protection is required. To find out more, contact TRAD Safety Systems on 08450 50 70 50.

TRADGuard is a highly versatile system, with a range of attachments to suit a wide range of applications. The system boasts unrivalled strength, containment and flexibility, and is suitable for nearly all types of construction where temporary edge protection is required. To find out more, contact TRAD Safety Systems on 08450 50 70 50.

TRAD Safety System’s is part of the TRAD Group, which also comprises of TRAD Scaffolding Contractors and TRAD Hire & Sales. TRAD Safety Systems are the UK’s market leader in the design, manufacture and supply of innovative fall safety solutions for the building, construction and maintenance industries. With six depots nationwide, TRAD Safety Systems can effectively service any project in the UK.

TRAD Safety System’s is part of the TRAD Group, which also comprises of TRAD Scaffolding Contractors and TRAD Hire & Sales. TRAD Safety Systems are the UK’s market leader in the design, manufacture and supply of innovative fall safety solutions for the building, construction and maintenance industries. With six depots nationwide, TRAD Safety Systems can effectively service any project in the UK.